TM 5-4310-368-14

Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES

4-11.

ORGANIZATIONAL PREVENTIVE MAINTENANCE CHECKS AND SERVICES

Refer to Table 4-1 for preventive maintenance checks pertaining to organizational maintenance.

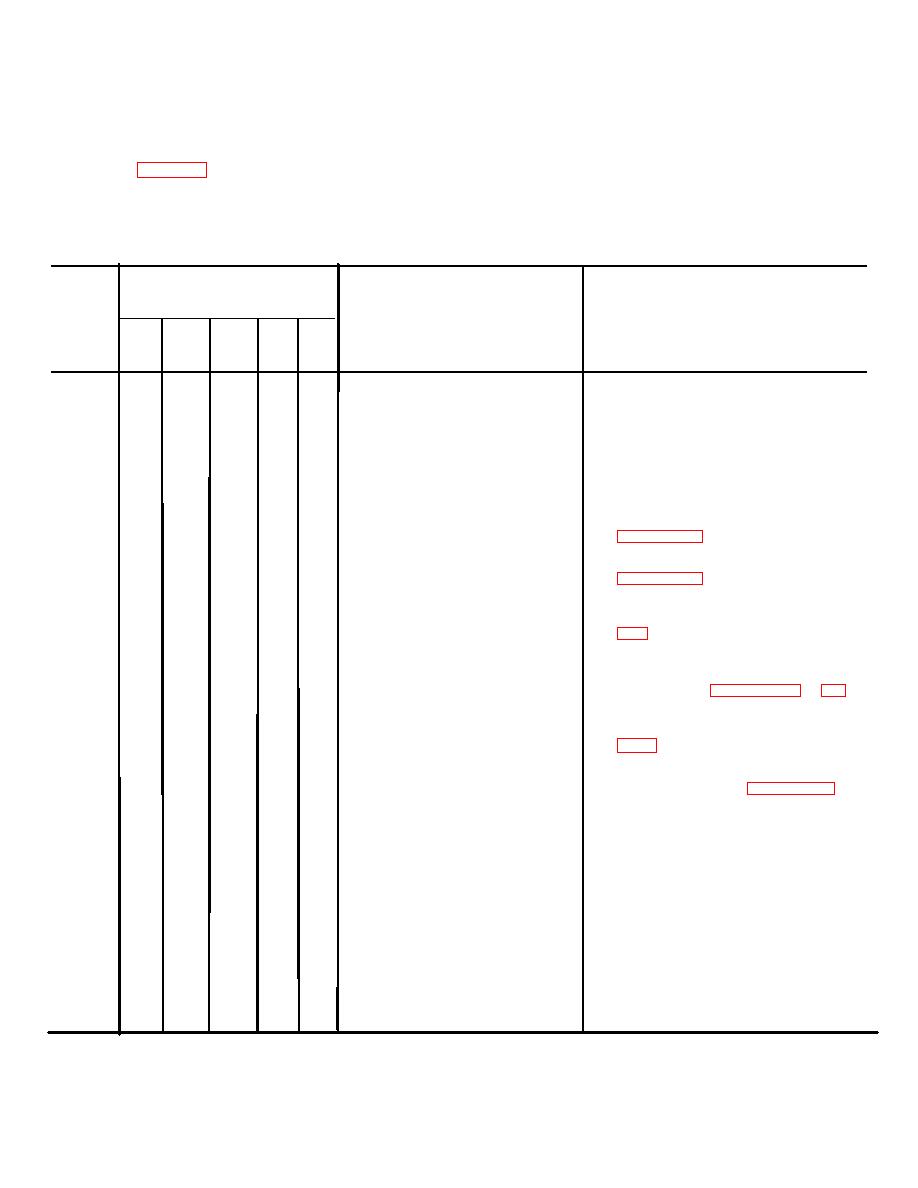

Table 4-1. Organizational Preventive Checks and Services

D - Daily

W - Weekly

M - Monthly

Q - Quarterly

H - Interval in Hours

INTERVAL

Item To Be

ITEM

Procedures

Inspected

NO.

H

D

W

M

Q

MIL-L-2104 ( - 10 to +130 )

1

50

Engine Oil Change

F

F

2

100

Engine Oil Filter Change

MIL-L-26087 ( - 10 to +125 )

3

250

Compressor Oil Change

F

F

4

250

Compressor Oil

Filter Change

5

X

Compressor V-Belts

Inspect belts for wear, fraying, peeling,

cracking and tension. Adjust belt ten sion if

deflection exceeds 1/2" (13 MM). See

6

X

Air Cleaner

Check air cleaner element. Replace if dirty. See

paragraph 4-34 for replacement.

7

X

Dehydrator Cartridges

Check hourmeter and instruction plate.

Replace cartridges as required. See paragraph

8

X

Meters and Gages

Inspect for damaged faces, pointers, lenses,

liquid fill leaks and proper operation. Replace

as required. See paragraphs 4-45 and 4-47 for

replacement. Liquid level in pressure gages

should be halfway to full, fill gages with glycerin

if level is below middle of gage. See paragraph

4-47A for service.

9

X

Air Hose and Fittings

Inspect for wear, cracks, cuts and damage.

Replace as required. See paragraph 4-14.

10

X

Switches, Controls

Inspect for operation and damage.

and Valves

Replace as required.

Change 1

4-6