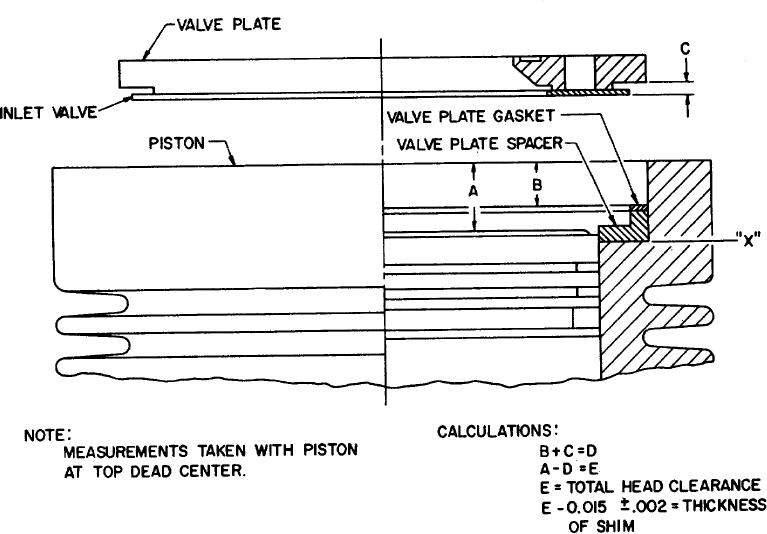

Figure 17. First stage head clearance.

f. Position the intake valve (2) on the intake valve

k. Position the preformed packing seal (11) in the

seating surface on the valve plate (15) and measure the

groove in the head assembly (7)

distance from the valve to the flat on the valve plate.

l. Position the discharge valve spring (12),

Record this value as the "C" value.

discharge valve (13) and discharge valve se (14) on the

g. Determine the total available first stage head

head assembly (7) and secure An place by using the

clearance by adding the values of "B" and "C" obtaining a

screw (17), gasket (16), washer (10), and nut (9). Apply

sum value equal to "D".

a torque to the nut until the hole in the screw is alined

Subtract the value of "D" from the value of "A" and obtain

with the hole if the nut. Position the cotter pin (18) into

a remainder value of "E. This value "E" is the total head

the alined holes and bend the cotter pin over the nut and

clearance for the first stage.

along the screw. The maximum permissible torque on

the nut is .8 pound-feet.

h. Subtract the required first stage head clearance

of 0.015 + .002 inches from the "E" value and record this

m. Position the head assembly (7) on the valve

value as the thickness of shim (4).

plate (15) and orient the outlet port in the head assembly

i. Remove the spacer (3) and gasket (1) from the

120 to the left from the dead front point on the first

first stage cylinder bore.

stage cylinder and aline the screw holes in the head

assembly with the screw holes in cylinder.

j. Position the shim (4), spacer (3), intake 28 valve

(2), gasket (1), and valve plate (15) into the first stage

cylinder bore.

AGO 5548A

28