TM 5-4310-354-14

(0.0127 mm) and in connecting rod is

line with the piston pin holes. Then, slide

0.0012 inch (0.0305 mm).

the piston pin (9) in place. To facilitate

assembly, heat the piston (10) in boiling

(7) Inspect the pistons (10) for damaged ring

water for a few minutes, but do not heat

grooves, scoring, or cracks. Remove light

the piston pin (9). Install the pin retaining

scoring with fine emery cloth. Replace

rings (8).

piston if damaged beyond repair.

(6) Install the piston rings (5, 6, 7) on the

c. Reassembly and Installation.

piston (10) as follows:

(a) Install the rings on the piston with an

NOTE

expander tool. To avoid breaking or

overstressing the rings, do not

All parts should be at room

spread them any more than

temperature

to

ensure

proper

necessary to slip them over the

dimensional tolerances during piston

piston.

and ring fitting.

(1) Check the fit of the piston without rings in

(b) When installing the piston rings,

the cylinder bore with a feeler 0.005 x -

stagger the positions of the ring

inch (0.127 x 12.7 mm) between the

gaps around the piston to minimize

piston and bore. Use a spring scale to

compression loss. No two ring gaps

determine the force required to withdraw

may be in line.

the feeler stock. A newly honed bore with

a new piston should require between 5

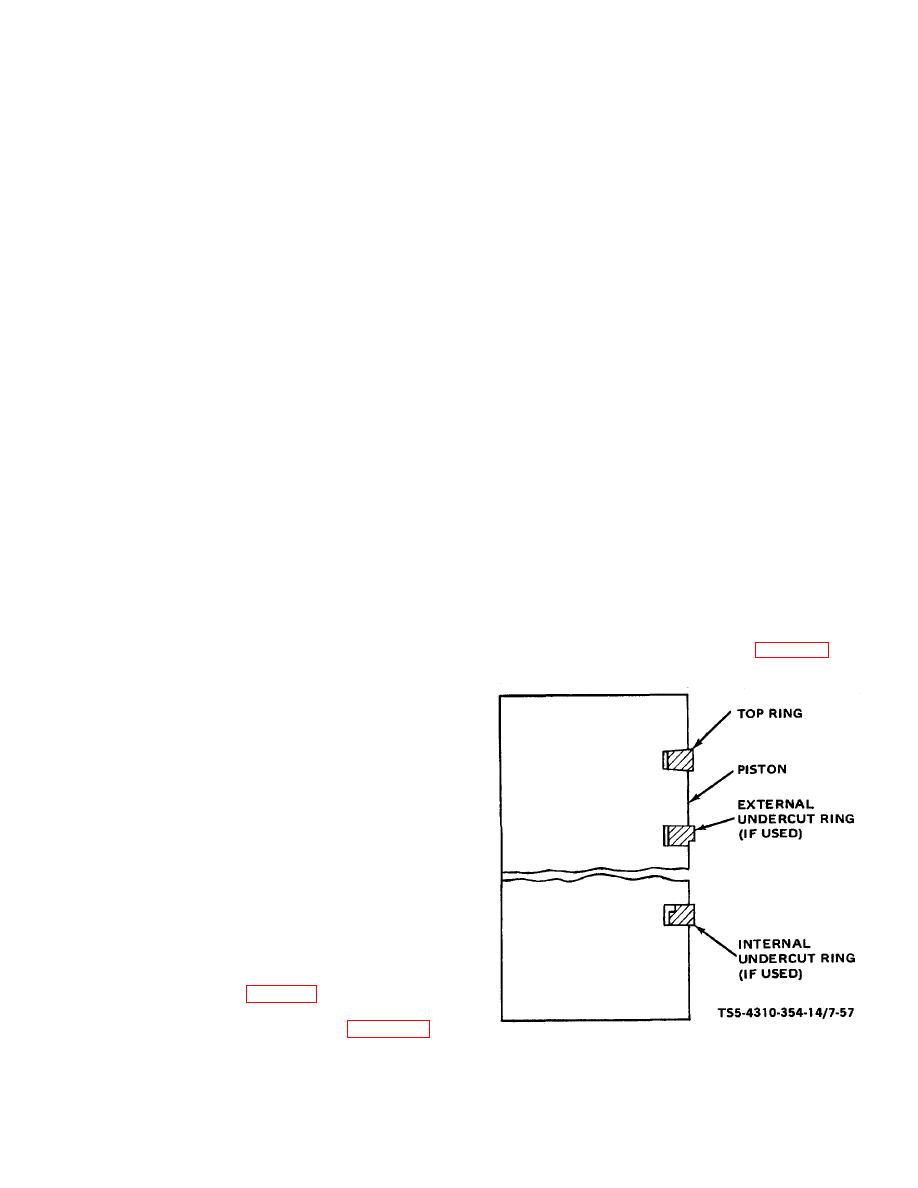

(c) When installing piston rings with

and 8 pounds (2.27 and 3.63 kilograms)

undercut grooves, note the following

pull. A used piston in a honed bore must

instructions:

require a minimum of 5 pounds (2.27

kilograms) of pull. If any binding occurs,

1. On all piston rings that have the

remove the piston and examine the piston

groove on the outside diameter

and cylinder wall for burrs. Remove burrs

of the ring, place the undercut or

with a fine hone (a flat one is preferable)

groove towards the bottom of

before proceeding with the clearance

the piston. See figure 7-57.

check. If a new standard piston is to be

installed, specify size by the letter A, B, C,

or D stamped on top of the piston.

(2) All new piston rings must be installed

whenever a piston is removed, regardless

of whether a new or used piston is

installed.

(3) Insert one ring at a time inside of the

cylinder bore, far enough down to be

within the normal area of the ring travel.

Use a piston to push down the ring to be

sure it is parallel with the top of the

cylinder bore. Measure the ring gap with

a feeler gauge. All ring gaps shall be

0.010 to 0.020 inch (0.254 to 0.508 mm).

(4) Check the ring clearance in the piston ring

grooves. (See table 5-2.)

TS 5-4310-354-14/7-57

(5) Assemble each piston (10, figure 7-55)

and connecting rod assembly (11) by

Figure 7-57. Piston ring installation.

placing the upper end of the connecting

rod between the piston pin bosses and in

7-62