TM

5-4310-350-14

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. EXCESSIVE STARTING OR STOPPING

Step 1. Check receiver for condensate,

Refer to paragraph 3-10 and drain the condensate.

Step 2. Check for air leaks in piping, or the receiver check valve leaking.

Repeat Step 1 in paragraph 3 above.

Notify Direct Support Maintenance.

6. COMPRESSOR RUNNING HOT

Step 1. Check that air passage is not blocked at fan wheel.

Remove any foreign objects that may be blocking ventilation.

Step 2. Check for a leaking check valve.

Refer to paragraph 4-16 and replace a defective cheek valve.

7. COMPRESSOR RUNNING SLOW

Step 1. Check for low line voltage, or a defective motor starter heater.

Tighten loose connections. If the compressor still runs slowly, notify Direct Support Maintenance.

Step 2. Check for a leaking release valve.

Refer to paragraph 4-14 and replace a leaking release valve.

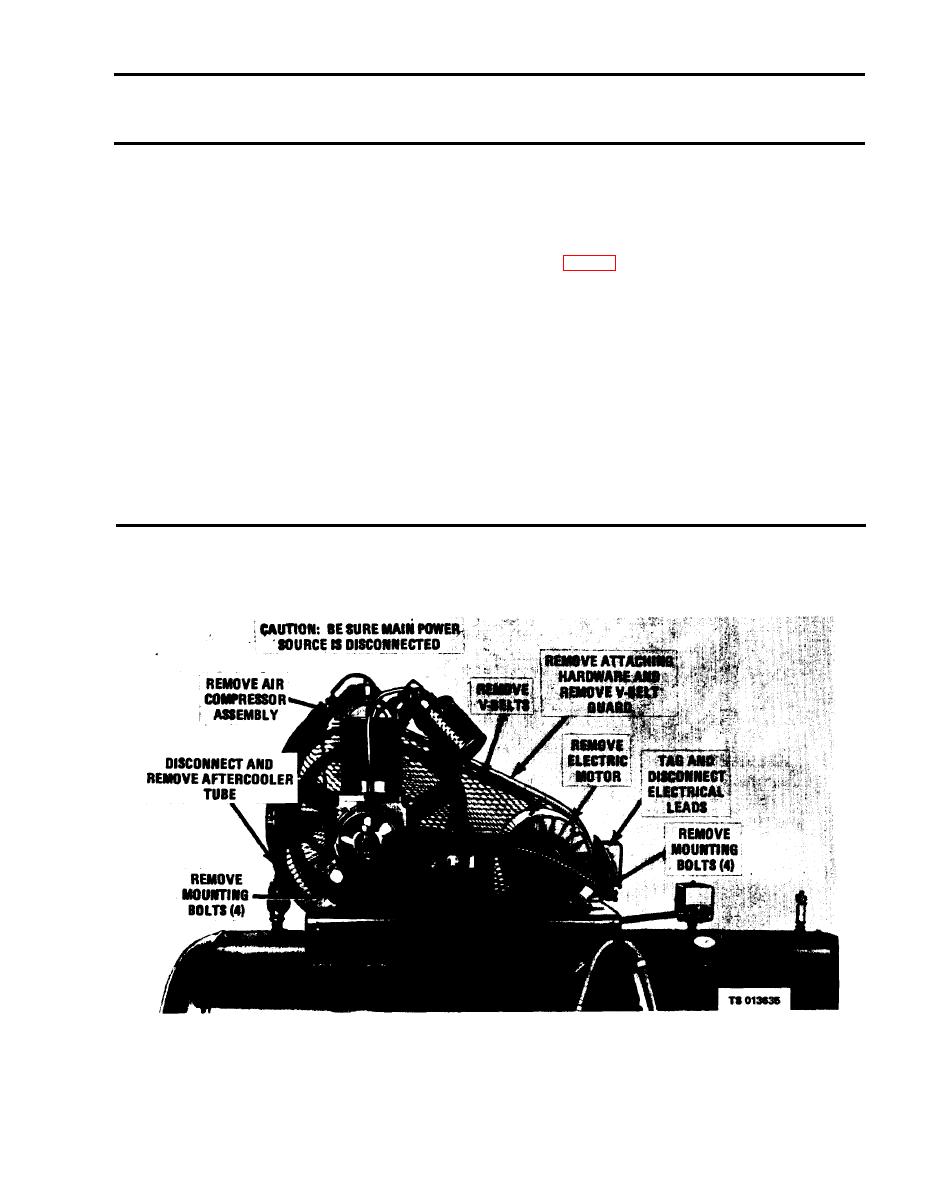

Section VI. MAINTENANCE OF THE ELECTRIC MOTOR AND COMPRESSOR