TM 5-4310-354-14

b. Installation.

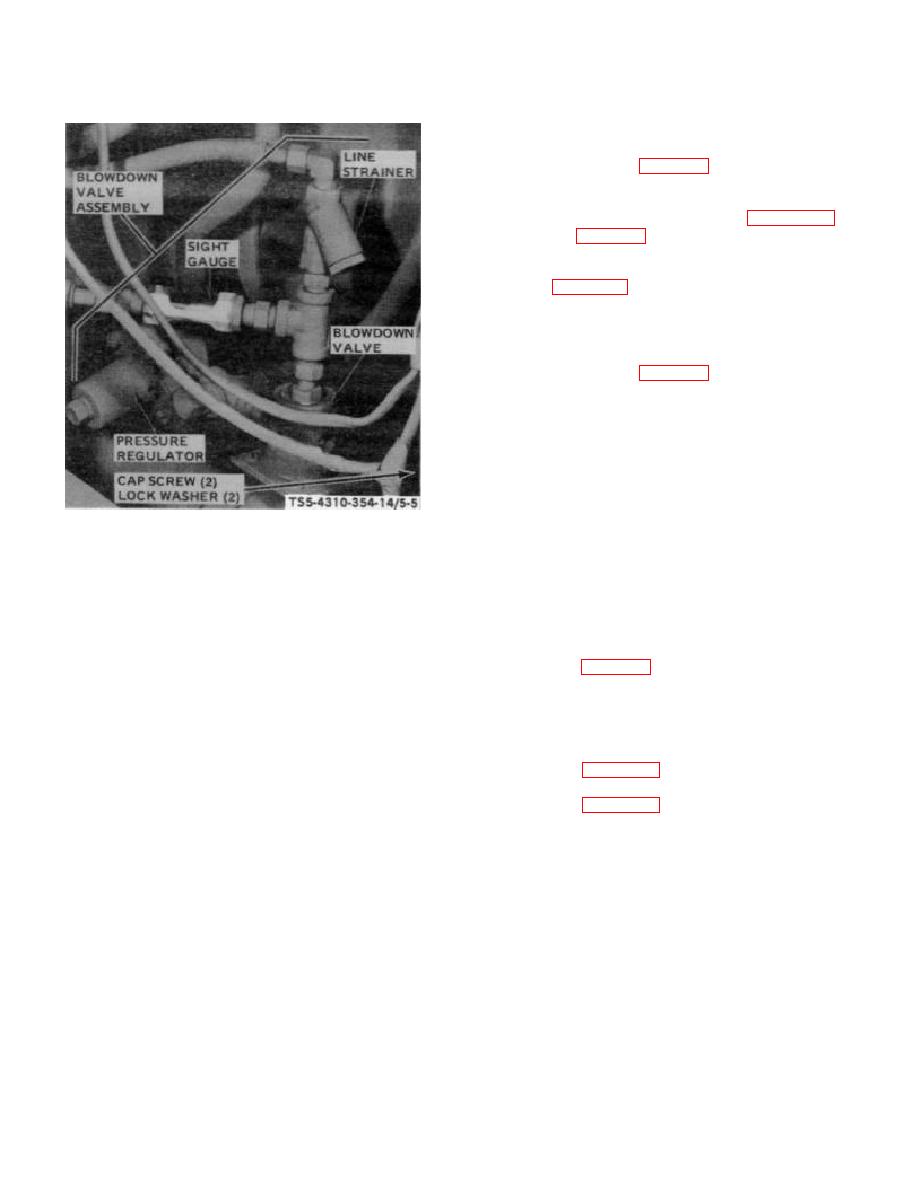

(1) Install the blowdown valve assembly as

shown in figure 5-5.

(2) Connect air hose assemblies to blowdown

valve assembly fittings (figure 4-22 and

c. Testing.

Testing of the blowdown valve

assembly (figure 5-5) is to be done after installation in

order to produce actual operating conditions.

The

function of this assembly is in direct relation to pressure

in oil separator tank and within the compressor air

intake. After the assembly is installed, and air pressure

regulator is adjusted (para 6-7. d), test the blowdown

valve assembly as follows:

(1) With unit operating and service valves

closed, test all hose connections for air

leaks by applying a soapy water solution

with a brush. Leakage will be indicated by

bubbling of the solution.

Tighten all

TS5-4310-354-14/5-5

connections.

REMOVAL

(2) Allow the unit to run at least until full

pressure is attained in separator tank and

STEP 1.

REMOVE CAP SCREWS AND LOCK

compressor automatically unloads. Again

WASHERS THAT SECURE BLOWDOWN

check blowdown valve for leakage.

VALVE ASSEMBLY TO COMPRESSOR.

(3) While unit is operating, either in load or

STEP 2.

REMOVE THE BLOWDOWN

VALVE

unload mode, observe the sight gauge

ASSEMBLY FROM UNIT.

oil mixture seen.

INSTALLATION

(4) Cycle the air compressor several times by

STEP 1.

INSTALL BLOWDOWN VALVE ASSEMBLY

opening and closing the air service valve

IN POSITION ON UNIT.

on the oil separator. Then, stop the unit

STEP 2.

INSTALL LOCK WASHERS AND CAP

on instrument panel and blowdown valve

SCREWS

SECURING

BLOWDOWN

VALVE ASSEMBLY TO COMPRESSOR.

relieved through the blowdown valve and

the pressure gauge should indicate no

Figure 5-5. Blowdown valve assembly, removal and

pressure within 30 to 45 seconds.

Installation.

5-21