Section VI.

ENGINE GROUP

49. Description and Function

The engine group is a one-cylinder, four-stroke

cycle, overhead valve, aircooled, gasoline fueled unit

designed to develop hp at 3,600 rpm. Included with

the gasoline engine are various accessory components

required to facilitate operation of the unit. The splined,

engine adapter is secured to the drive shaft of the

gasoline engine and is used to drive the crankshaft of the

compressor assembly. The tube assembly is secured to

the frame assembly by a clamp and is attached to the

shutoff cock and the filter and connector. The tube

assembly is used to conduct the fuel from the fuel tank to

the carburetor of the gasoline engine. Attached to the

gasoline engine are four clip angles which are used to

mount the gasoline engine to the frame assembly. At the

rear of the gasoline engine is attached the pulley. The

pulley is used with the rope starter to manually start the

gasoline engine.

50. Maintenance

Fourth echelon maintenance personnel are

authorized to replace the adapter, tube assembly, clamp,

clip angles, pulley, and gasoline engine. For detail

maintenance of the gasoline engine, refer to TM 5-2805-

206-14.

a. Removal.

(1) Perform the disassembly authorized in

paragraph 16a.

(2) Disconnect the aftercooler (6, fig. 9) from the

water separator inlet elbow (12, fig. 3).

(3) Unscrew the eight bolts (10, fig. 20), washers

(9) and remove the engine group and

compressor group from the lower frame (9,

(4) Unscrew the four bolts (2, fig. 10) and

washers (1, fig. 10) and remove the

compressor group from the engine group (4,

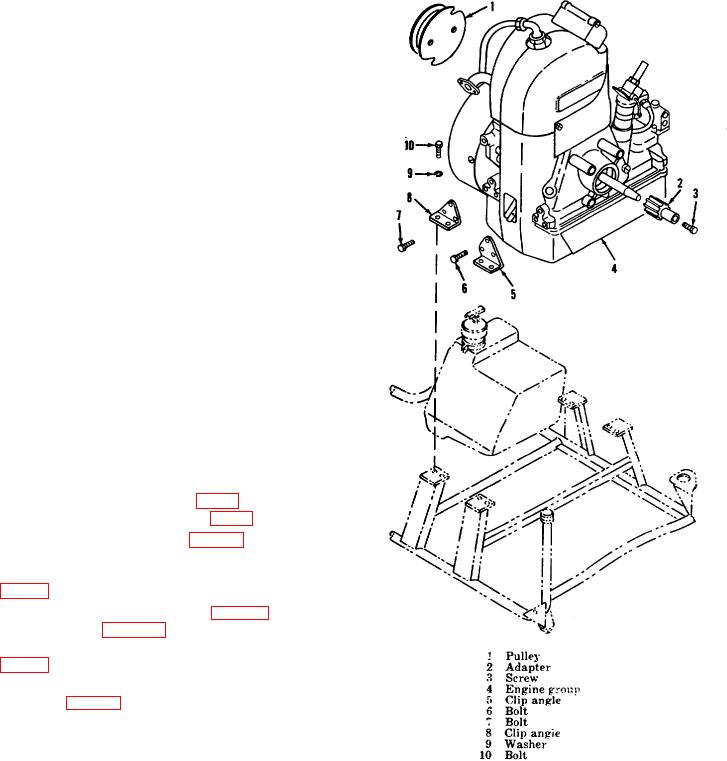

b. Disassembly (fig. 20).

(1) Unscrew the screw (3) and remove the

adapter (2) from the gasoline engine (4).

(2) Unscrew the screws on the gasoline engine

Figure 20. Engine group, partial exploded view.

(4) holding the pulley (1) and replace the

attaching screws on the gasoline engine (4).

(3) Unscrew the six bolts (6) and remove the two

clip angles (5) from the gasoline engine (4).

AGO 5548A

33