TM 5-4310-354-14

5-11.

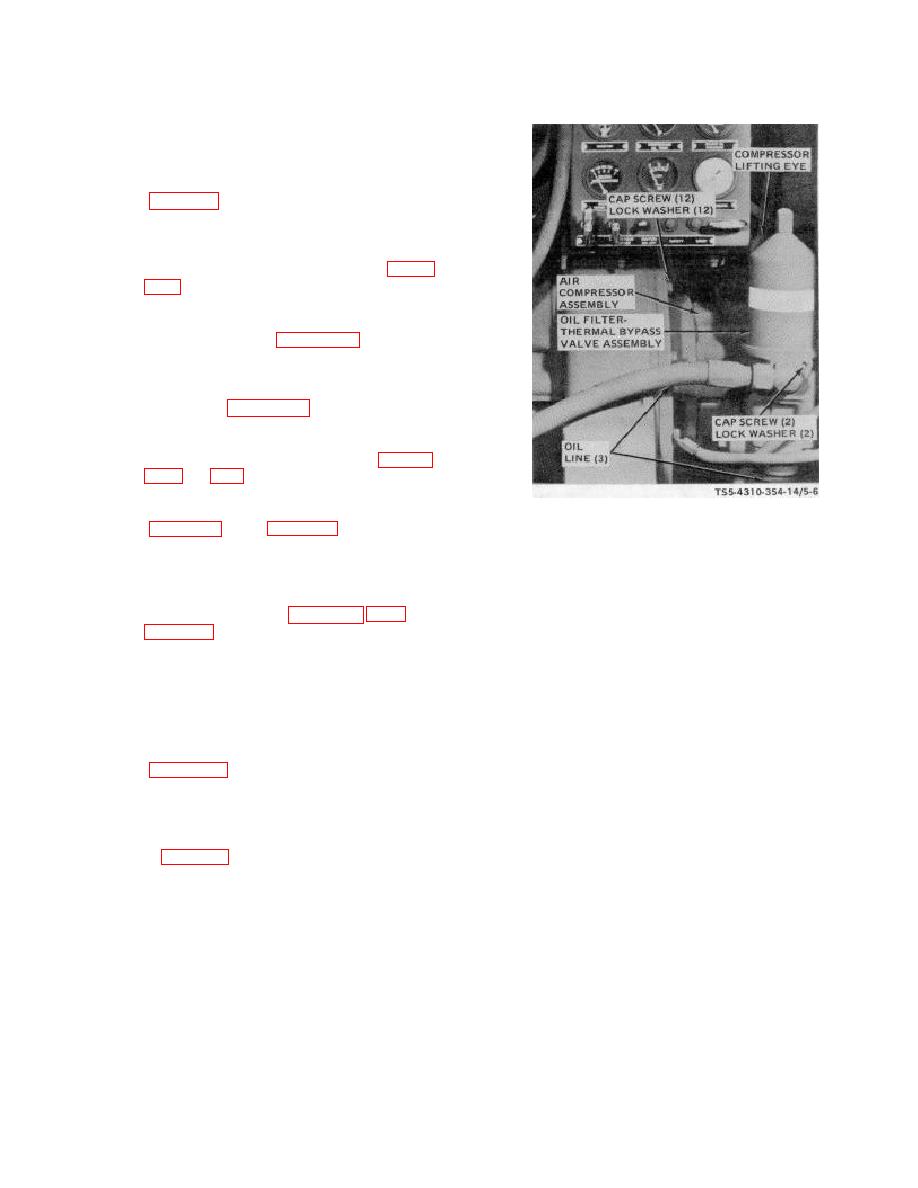

Air Compressor Assembly.

a. Removal.

(1) Remove the

engin e

(2) Remove the exterior components on

compressor enclosure as necessary to

gain access to the air compressor (figure

(3) Remove the engine and compressor air

cleaner assemblies (figure 4-15).

(4) Disassemble com pressor enclosure to the

extent necessary to gain access to the

compressor (figure 4-17).

(5) Disconnect and remove compressor air

intake lines, hoses, and fittings (figures

TS5-4310-354-14/5-6

(6) Remove the blowdown valve assembly

REMOVAL

STEP 1.

DISCONNECT

OIL

LINES

FROM

(7) Remove compressor oil temperature

THERMAL BYPASS VALVE ASSEMBLY.

shutdown switch and oil temperature

REMOVE

CAP

SCREWS,

LOCK

sensing bulb. Disconnect and remove oil

WASHERS,

OIL

FILTER-BYPASS

separator inlet hose (para 4-56, 4-70 and

ASSEMBLY AND GASKET.

STEP 2.

REMOVE CAP SCREWS AND LOCK

WASHERS.

CAREFULLY

MOVE

(8) Disconnect compressor unloader control

COMPRESSOR ASSEMBLY AWAY FROM

cable and idle control cable (para 4-63).

ENGINE TO DISCONNECT DRIVE PINS

AND BUSHINGS.

(9) Disconnect speed control rod return

spring. Disconnect speed control rod stop

STEP 3.

LIFT AIR COMPRESSOR OUT OF UNIT.

block from compressor unloader lever

INSTALLATION

(10) Attach suitable lifting device to eyebolt on

STEP 1.

POSITION AIR COMPRESSOR ON UNIT.

top of compressor stator and remove air

ALIGN COMPRESSOR DRIVE COUPLING

compressor assembly from unit as shown

WITH DRIVE PINS AND BUSHINGS ON

in figure 5-6.

ENGINE FLYWHEEL.

STEP 2.

INSTALL LOCK WASHERS AND CAP

SCREWS

ATTACHING

AIR

COMPRESSOR ASSEMBLY TO ENGINE

FLYWHEEL HOUSING.

STEP 3.

INSTALL A NEW GASKET, OIL FILTER-

BYPASS VALVE ASSEMBLY, ATTACH

ASSEMBLY TO COMPRESSOR WITH

LOCK

WASHERS AND CAP SCREWS.

CONNECT OIL LINES.

Figure 5-6. Air compressor assembly, removal and

installation.

5-22