n. Center the discharge valve (9) and the discharge

valve spring (10) on the valve plate (8) and then position

the head assembly (14) on the valve plate so that the

inlet port is oriented to the front of the compressor

assembly and the screw holes in the crankcase (14, fig.

16), plunger and cylinder assembly (4, fig. 11)', and the

head assembly are in alinement. Secure the third stage

section with the four screws (16) and washers (15) and

apply a torque to screws between 60 to 65 pound inches

using the torque wrench and 9/64-inch socket wrench.

o. Assemble the second stage relief valve (17) to

the inlet port and the elbow (13) to the discharge port of

the head assembly (14).

Note

Final orientation of the elbow (13) and the

second stage relief valve (17.) is determined

during the assembly of the second stage

intercooler anti the aftercooler.

p. Position the preformed packing (18) and the

fourth stage plug (19) on the fourth stage port in the

crankcase (14, fig. 16) and secure with the four screws

(22, fig. 11) and washers (20). Apply a torque between

50 and 60 pound-inches to the screws using a 3/16-inch

socket wrench. Secure the screws after assembly using

a lockwire (21).

47. Testing

Prior to normal operation and use of the

compressor group in the overall unit, various test runs of

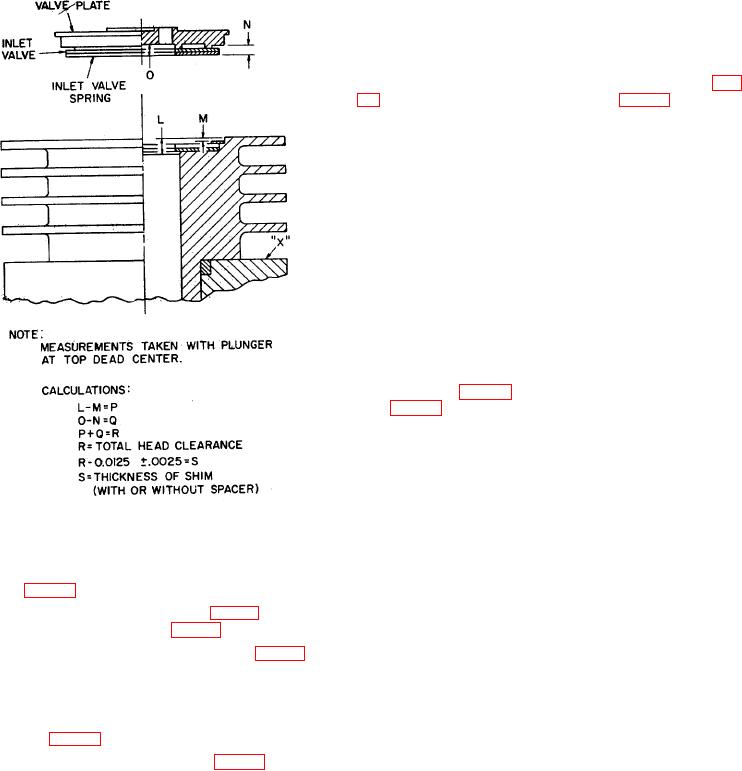

Figure 19. Third stage head clearance.

the compressor group must be accomplished. The type

of test run performed on the compressor group is

i. Remove the plunger and cylinder (4) from the

dependent upon the scope of replacement performed

crankcase (14, fig. 16).

during overhaul of the compressor group. In the event

j. Position the preformed packing (1, fig. 11) in the

that replacement of the crankcase, first stage piston, first

third stage port in the crankcase (14, fig. 16).

stage piston rings, second stage plunger or second

stage plunger rings is required, a four-hour special run is

k. Position the proper thickness of shim (2, fig. 11)

to be performed. If the third stage cylinder and plunger

with or without the spacer (3) to give the proper third

assembly is replaced in the compressor group the

stage head clearance, on the lower side of the third

performance of an eight-hour special run is required.

stage plunger and cylinder assembly (4) and position the

The replacement of any other pneumatic system parts

plunger and cylinder assembly in the third stage port in

require a one-hour minimum special run.

the crankcase (14, fig. 16).

l. Position the inlet valve spring (5, fig. 11), inlet

Caution

valve (6), gasket (7) and valve plate (8) on the plunger

Performance of the special runs are

and cylinder assembly (4).

accomplished when the compressor is

m. Position the gaskets (11 and 12) in the grooves

complete with coolers, brackets, fan and fan

on the head assembly (14).

guard and mounted on the test stand. The test

stand is used to perform all special runs.

AGO 5548A

31