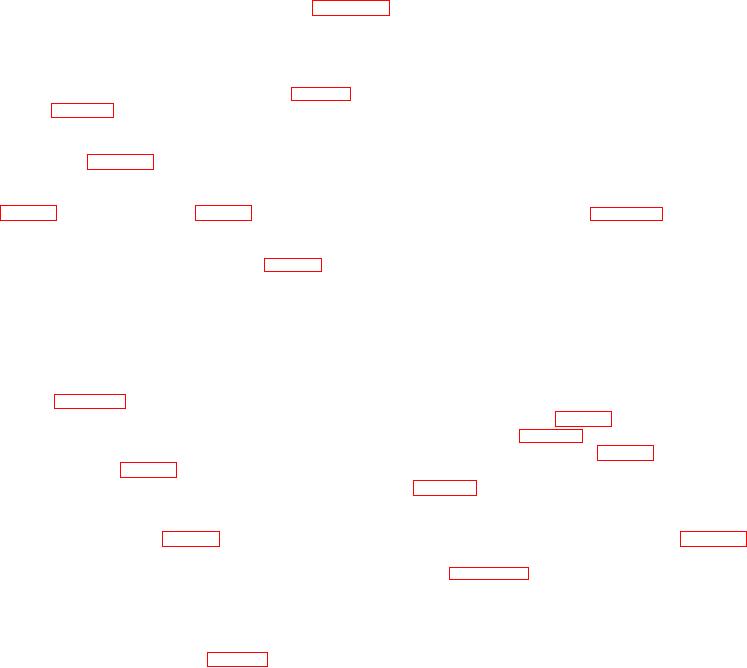

TM 3-1040263-34

1

Elbow

9

Stop shim

17

Inlet valve

2

Nut

10

Stop shim

18

Plate gasket

3

Washer

11

Stop shim

19

Preformed packing

4

Stud

12

Head

20

Shim

5

Intercooler bracket

13

Outlet spring

21

Shim

6

Intercooler bracket

14

Outlet valve

22

Shim

7

Intercooler bracket

15

Head gasket

23

Cylinder

8

Valve disk stop

16

Plate and pin

Figure 4-6-Continued

ance must be between 0.040 and 0.045 inch. The head

(22) Rotate crankshaft to lower piston in

clearance is determined as indicated in (9) through (13)

cylinder. Position plate gasket (18), intake valve (17),

below.

and plate and pin (16) into cylinder (23). Insure intake

(9) Obtain result of C minus B (fig. 4-8).

valve (17) is free.

Piston (6, fig. 4-7) must be at top dead center when

(23) Position the head gasket (15) and

establishing dimension B.

outlet valve (14) on the plate and pin (16).

(10) Subtract

this

dimension

from

(24) Position the outlet spring (13) on the

dimension D (fig.

4-8) to obtain available head

center of the outlet valve (14).

clearance.

(25) Position the assembled valve disk stop

(11) Select additional shims (20, 21, and

(8), stop shims (9, 10, and 11), and head assembly (12)

22, fig. 4-6) to add to surface G (fig. 4-8) to adjust result

on the cylinder (23). Using figure 4-9 as a guide, position

obtained in preceding step (10). This gives proper head

the first-stage outlet port 510 to the left of the rear of the

clearance A (0.040 to 0.045 inch).

compressor when facing front of unit. With head

(12) Remove the two nuts (2, fig. 4-6), and

assembly positioned, aline intake hole passages in valve

remove studs (4) and cylinder (23). Then, position shims

plate (16) with hole passages in first-stage head (12).

(20, 21, and 22) and reassemble the cylinder, using the

Secure the positioned parts, using three studs (4, fig. 4-

removed nuts and studs. Recheck head clearance.

6) that do not support brackets (5, 6, and 7), washers (3),

(13) When proper head clearance is

and nuts (2). Tighten studs (4) to a torque of 39.6

obtained, remove the nuts (2), studs (4), cylinder (23),

pound-inches. Tighten nuts (2) to a torque of 30 pound-

and shims (20, 21, and 22).

inches.

(14) Measure dimensions P, R, and T

(26) Position first-, second-, and third-stage

indicated in figure 4-8.

heat exchangers on compressor. Aline brackets (5, 6,

(15) Obtain result of R minus T minus P

and 7) on first stage (fig. 4-9). Assemble with remaining

which equals discharge valve travel.

three studs (4, fig. 4-6), washers (3), and nuts (2).

(16)

Use correct thickness of stop

Secure aftercooler clamp (3, fig. 3-3) at location A using

shims (9, 10, and 11, fig. 4-6) and valve disk stop (8) to

screw (2) and nut (1). Apply specified torque to tighten

limit discharge-valve travel between 0.015 and 0.021

inch.

(27) Assemble first-stage strainer and filter

(17) Apply compress or oil lightly to the first-

(TM 3-1040-263-12).

stage compression rings (5, fig. 4-7).

(28) Assemble fan group (para 4-7). (29)

Perform testing (e below). (30) Assemble protecting

(18) Position the four compression rings (5)

cage (para 3-7d). (31) Perform 0 to 2, 000 psi tank fill

into the ring grooves of the first-stage piston (6) so that

the compression-ring gaps are approximately 900 apart.

operation (TM 3-1040-263-12). (32) Assemble canvas

group (TM 3-1040-263-12).

NOTE

e.

Testing.

Assemble three studs (4, fig. 4-6), not

used with intercooler brackets (5, 6, or

7), to the crankcase to facilitate alining

holes during assembly.

(19) Lubricate all parts with compressor oil

prior to assembly.

(20) Position shims (20, 21, and 22) and

preformed packing (19) onto cylinder (23).

(21) Position cylinder (23) with assembled

parts onto crankcase first-stage port alining mounting

holes.

4-13

TM 3-1040-263-34