TM 5-4310-350-14

10

4

TS 013629

12

13

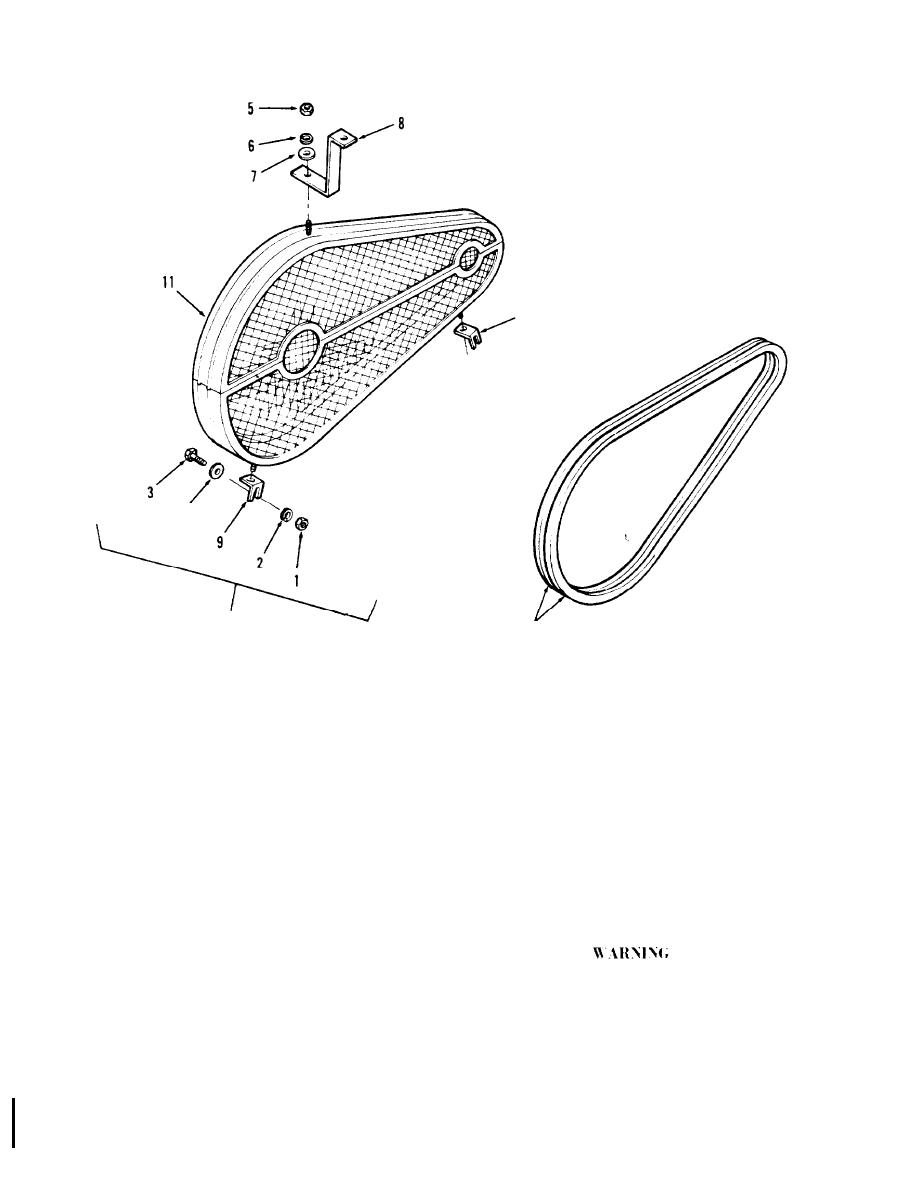

10. Bracket

7 . Washer, flat (3)

4 . Washer, flat (2)

1. Nut, hex (2)

11 Guard, belt

8 . Bracket

5. Nut, hex (3)

2 . Lockwasher

12. Belt guard assembly

9 . Bracket

6. Lockwasher (3)

3 . Capscrew (2)

13. V-belts

Figure 3-5. Belt guard assembly.

3-9. Air Intake Muffler

clean and lubricated at all times. If the com-

p r e s s o r is allowed to become dirty it will run

a. General. The air intake muffler is designed

hot. Excessive heat will consume the compressor

to clean the air entering the first stage cylinder.

oil. LO w oil causes the rings to wear, or cylinder

Should the operating area be exceptionally dusty,

scoring.

Therefore, frequent inspections are

the muffler must be serviced more frequent] }-.

necessary.

A clogged intake muffler reduces the efficiency

of the compressor.

Inspection

b). Cleaning and Inspection.

(1) Visually

inspect

for

excess

accumulation

of dirt and oil.

(2)

signs of

Check

safety

relief

valve

leaking.

Dry cleaning solvent, PD-680, used to

( 3 ) Listen for cxcessive start-stop cycling.

clean parts is potentially dangerous to

( 4 ) Listen carefully for a k n o c k o r rattle

personnel and properly. Avoid repeated

that might indicate internal damage.

Do not use

and prolonged skin contact.

( 5 ) If any of the troubles listed i n para-

near open flame or exressive heat. Flash

graphs 3, 4, and ,5 are found, notify organizational

p o i n t of solvent is 100 F. -- 138 F

(38

C

--

59

C).

3-10