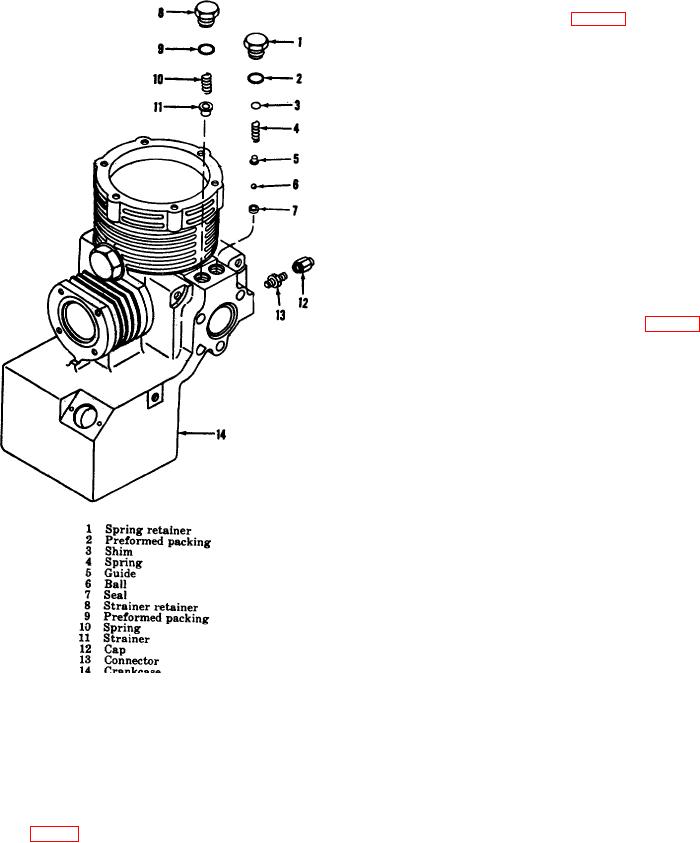

41. Crankcase Assembly (fig. 16)

a. Screw the connector (13) securely into the

crankcase (14) then assemble the cap (12) to the

connector.

b. Position the preformed packing (9) on the

strainer retainer (8).

c. Position the strainer (11), spring (10), into the oil

return port in the crankcase (14); secure the strainer

retainer (8) into the oil return port and tighten securely.

d. Position the preformed packing (2) onto the

spring retainer (1).

e. Position the seat (7), ball (6), guide (5), spring

(4), shim (3) into the oil pressure relief port in the

crankcase (14); screw the spring retainer (1) into the oil

pressure relief port and tighten securely.

42. Keystone-Crankshaft Assembly (fig. 15)

a. Using an arbor press, press the front bearing

(13) and rear bearing (7), one at a time, onto the

crankshaft (11) until the bearings shoulder.

Caution

Exert pressure on the inner race of the

bearings only, to prevent damage to the

bearing's rotating elements during installation.

b. Position the upper keystone (8) and lower

keystone (10) ("F" on both components facing the fan

end on the compressor) onto the keystone bearing

surface of the crankshaft (11); secure in place by

pressing the two rollpin assemblies (9) into the keystone

bearing surface of the crankshaft; press the two rollpin

assemblies into the keystone assembly (23). The gaps

in the two rollpin halves should be oriented 180 apart

during installation and pressed flush with the keystone

assembly surface.

Note

Figure 16. Crankcase, exploded view.

The upper and lower keystone are selective fits

and are not interchangeable with similar parts.

40. Lubrication

During assembly if the keystone assembly

a. Apply oil (OE-0) to all preformed packings.

binds on the crankshaft, it may be loosened by

tapping the upper and lower keystone with a

b. Apply oil (OE30) to all threaded areas.

plastic or rawhide mallet.

c. Apply oil (OE-30) to all wear surfaces.

c. Position the plate (14) onto the crankshaft (11) in

d. Apply oil (OE-30) to the front and rear bearings

front of the front bearing .(13).

(7 and 18, fig. 15).

d. Insert the pin (12) into the crankshaft (11) and

position the gerotor assembly (15) onto the pin.

AGO 65348A

26