TM 5-4310-354-14

(8) Operate alternator at moderate speed and

adjust carbon pile as required to obtain

maximum output.

(9) If output is within 10 amperes of rated

output, test regulator with an approved

regulator tester, and check field winding.

(10) If output is not within 10 amperes of rated

output, check the field winding, diode trio,

rectifier bridge, and stator as outlined in

g. Installation.

Install the alternator assembly

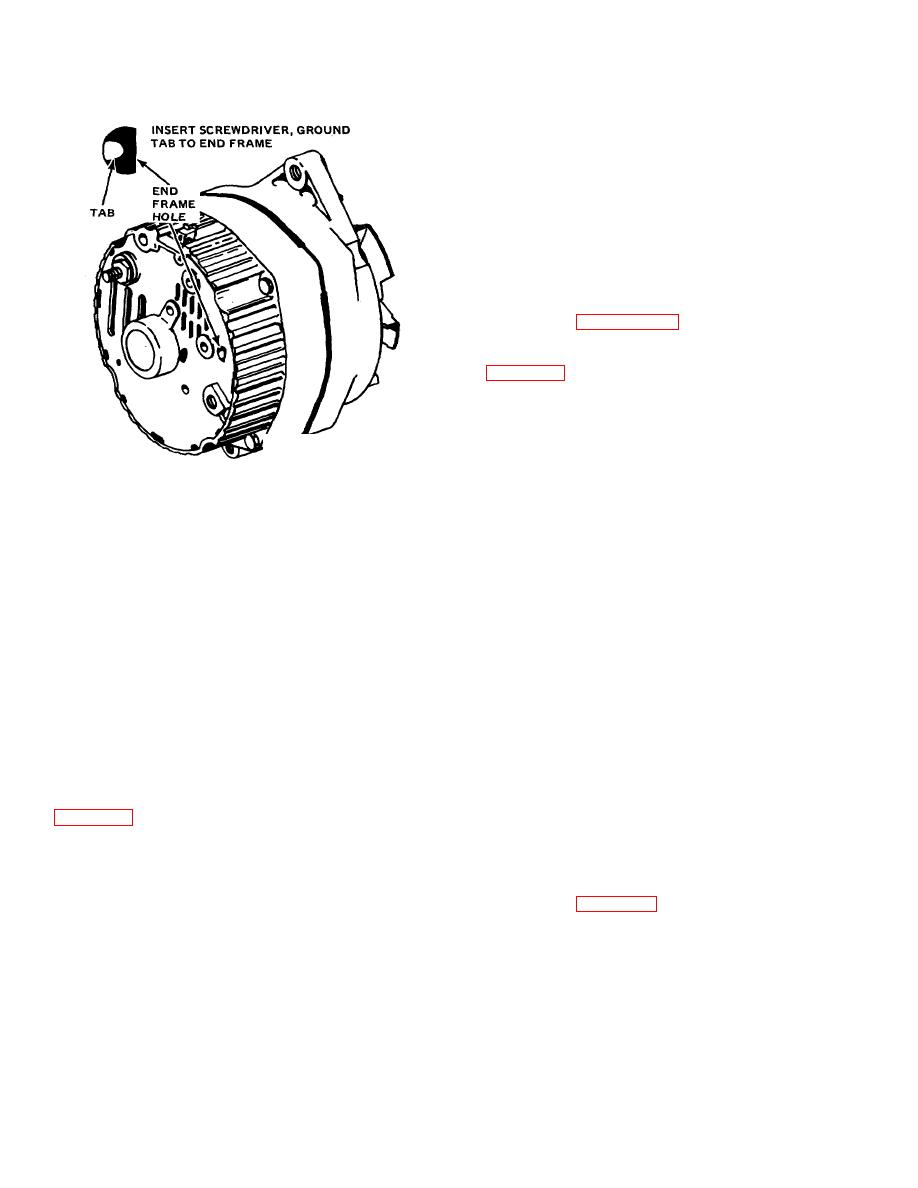

TS5-4310-354-14/7-8

Figure 7-8. Grounding alternator field winding.

Section II. STARTING MOTOR ASSEMBLY

7-3. General. The starting motor assembly converts

NOTE

electrical energy from the battery into mechanical energy

to crank the engine for starting. A solenoid is mounted

Before disassembly, the starting

on the outside of the frame with the solenoid plunger and

motor assembly should be tested to

pinion shaft mechanism totally enclosed. The drive

determine the extent of disassembly

assembly is an overrunning clutch type which assures

necessary and possible defects to

complete drive engagement before the motor begins to

look for at disassembly.

rotate. When the engine starts, the clutch releases and

allows the pinion to turn faster than the armature shaft

b. Testing Before Disassembly. Check the pinion

until the start switch is released and the return spring

for freedom of operation by turning it on the screw shaft.

action retracts the pinion from the flywheel ring gear.

Check armature for freedom of rotation by prying the

pinion with a screwdriver.

Tight bearings, a bent

armature shaft, or a loose pole shoe screw will cause the

7-4. Starting Motor Assembly.

armature to bind. If the armature does not turn freely,

a. Removal. Remove the starting motor assembly

the starting motor should be disassembled and

inspected. If the armature does rotate freely, the starting

motor assembly should be given a no-load test before

disassembly as follows:

(1) Make a no-load test setup as shown in

battery and a switch in open position at

setup.

7-8