tive during inspection. Screw the en-

ergy cell body (14) on the end of a

piece of wood, then insert the cell into

the cylinder head, lapping the energy

cell body to the seat.

Note. The seat in the cylinder head must

be gastight, since it is a point at which the

cell is sealed into the head. Any leakage will

cause burning of the surrounding metal in a

short time.

(6) Lap the mating surfaces between the

energy cell caps and the energy cells

to insure an airtight seal.

(7) Position the energy cell bodies (14),

caps (13), and retainers (12) in the

cylinder head assembly (36), and se-

cure with the energy cell plugs (11).

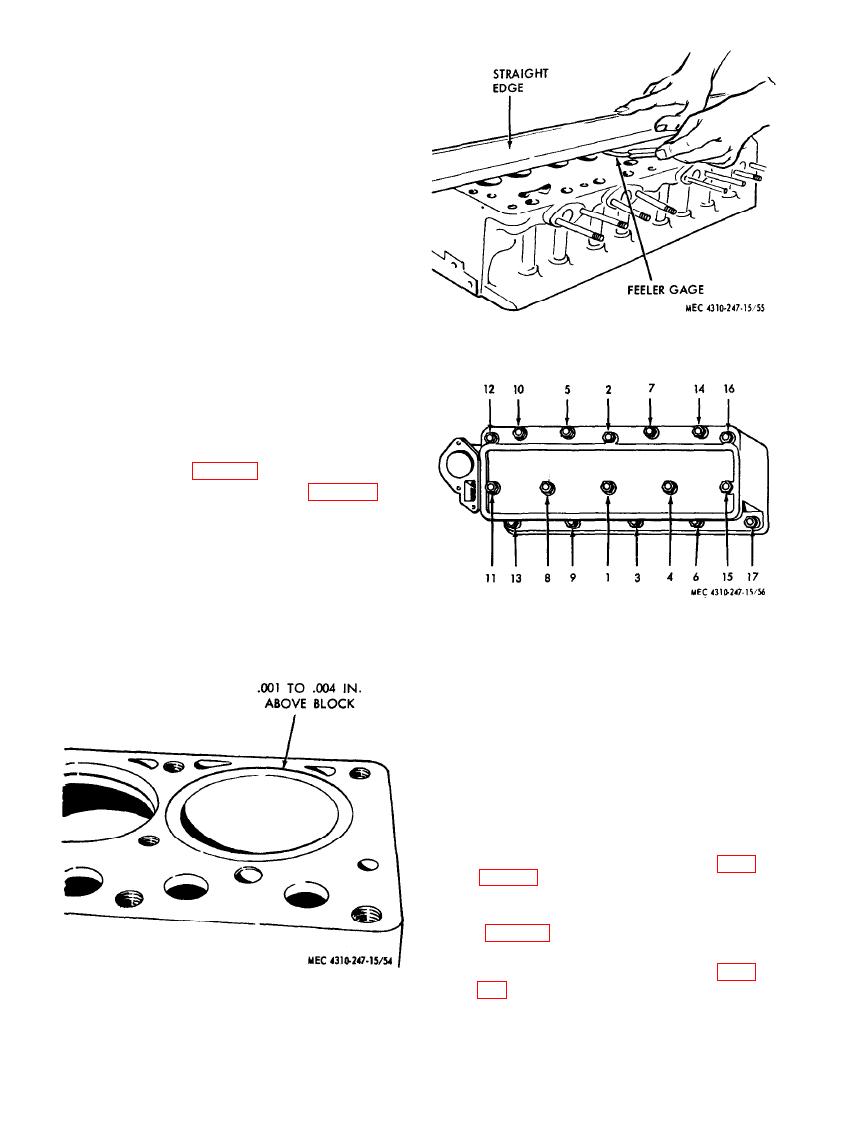

Figure 55. Cylinder head inspection.

Tighten plug, and torque to 100 foot-

pounds.

(8) If it was necessary to remove the fuel

injection nozzle holders in order to

drive the energy cells out of the-cylin-

der head, replace the nozzle holders at

this time (para 130).

(9) Replace valve assemblies (para 134)

and check gasket contact surfaces on

the head (36, fig. 50) and block (69),

making sure they are clean, smooth,

and flat.

Note. Check flatness with straight edge

and feeler gage in three positions lengthwise

and five crosswise (fig. 55). The maximum

Figure 56. Cylinder head tightening sequence.

permissible is .004 inch low in the center

lengthwise, gradually decreasing toward the

ends, and .003 inch crosswise or in localized

low spots. Cylinder head or block must be

resurfaced if these limits are exceeded.

Note. Use new cylinder head gasket (37,

fig. 50). If difficulties are encountered with

gasket sealing, coat both sides of gasket with

heat resisting aluminum paint and assemble

immediately.

(10) Using a chain hoist, lower the cylinder

head assembly (36) evenly over the

studs, then pull all cylinder head nuts

down snug with speed wrench and

tighten with torque wrench.

Note. Refer to the tabulated data of para-

three stages, in the sequence shown in fig. 56.

(11) Connect injection and leak-off lines

(12) Reassemble and install valves, push

rods, and rocker arm assembly (para

Figure

54.

Cylinder

sleeve

reassembly.

AGO 8166A

84