b. Cleaning and Inspection. Clean all parts

breaks, the key for chips and burs,

and the threaded surfaces for wear

with an approved cleaning solvent, and dry

and damage. See that the key fits

thoroughly. Inspect all parts for dents or

snugly in the keyway.

breaks, Inspect the nuts and bolts for stripped

(3) Replace all defective parts.

threads and worn heads. Replace any defective

c. Installation.

part.

c. Instullution.

(1) Position the machine key (4) in the

crankshaft.

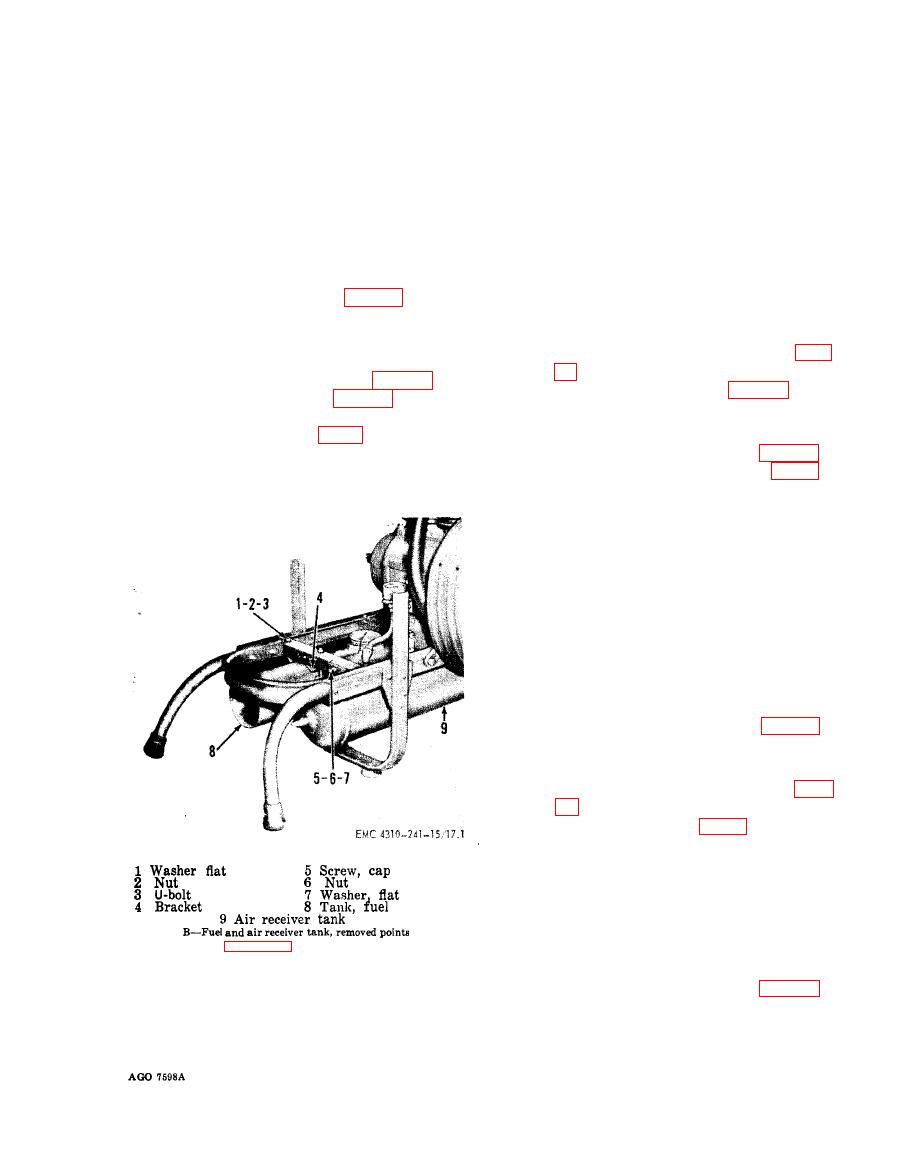

(1) Position the fuel tank under the hand

truck and secure with two U-bolts and

(2) Fit the key slot in the drive pulley (5)

nuts.

over the machine key, and press the

(2) Install the fuel line (par. 75).

pulley in position on the shaft. Lock

the pulley in position by tightening the

set screw.

LP-512-ENG)

(3) Install and adjust the V-belts (par.

a. Removal.

(1) Remove the V-belt guard (par. 82).

(4) Install the V-belt guard (par. 82).

(2) Remove the V-belts (par. 83).

(2) Remove the set screw that locks the

drive pulley (5, A, fig. 18) to the en-

a. Removal.

gine crankshaft. Use a suitable puller

(1) Remove the gasoline engine (par. 66).

to remove the pulley and lift out the

(2) Remove the twelve screws (6, fig. 13)

machine key (4),

that secure the front and rear mount-

ing brackets (7) to the engine. Re-

move the brackets from the engine.

b. Cleaning, Inspection, and Repair. Clean

all parts with an approved cleaning solvent, and

dry thoroughly. Inspect all parts for dents and

breaks. Inspect the bolts for stripped threads

and worn heads. Replace any defective parts.

c. Installation.

(1) Install the front and rear engine

mounting brackets (7) and secure the

brackets to the engine with twelve

screws (6) and lockwashers.

(2) Install the gasoline engine (par. 66).

a. Removal.

(1) Remove the gasoline engine (par.

(2) Remove the cap (9, fig. 13) and drain

the oil from the engine.

b. Cleaning and Inspection. Clean all parts

with an approved cleaning solvent, and dry

thoroughly. Inspect all parts for cracks or

breaks. Replace any defective parts.

c. Installation.

Figure 17-Continued.

(1) Install the cap (9) in the bottom of

the engine oil pan.

b. Cleaning and Inspection.

(2) Install the gasoline engine (par. 66).

(1) Clean the pulley and key with an ap-

(3) Fill the crankcase with the proper

proved cleaning solvent and dry

grade of oil in accordance with the

thoroughly.

current lubrication chart.

(2) Inspect the pulley for cracks and