TM 5-4310-354-14

(2) If the slip rings are dirty, they may be

cleaned and finished with 400 grain, or finer,

polishing cloth.

CAUTION

The rotor must be rotated when

cleaning or finishing the slip rings so

that they are cleaned evenly.

Cleaning by hand without spinning

the rotor may result in flat spots on

the slip rings causing brush noise.

TS5-4310-354-14/7-6

Spin the rotor and hold polishing cloth

against the slip rings until they are clean.

Slip rings which are rough or out of round

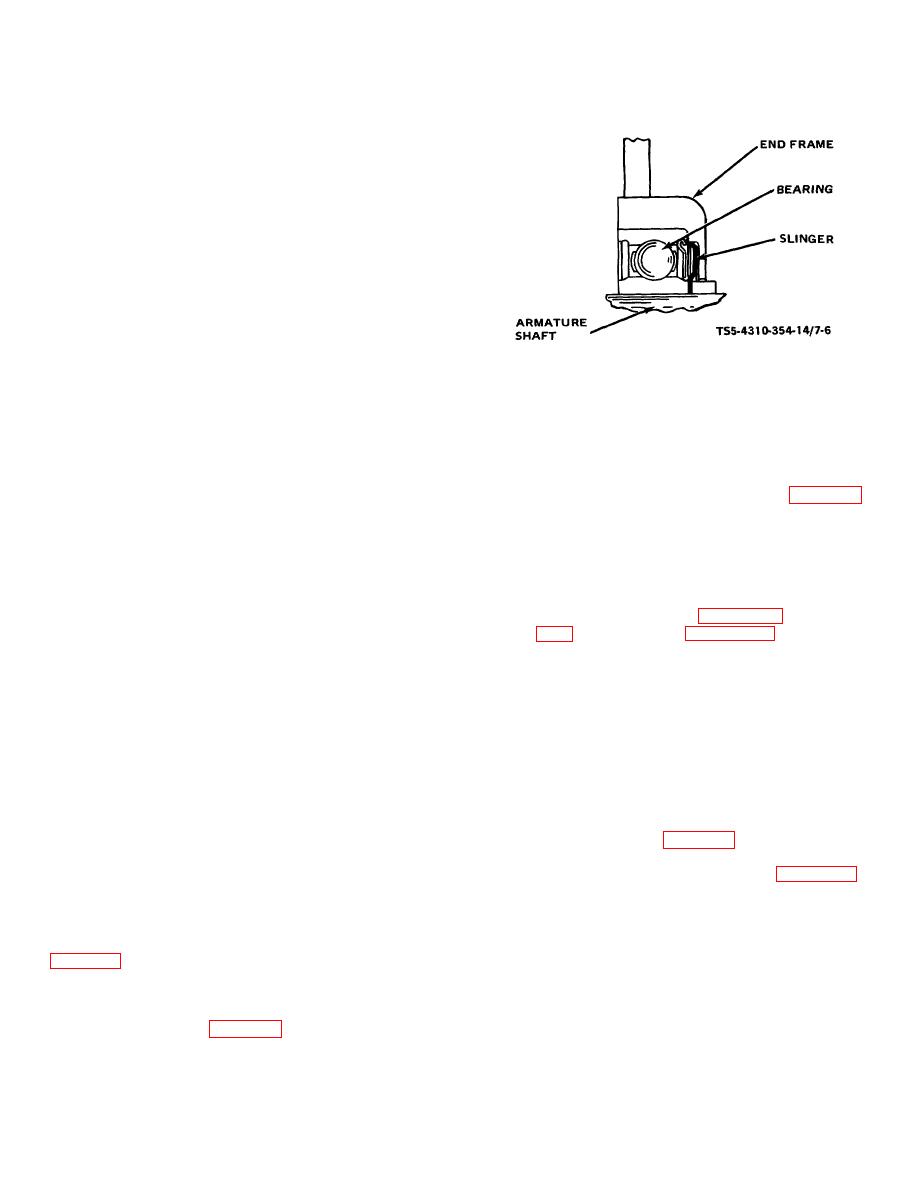

Figure 7-6. Drive end bearing assembly.

should be trued in a lathe to 0.002 inch

(0.051 mm) maximum indicator reading.

a tube or collar that just fits over the outer

Remove only enough material to make the

race. Fill cavity between bearing and

slip rings smooth and round. Then, finish

retainer plate with lubricant equal to

with 400 grain, or finer, polishing cloth.

Delco-Remy No. 1948791.

Blow away all polishing dust with clean,

dry compressed air.

(2) Reassemble inside collar (34, figure 7-1)

and a new retainer plate (33) if the felt

(3) Inspect brushes for cracks, chips, and

seal is hardened, worn, or otherwise

excessive wear. Replace the brush and

defective. Attach with three screws (32).

holder assembly when brushes are worn

to less than 1/4-inch (6.35 mm).

NOTE

(4) Inspect brush springs for cracks, breaks,

At reassembly refer to figures 7-3 and

distortion, or any other defect.

reassembly order of parts.

(5) Inspect bearings for freedom of rotation,

any gritty action, wear, or any other defect.

(3) Reassemble a new bearing (30) in slip

ring end frame (31) using a flat plate over

(6) Inspect rotor bearing journals for wear, scoring,

the bearing and press in from the outside

pitting, or any other defect.

toward the inside of the frame until bearing

is flush with outside of end frame. Support

(7) Check all parts for cracks,

breaks,

the inside of the end frame with a hollow

distortion, damaged threads,

burned

cylinder to prevent breakage of the frame.

insulation, or any other defects.

Use care to avoid misalignment of

bearing. Reassemble terminal package

(8) Repair of the alternator, other than that

(29), refer to figure 7-4, for order of parts.

detailed above, is limited to the

replacement of defective parts, or the

(4) Reassemble regulator (28, figure 7-1),

entire assembly.

brush spring (27), brush and holder (26),

insulator (25), insulated screw (24), two

e. Reassembly.

Reassemble the alternator

lock washers (23) and two screws (22).

assembly in the reverse numerical sequence shown in

(5) Reassemble capacitor (21) into capacitor

bracket (20) ; attach with screw and lock

(1) Reassemble grease slinger (36) and

washer (19), lock washer (18), and screw

bearing (35) into drive end frame (7) as

(17).

shown in figure 7-6. Press bearing in with

7-6