TM 5-4310-354-14

The backlash must be 0.0015 to 0.0025

inch (0.0381 to 0.0635 mm).

(5) Install the pushrods in the cylinder block.

Install the rocker arm assembly and

cylinder head cover (para 7-12).

(6) Install the gear housing cover (figure

(7) Install the oil pump assembly (para 7-16)

and oil pan (para 7-15).

(8) Install drive belt and fan (figure 7-33).

(9) Install the engine (para 5-12 and figure

-

5 7) and adjust the valve clearance (figure

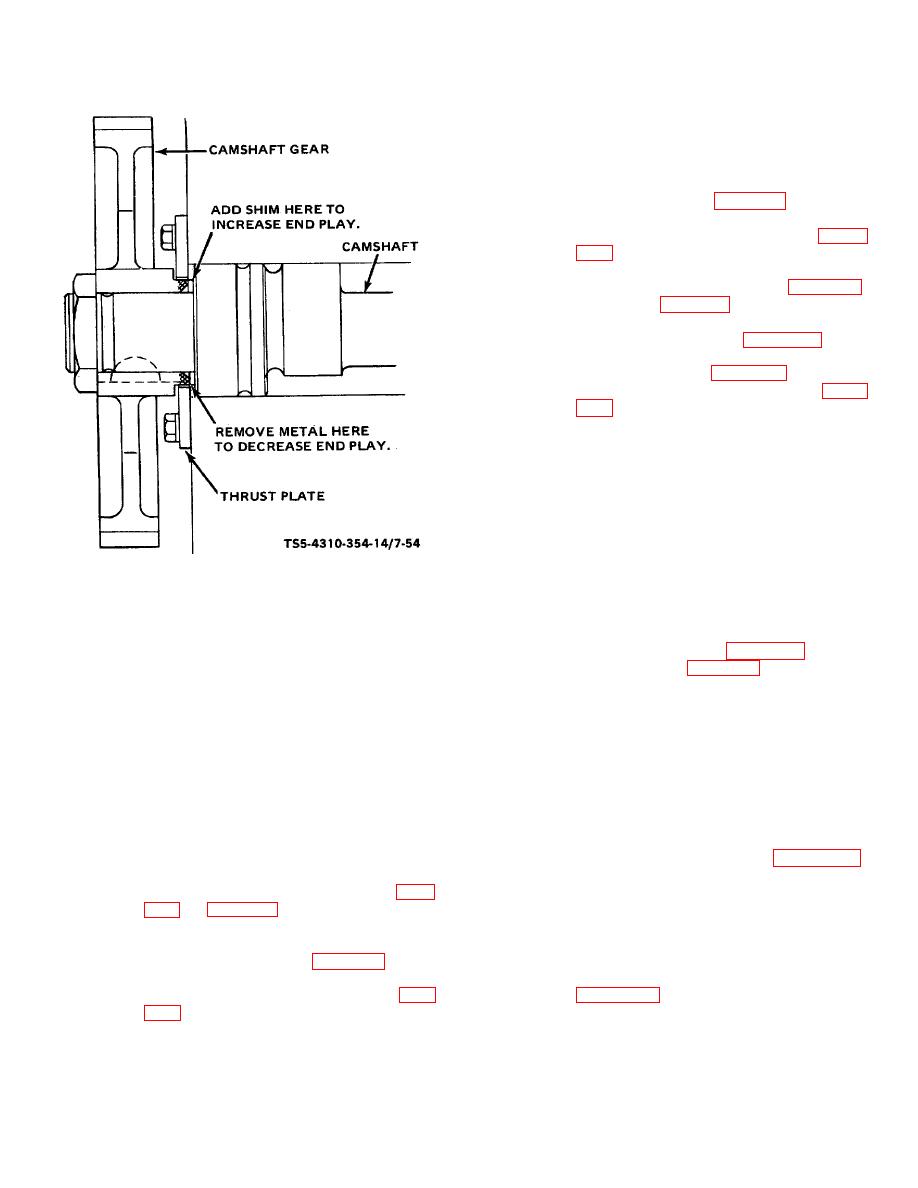

TS 5-4310-354-14/7-54

Figure 7-54. Adjusting camshaft end play.

Section XI. PISTONS. PISTON RINGS, AND CONNECTING ROD ASSEMBLIES

(4) Remove the oil pan (para 7-15) and oil

no saw slots or splits in the skirt. Piston ring sets consist

pump assembly (para 7-16).

of compression rings and oil regulating rings. The piston

pin is the full floating type, able to rotate in the piston as

(5) Carefully scrape the carbon deposits from

well as in the connecting rod bushing. The connecting

the top of each cylinder bore so that the

rods are heavy alloy steel forgings with precision-type

pistons can be removed without damage

bearings for the crankshaft and bronze bushings for the

to the rings.

On cylinder bores with

piston pins.

excessive wear, it may be necessary to

use a ridge reamer.

7-24. Pistons, Piston Rings, and Connecting Rod

(6) Crank the engine so that the No. 1 piston

Assemblies.

connecting rod caps can be removed.

a. Removal and Disassembly.

Remove the cap bolts (1, figure 7-55),

connecting rod cap (2), and lower bearing

(1) Remove the engine from the unit (para

(3). Be sure to keep the connecting rod

(11), cap (2), and bearings (3, 4) for each

piston together. Do not mix parts. With a

(2) Remove cylinder head cover, rocker arm

block of wood or hammer handle, carefully

assembly, and pushrods (para 7-12).

push the piston and rod assembly out

through top of the cylinder block. (See

(3) Remove the cylinder head assembly (para

piston are removed from the cylinder

block, reassemble the connecting

7-60