Section XII. VALVE ADJUSTMENT

81.1. General

This section contains valve adjustment and

valve tappet clearance data.

81.2. Valve Adjustment

a. Disconnect rod (10, fig. 26) and spring

(2) from lever (8) to decrease idling speed.

c. After valve adjustment has been completed

TEMPERATURE IS REACHED. REFER

connect rod (10, fig. 26) and spring (2) to

TO PAR. 14.

lever (8).

STEP 2. REMOVE CYLINDER HEAD COVER.

REFER TO FIGURE 18.

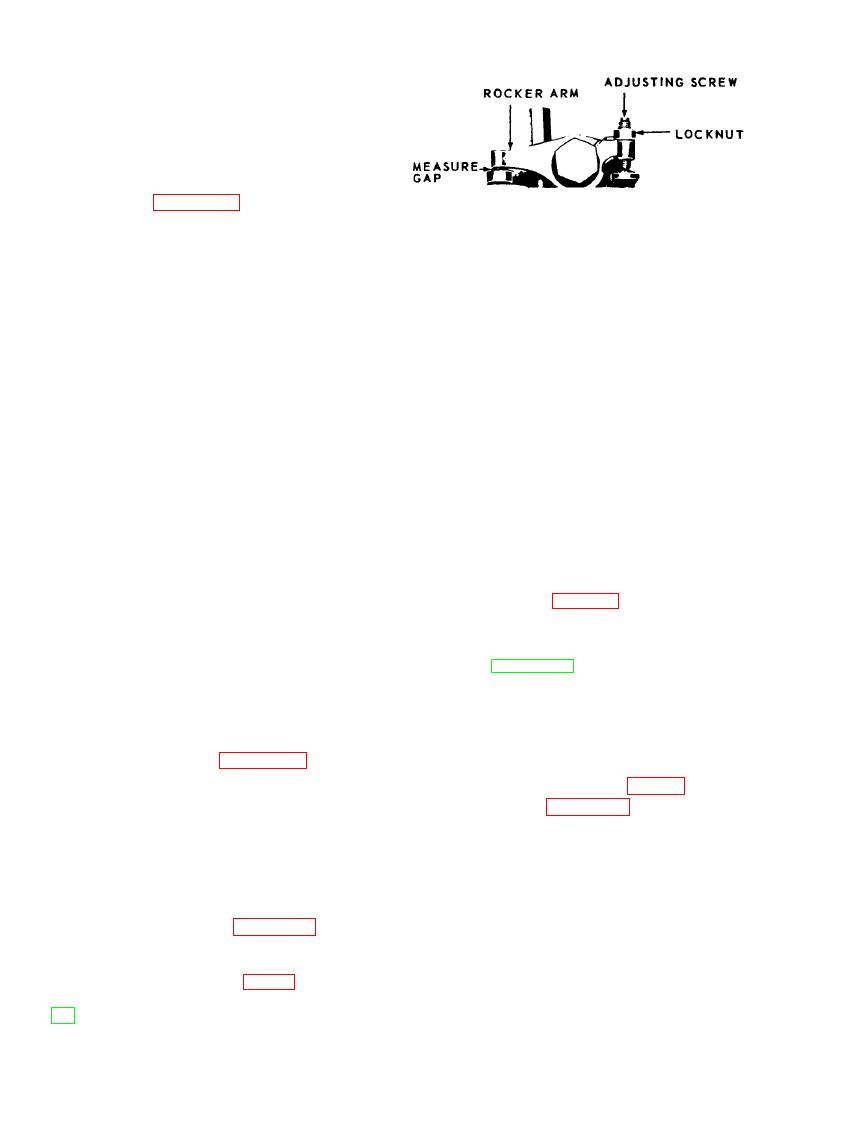

STEP 3. WITH A FEELER GAGE MEASURE CAP

FOR CLEARANCE. PROPER VALVE

TAPPET CLEARANCE IS 0.014 IN.

(HOT).

STEP 4. ADJUST ROCKER ARMS AS NECESSARY

BY LOOSENING LOCKNUT AND TURN-

ING ADJUSTING SCREW CLOCKWISE TO

DECREASE CLEARANCE, AND COUNTER

CLOCKWISE TO lNCREASE CLEARANCE.

STEP 5. TIGHTEN LOCKNUT AFTER ADJUSTING

AND CHECK CLEARANCE.

STEP 6. READJUST AS NECESSARY.

STEP 7. INSTALL CYLINDER HEAD COVER.

REFER TO PAR. 14.

MEC 4310-247-15/30.1

Section XIII. ENGINE LUBRICATION SYSTEM

81.3. Oil Cooler

81.4. Oil Filter

a. Removal.

engine oil cooler.

(1) Remove oil cooler (para 81.3).

b. Cleaning and Inspection.

(2) Refer to figure 30.2 and remove en-

(1) Clean the oil cooler with an approved

gine oil filter.

cleaning solvent; dry thoroughly.

b. Cleaning and Inspection.

(2) Inspect for dents, cracks, breaks, cor-

(1) Clean the engine oil filter assembly,

rosion, or other damage.

except element and gasket, with an ap-

(3) Replace gaskets and damaged mount.

proved cleaning solvent; dry thor-

ing hardware.

oughly.

(2) Inspect all parts for cracks, breaks,

engine oil cooler.

dents, or other damage.

Note. After reinstallation of engine oil cooler bring

(3) Replace gaskets.

cooling system to proper level (para 40).

AGO 8166A