TM 5-4310-354-14

(4) Inspect the thrust plate (2) for worn or

scored thrust surfaces and distortion.

(5) Inspect the camshaft gear for worn,

cracked, or broken teeth, and worn

keyway. Replace a damaged gear.

(6) Check the valve tappets for wear and

replace any that exceed 0.005 inch (0.127

mm) clearance in the cylinder block bore.

c. Reassembly and Installation.

(1) Insert the valve tappets in their respective

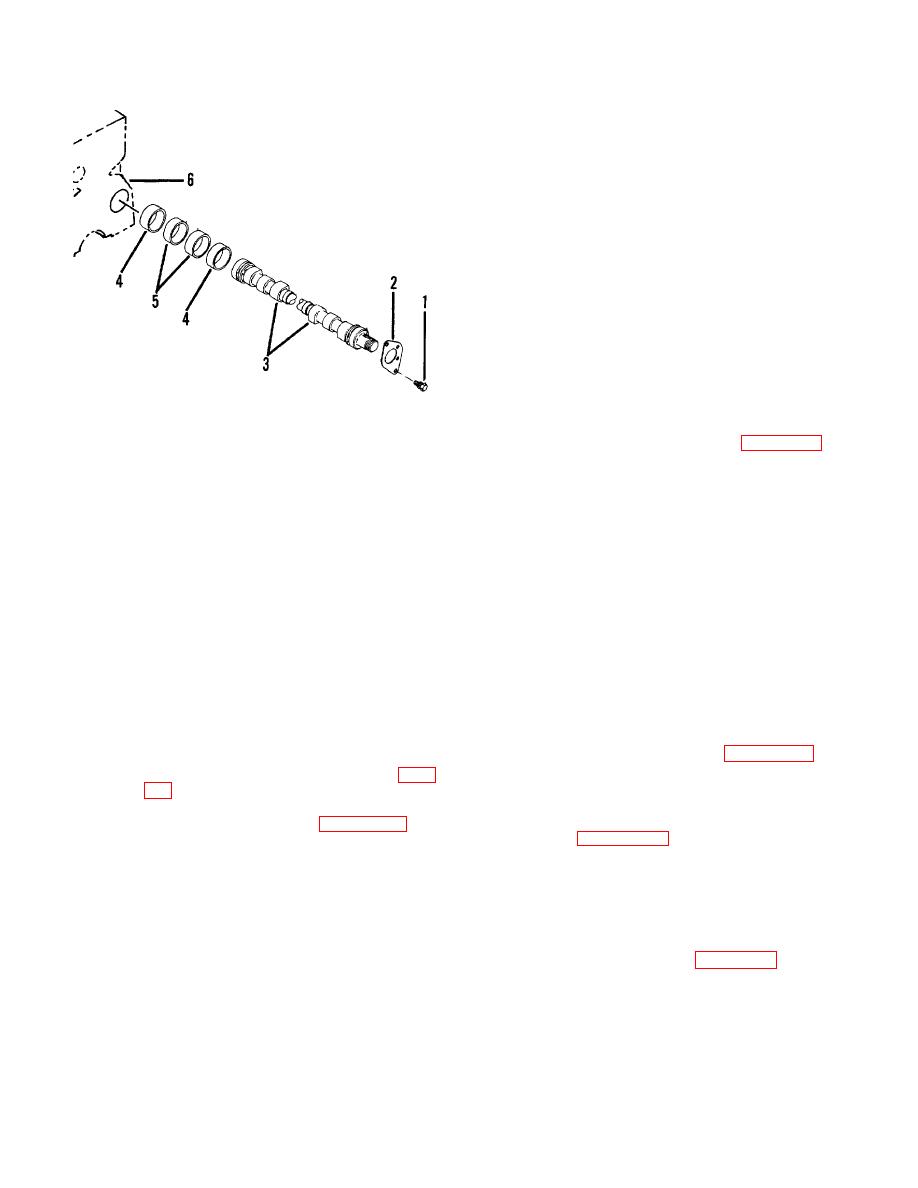

1.

Bolt and washer (2)

holes in the cylinder block. Make certain

2.

Thrust plate

that they are in the raised position in the

3.

Camshaft

block before installing the camshaft.

4.

Front and rear bearing (2)

5.

Intermediate bearing (2)

(2) Install the front, rear, and intermediate

TS 5-4310-354-14/7-53

6.

camshaft bearings (4, 5, figure 7-53) in the

cylinder block.

Replacement camshaft

Figure 7-53. Camshaft and bearings,

bearings are precision cut and no line

removal and installation.

reaming is required.

When installing,

make sure the oil holes in the bearings are

(9) If it is necessary to remove the camshaft

aligned with the oil holes in the drilled

gear from the camshaft, remove the nut,

passageways in the cylinder block. Tap

place the shaft in an arbor press and, with

bearings into place with a bearing driver.

suitable supports under the gear, press

the shaft out of the gear. Remove key

(3) If the camshaft gear was removed from

from camshaft and remove the camshaft

the camshaft (3), place the thrust plate (2)

thrust plate.

on the camshaft (3) and press the gear

onto the camshaft with key in place.

(10) After the camshaft has been removed

Secure with nut. Make certain all tappets

from the engine, the valve tappets can be

are in the raised position. Carefully insert

removed from the underside of the block,

the assembled camshaft into the cylinder

as necessary.

block, aligning the timing marks on the

camshaft gear with the timing marks on

b. Cleaning, Inspection, and Repair.

the crankshaft gear (figure 7-50). This

ensures correct timing of the valves.

(1) Clean all parts in accordance with para

5-7.f.

(4) Secure the thrust plate to the cylinder

block with two bolt and washer assemblies

(2) Inspect the camshaft (3, figure 7-53) for

scored or worn cams and bearing

surfaces, damaged oil pump gear, threads

play. Normal end play is 0.005 to 0.008

or keyway, or worn thrust surfaces.

inch (0.127 to 0.203 mm) and shall not

Replace camshaft (3) if it has scuffed,

exceed 0.012 inch (0.3048 mm).

To

scored, or cracked valve cams. Replace

decrease end play, use a draw file to

camshaft if any bearing journal diameter is

remove a small amount of metal from the

worn to less than 2.051 inches (52.0954

camshaft gear hub on which the thrust

mm).

plate rides. See figure 7-54. To increase

end play, add a shim between the

(3) Inspect the bearings (4, 5) for scored or

camshaft gear hub and the camshaft

worn bores, cracks, or scored faces.

bearing, or, using a piece of very fine

Replace worn or damaged bearings. The

emery cloth on a surface plate, polish the

maximum allowable clearance between

thrust plate to the desired thickness.

camshaft journal and bearing bore is

Check the backlash of the camshaft gear

0.006 inch (0.1524 mm).

to the crankshaft gear.

7-59