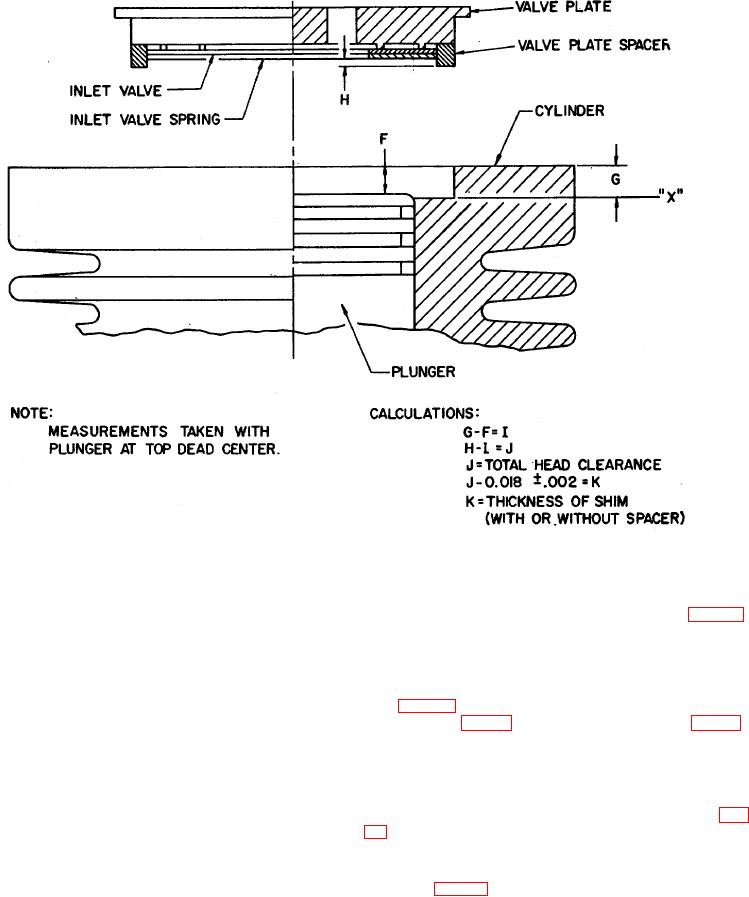

Figure 18. Second stage head clearance.

Secure the head assembly to the first stage cylinder with

a. Determine the thickness of shim (15, fig. 12)

the six screws (5) and washers (6). Apply a torque of 30

required to give a proper second stage head clearance

to 35 pound-inches to the screws using the torque

between 0.016 and 0.020 inches as described in b

wrench and 9/64-inch socket wrench.

through h below. Refer to figure 18.

n. Position the preformed packing (23) in the

b. Insert the second stage plunger subassembly

groove on the cap (22).

(17, fig. 12) into the 2d stage cylinder bore of the

o. Position the filter assembly (24), cap (22) and

cap (21) on the head assembly (7) and secure with four

using a suitable size hexagonal bar stock, so that the

screws (19) and washers (20). Apply a torque to the

plunger is at top dead center.

screws between 17 and 22 pound-inches.

c. Using a depth micrometer, measure the distance

p. Assemble the outlet elbow (8) to the outlet port

from the flat surface of the second stage cylinder to the

of the head assembly (7).

top of the second stage plunger subassembly (17, fig.

12). Record this value as the value "F."

Note

d. Measure the distance from the flat surface of the

second stage cylinder to the flat seating surface of the

Final orientation of the elbow is not

shim (15, fig. 12) in the second stage bore. Record this

determined until assembly of the first stage

value as the value "C."

intercooler.

e. Position the inlet valve (11) on the inlet 29

45. Second Stage Assembly

AGO 5548A

29