TM 5-4310-369-14

(d) Lift-off head and head gasket.

b. Cleaning and Inspection.

(4) Mark the top of each piston (with cylinder

number and position within cylinder) so that each piston

can be reinstalled in the right cylinder and in the same

Drycleaning solvent, P-D-680, used to clean parts

position within the cylinder.

is potentially dangerous to personnel and property.

(5) Remove hand hole plate (bottom of crank-

Avoid repeated and prolonged skin contact. Do

case) (38).

not use near open flame or excessive heat. Flash

(a) Remove bolts (39).

point of solvent is 100F (38C).

(b) Remove plate (38).

(1) Clean all parts with cleaning solvent, item 5,

(c) Remove gasket (40).

App. D, and dry thoroughly.

(6) Remove pistons.

(2) Inspect all parts for cracks, breaks, and other

NOTE

damage. Replace a defective part.

(3) Discard and replace cylinder head gasket.

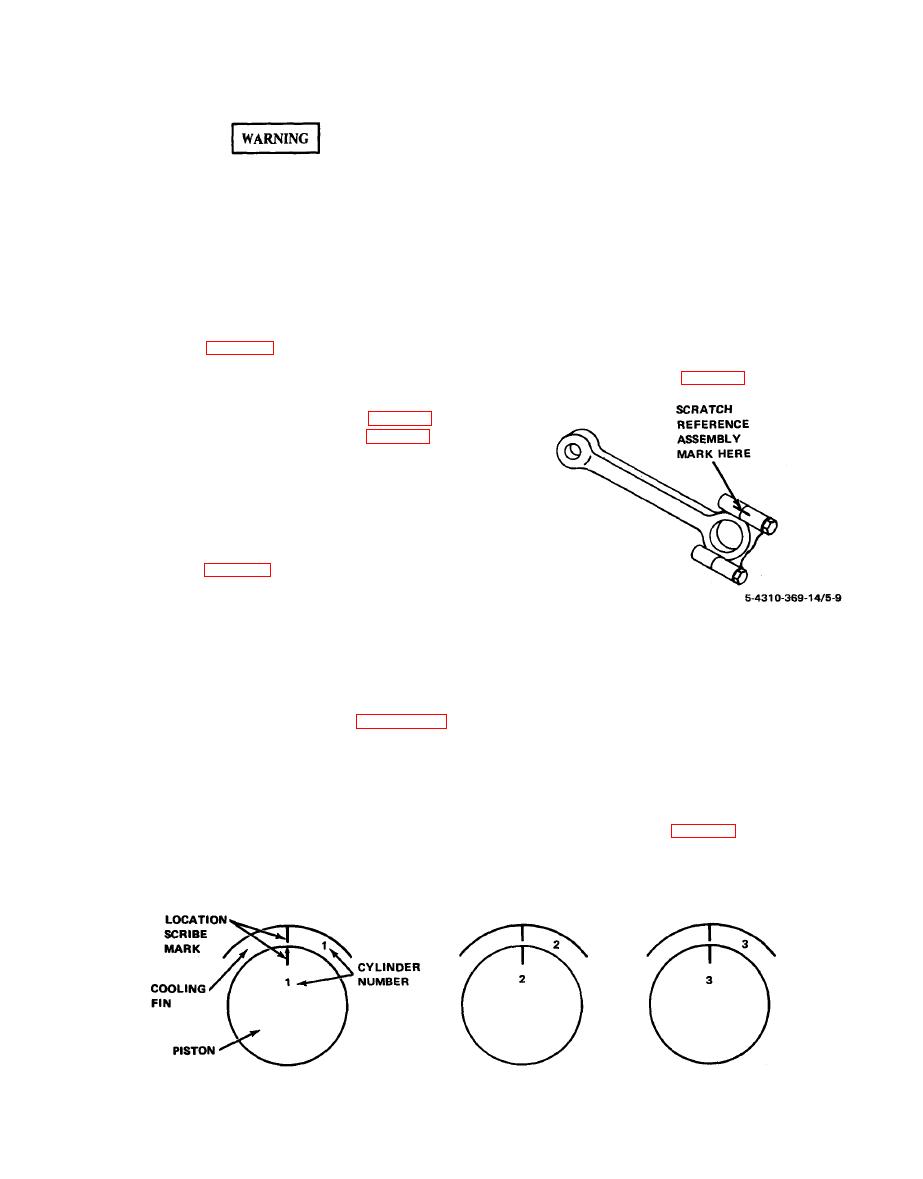

Each connecting rod and associated rod end-cap

c. Installation. (Figure 5-5).

must be kept together and in the same relation-

(1) Install new cylinder head gasket (17).

ship as when removed. (See figure 5-9).

(2) Install cylinder head (15).

(3) Install cylinder head bolts (16).

(6) Install interstage safety valve (59).

sure head.

(8) Attach intercooler tube (7).

Crankshaft and Crankcase

a. Disassembly (figure 5-5).

NOTE

Scribe reference marks on cylinder head/cylinders

and on cylinders/block.

(a) Turn crankshaft to expose rod end-caps at

bottom of crankcase.

(b) Remove high pressure cylinder rod end-cap

4-12a), place on suitable workbench and drain oil. Remove

first by removing bolts (42).

nipple (3) from compressor.

(c) Remove bolts (29) from cylinder and remove

cylinder piston assembly from crankcase.

NOTE

(d) Pull piston from cylinder.

Keep parts together as an assembly.

NOTE

(3) Remove high pressure head:

Immediately replace rod end-cap on connecting

(a) Disconnect intercooler tube.

rod using assembly marks (figure 5-9).

(b) Disconnect compressor discharge hose from

high pressure head.

compressor by repeating steps (a) and (b).

(c) Remove head bolts.