TM 5-4310-354-14

2. On all piston rings that have the

groove cut on the inside

diameter of the ring, place the

undercut or groove towards the

top of the piston. See figure

(7) Inspect the crankshaft for any rough or

scored marks that might damage the

connecting rod bearing.

If any rough

marks are found, polish the shaft with an

oil stone, very fine emery cloth, or crocus

cloth. Clean the shaft thoroughly after

polishing.

NOTE

The cylinder number is stamped on

the connecting rods and caps on the

camshaft side and to the front of the

TS 5-4310-354-14/7-58

engine.

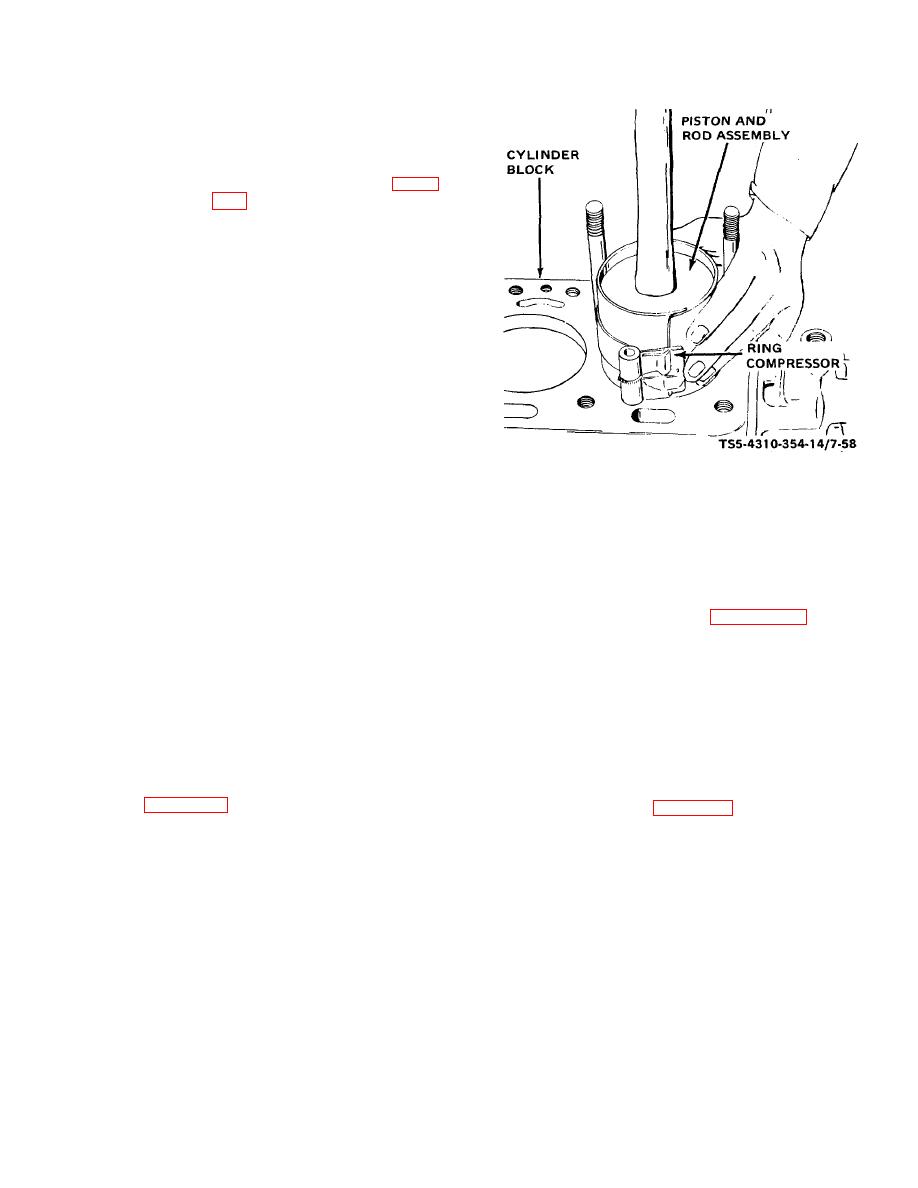

Figure 7-58. Piston installation.

(8) Select the proper piston and connecting

rod assembly for the first cylinder bore

(10) Install the bearings and connect the

and turn the crankshaft so that the

connecting rod to the crankshaft as

connecting rod journal for that cylinder is

follows:

in the lowered position. Apply a coat of

lubricating oil to the cylinder bores,

(a) With the piston entirely in the

pistons, rings, piston pin, and crankshaft

cylinder bore, insert the upper

journal.

bearing (4, figure 7-55) in the

connecting rod (11). Pull the piston

(9) Use a ring compressor to compress the

and rod assembly down until the

piston rings to facilitate installation of the

upper rod bearing (4) seats firmly on

piston and rod assemblies.

With the

the crankshaft journal.

connecting rod bearing cap and bearings

removed from the connecting rod, insert

(b) To check crankshaft journal-to-

the piston from the top of the cylinder

bearing shell clearance, place a

block. Use a hammer handle or block of

piece of plastic gauge material the

wood against the top of the piston to push

full width of the lower bearing (3)

the piston into the cylinder bore. See

about 1/4-inch (6.35 mm) off center

(see figure 7-59). Rotate the

rod is in line with the crankshaft journal

and will not score the journal.

7-63