TM 5-4310-360-14

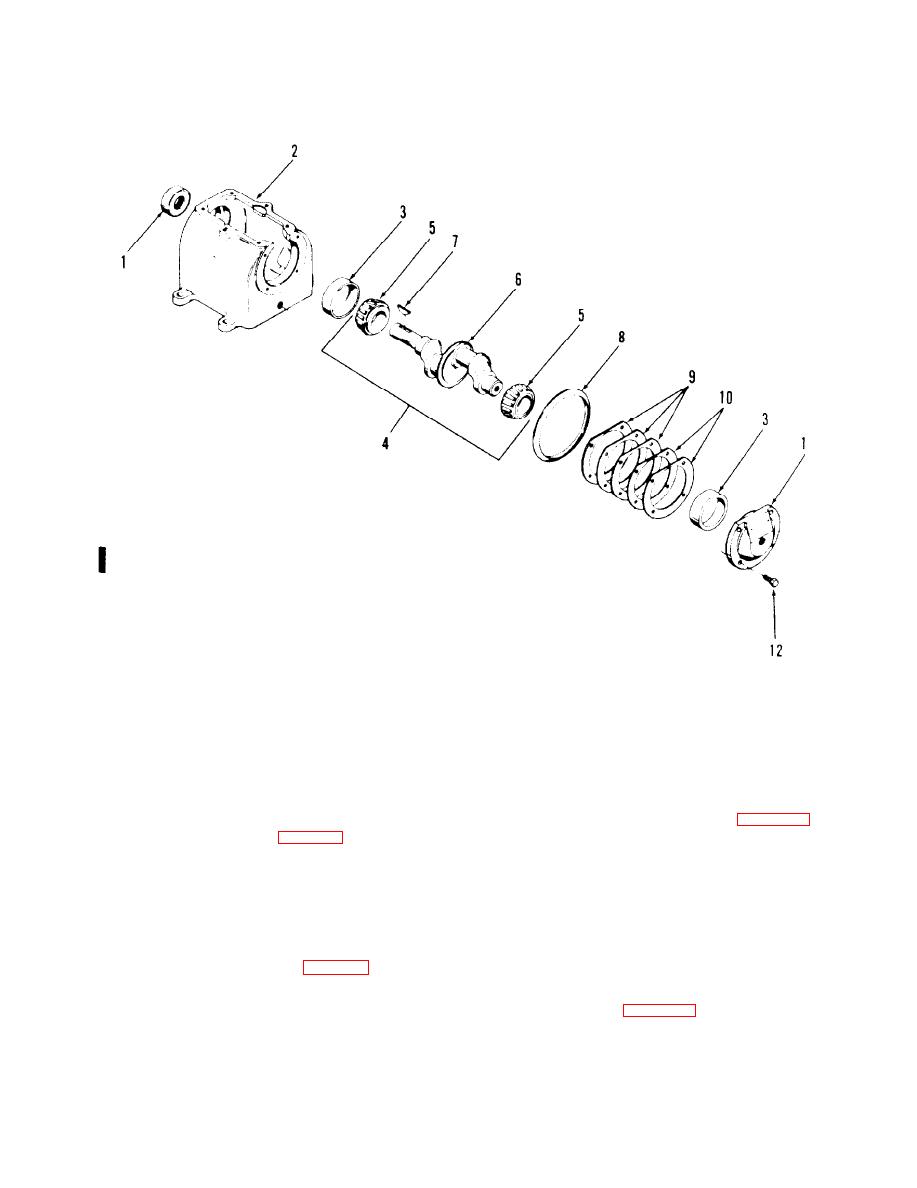

6-2. Pistons, Rings, Connecting Rods, Cylinder

Block, Crankshaft and Crankcase - continued.

1.

Oil seal

2.

Crankcase

Bearing cup

3.

4.

Crankshaft assembly

5.

Bearing cone (2)

6.

Crankshaft

7.

Key, Woodruff

8.

Oil feeler ring

9.

End cover gasket (3)

10.

End cover gasket (2)

11.

End cover

12.

Screw, cap, hex head (4)

Figure 6-2. Crankshaft and crankcase.

Reassembly and Installation.

c.

(3)

Measure the clearance between small

end of connecting rod and wrist pin.

Crankshaft crankcase. Before assem

(1)

Also measure the clearance between

bling, the crankshaft (6, figure 6-2)

large end of connecting rod and crank-

must be fitted to the crankcase (2).

shaft. Refer to table 1-1 for allowable

Install cover (11), gaskets (9 and 10)

clearances.

and secure with end cover screws (12)

evenly. End cover gaskets (9 and 10)

serve as shims and are furnished in

(41

Examine crankshaft and pistons for

two thicknesses. The proper combina-

wear, scuffing, scoring, etc., and

tion must be selected so crankshaft (6)

replace parts damaged. If parts exceed

can be spun in the bearings without

clearance listed in table 1-1, replace

end play. Refer to table 1-2 for end

them.

play allowance. Also see that oil feed

ring (8, figure 6-2) rotates freely on

the crankcase. Remove crankshaft

from the crankcase anti hold long end

(5)

inspect tapered roller bearing for

in a vise using soft jaws to prevent

rough, pitted, or scored surfaces

damage.

Replace a defective bearing.

6-3

Change 1