TM 5-4310-354-14

REMOVAL

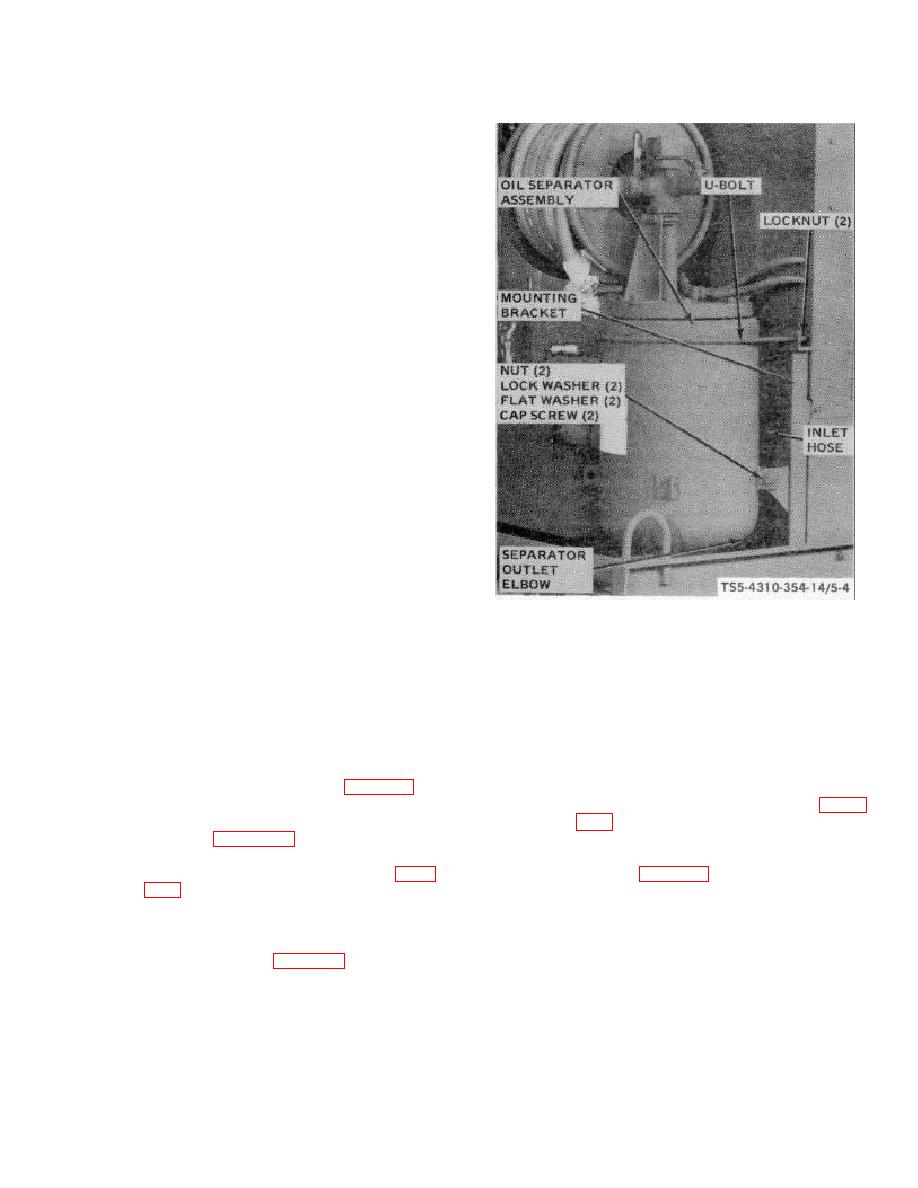

STEP 1.

DISCONNECT OIL HOSE ASSEMBLY

FROM SEPARATOR OUTLET ELBOW.

STEP 2.

LOOSEN HOSE CLAMPS, DISCONNECT

AND REMOVE SEPARATOR INLET HOSE.

STEP 3.

REMOVE LOCKNUTS AND U-BOLT.

STEP 4.

REMOVE NUTS, LOCK WASHERS , CAP

SCREWS, AND FLAT WASHERS THAT

SECURE

SEPARATOR

TANK

TO

BRACKET.

REMOVE

THE

OIL

SEPARATOR ASSEMBLY.

INSTALLATION

STEP 1.

INSTALL OIL SEPARATOR ASSEMBLY in

POSITION AND SECURE SEPARATOR

TANK TO MOUNTING BRACKET WITH

FLAT WASHERS, CAP SCREWS, LOCK

WASHERS, AND NUTS.

STEP 2.

INSTALL U-BOLT AND SECURE WITH

LOCK NUTS.

TS5-4310-354-14/5-4

STEP 3.

INSTALL SEPARATOR INLET HOSE AND

TIGHTEN HOSE CLAMPS.

STEP 4.

CONNECT OIL HOSE ASSEMBLY TO

SEPARATOR OUTLET ELBOW.

Figure 5-4. Compressor oil separator assembly, removal and installation.

b. Installation.

5-10.

Blowdown Valve Assembly.

(1) Attach a suitable lifting device to the

a. Removal.

compressor oil separator assembly and

install on the unit as shown in figure 5-4.

(1) Disconnect air hose assemblies from

blowdown valve assembly fittings (figure

(2) Connect the air hoses to fittings on top of

separator (figure 4-22).

(2) Remove the blowdown valve assembly as

(3) Install the hose reel assembly (para

shown in figure 5-5.

4-25.f.).

(4) Fill the oil separator tank with proper

grade of lubricating oil in accordance with

LO 5-4310-354-12, figure 3-1.

5-20