TM 3-4310-100-20 & P

(5) Reinstall the drain plug.

the connection between the engine and compressor.

(6) Remove the oil breather cap. Clean the

Return compressor units with oil leaks to direct support

cap and filter at each oil change in dry cleaning solvent

maintenance personnel. Observe the oil level through

(stoddard solvent) per Federal Specification P-D680.

the oil level sight or on the dipstick full mark. Keep the

type 1 (AN-M4B and AN-M4C models only). Air dry

oil level at full.

before replacing the cap.

(9) Wipe the spilled oil from the compressor unit.

(7) Fill the reservoir with one pint of air

compressor lubricating oil (table 1-1) and reinstall the

2-8. Gasoline Engine

breather cap or dipstick.

Refer to TM 5-2805-256-14 and LO 5-2805-256-12 for

(8) Start the compressor (TM 3-4310-100-10)

lubrication instructions on the gasoline engine.

and operate for 5 minutes. While the compressor is

running, look for oil leaks around the drain plug and at

Section Ill. PAINTING

c. Touch up all painted exterior surfaces with

2-9. General

rust-inhibiting enamel (item 5, Appendix F).

Organizational maintenance personnel are authorized to

paint or touch up all painted exterior surfaces of the

NOTE

compressor unit.

2-10.

Painting Instructions

Additional detail painting instructions

a. Remove scratches, rust, scales, chips, and

for field use are contained in TM 43-

foreign matter from surfaces to be touched up or painted.

0139, Painting Instructions for Field

b. Prime all worn, scratched, or bare metal

Use.

surfaces with vinyl-zinc chromate primer (item 2,

Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

and services for each interval is shown in the work time

2-11.

General

column. These times are stated in hours and tenths.

Organizational maintenance personnel are responsible

for performing quarterly preventive maintenance checks

and services on the compressor units (table 2-1). The

2-12.

Deficiencies

numbers under the "Sequence Number" column indicate

Report all deficiencies beyond

the scope of

that the service opposite the number must be performed

organizational

maintenance

to

direct

support

in the numerical sequence at the prescribed interval.

maintenance personnel.

The man-hour time required to perform all the checks

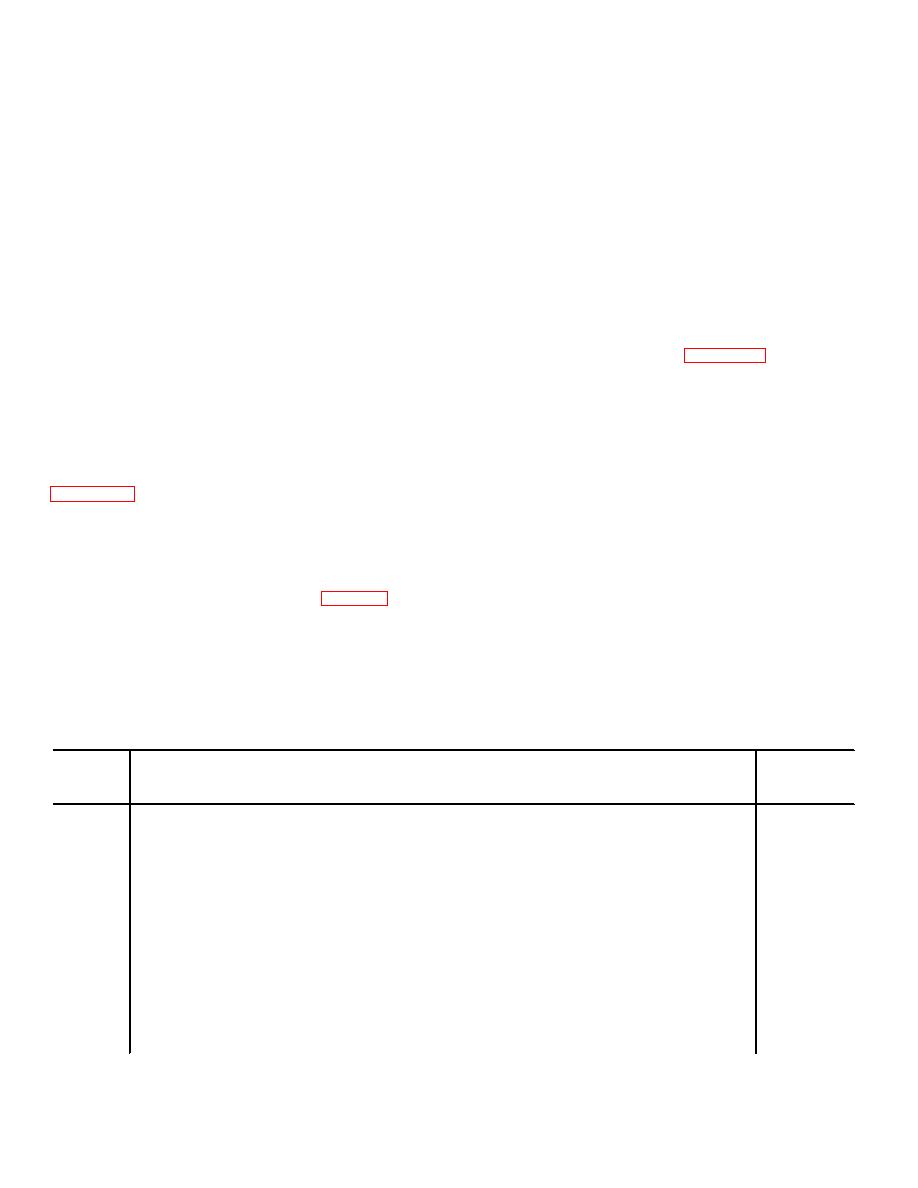

Table 2-1. Preventive Maintenance Checks and Services

Quarterly

Total Man Hours required: 1.4

Sequence

Items To Be Inspected

Work Time

Number

Procedure

(M/ H)

Section I. CANVAS

Man-hours required:

0.2

CANVAS COVER, BACK REST HARNESS

AND STRAP ASSEMBLIES.

Check for holes, rips, fraying or other damage. Replace "missing items or items

considered unsafe for use. Check for worn, damaged, or loose hardware securing strap

assemblies to engine mounting frame. Replace damaged or missing hardware.

Section II. TOP FRAME AND BOTTOM FRAME

Man-hours required:

0.2

Inspect for cracks, broken welds and missing mounting hardware. Check condition of

painted surfaces. Touch up chipped, scratched and rusted painted areas. Check for

damaged or missing rubber mounts.

2-6