TM 5-4310-247-15

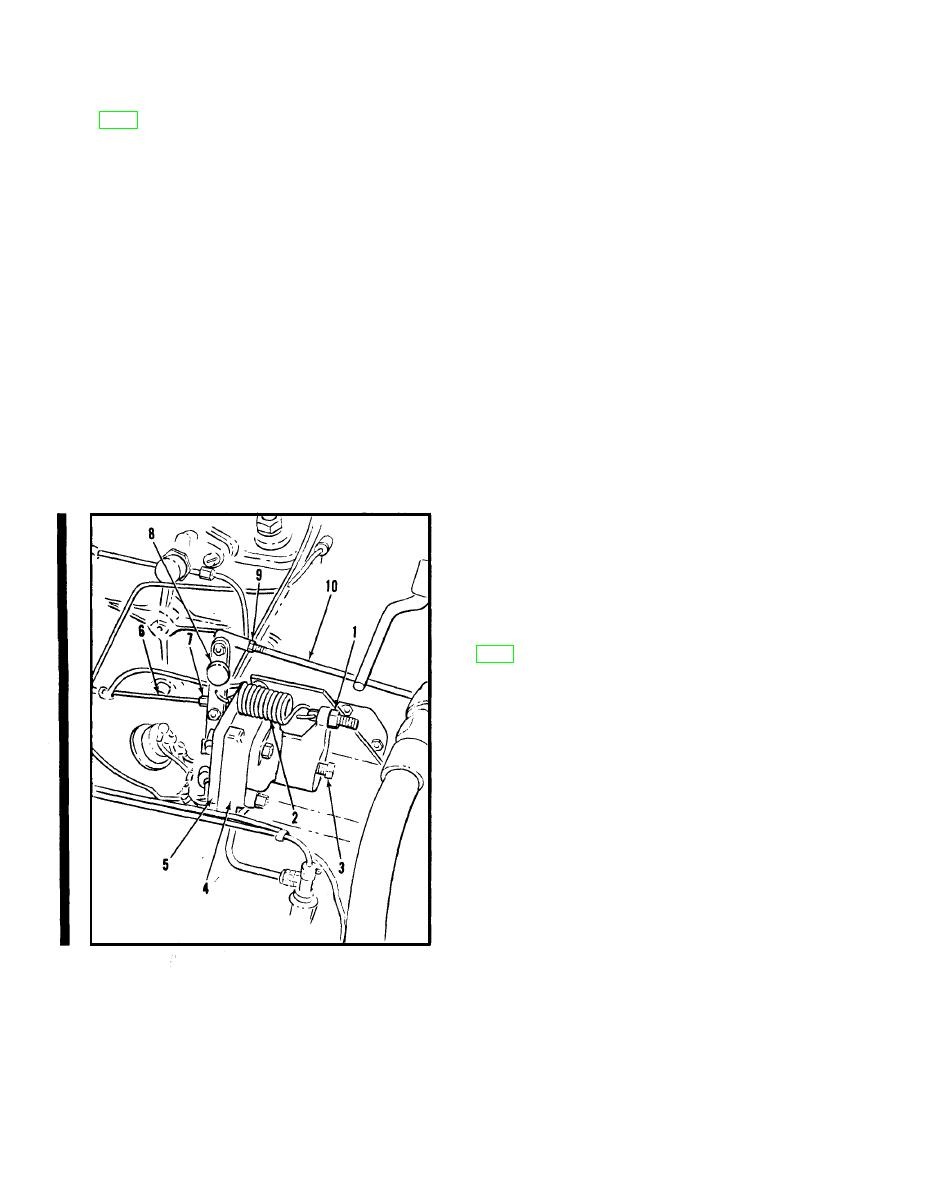

b. Speed Adjustment.

(1) Lower receiver pressure to 100 psi by

a. Pressure Adjustment.

bleeding air with a service valve. En-

(1) Before starting the engine, turn nut

gine will speed up.

(1, fig. 26) clockwise, finger tight, to

(2) Loosen locknuts (7) on linkage rod

obtain a small amount of tension in

(6) and turn rod to obtain 1,800 rpm.

spring (2) and to hold lever (8)

It may be necessary to change setting

against control diaphragm retainer

of service air valves to maintain 100

(5).

psi during speed adjustment. Tighten

(2) With engine running and thoroughly

locknuts. If lever (8) moves away

warmed up, slowly close all service

from contact with control diaphragm

air valves and allow compressor to

retainer (5) tighten nut (1) several

unload. It may be necessary to loosen

turns or turn screw (3) clockwise

ball joint locknuts (9) and shorten

slightly. If this condition persists after

rod (10) to prevent engine from stall-

lowering the receiver pressure to 90

ing.

psi, report the condition to direct sup-

(3) Turn screw (3) clockwise to raise re-

port maintenance. Practically no air

ceiver pressure to approximately 110

should leak from the bleed hole in the

psi.

body (4) when operating at full speed

and pressures of 100 psi or below.

(3) Close service valves to unload compres-

sor. Loosen locknuts on rod (10) and

turn rod to obtain an idle speed of ap-

proximately 1,050 rpm at 110 psi re-

ceiver pressure. Retighten locknuts.

Note. The engine must be properly tuned,

thoroughly warmed up, with proper grade of

fuel and oil, relatively clean fuel filters end

air filter prior to air control adjustment.

a. General. This valve is placed in the system

to prevent oil from draining back into the com-

pressor during shut-down. Discharge air pres-

sure holds the valve open during operation, per-

mitting oil to circulate through the system.

Upon shutdown, the loss of air pressure allows

the spring-loaded valve to close.

b. Removal.

(1) Refer to figure 28 and remove the oil

control valve.

(2) Remove nipple (2, fig. 27).

c. Disassembly. Refer to figure 29 for dis-

assembly of the oil control valve.

d. Cleaning and Inspection.

(1) Clean all parts with an approved

cleaning solvent; dry thoroughly.

(2) Inspect all parts for wear or damage,

repair or replace if unserviceable.

6 Linkage rod

1 Nut

e. Reassembly. Refer to figure 29 and re-

7 Locknut

2 Spring

assemble the valve.

8 Lever

3 Screw

9 Locknut

4 Air control assembly

f. Installation. Refer to figure 28 and install

10 Linkage rod

5 Diaphram retainer

the valve.

Figure 26. Air control service.

* U.S. GOVERNMENT PRINTING OFFICE: 1992 643-016/60023

44

Change 4