TM 5-4310-375-14

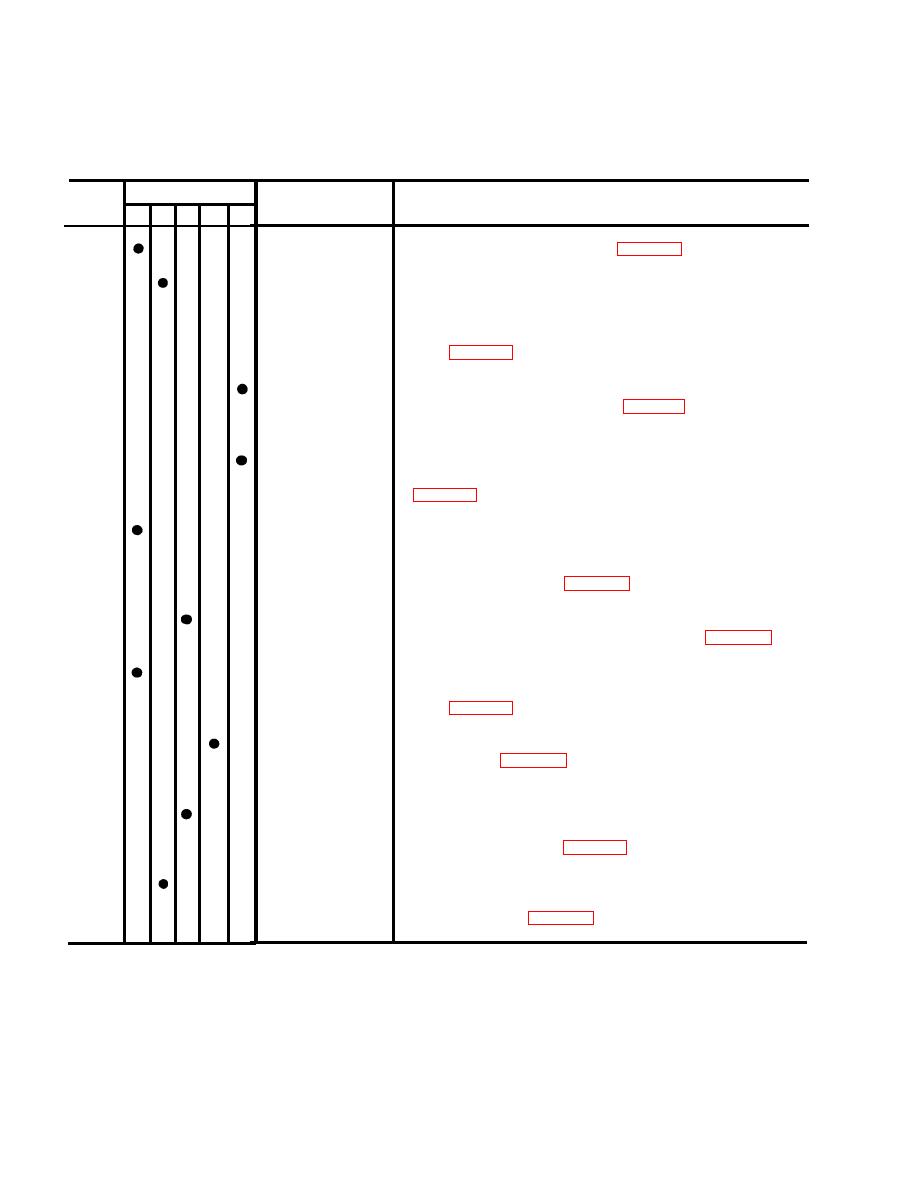

Table 4-2. Organizational Preventive Maintenance Checks and Services

Hours

H

-

-

Semiannually

Monthly

S

M

-

A

-

Annually

Quarterly

Q

-

ITEM TO BE

INTERVAL

ITEM

Q

PROCEDURE

M

AH

INSPECTED

S

NO.

V-Belts

Adjust drive belt tension as shown in figure 2-3.

1.

Inspect the pressure switch for physical damage, tightness of

Pressure switch

2.

wiring lead connections and function while operating. Cut-in

pressure is 175 psi 10 psi (1 2.3 kgs/cm2 0.70 kgs/cm2) and

cut-out is 200 psi +0 -10 psi (14.1 kgs/cm2 +0, -0.70 kgs/cm2).

Refer to para 4-17.

Every 1500 hours check the air compressor first and second stage

Compressor first

3.

valves for wear and damage. Refer to para 4-19.

and second stage

valves.

Every 1500 hours, when item 3 above is performed, clean the

4.

Intercooler and

intercooler and aftercooler and inspect for any damage. Refer

aftercooler

to para 4-20.

When adjusting drive belt tension (Item 1. above), inspect flywheel

Flywheel

5.

for chipping or cracks on drive belt grooves and air circulating

ribs. Inspect for tightness on compressor crankshaft. Replace a

damaged flywheel. Refer to para 4-21.

Inspect check valve for any physical damage and air flow direction

6.

Check valve

operation. Replace a defective check valve. Refer to para 4-23.

Inspect pressure gauge for broken face and proper operation while

7.

Pressure gauge

pressure is in air receiver tank. Replace a defective pressure gauge.

Refer to para 4-24.

Inspect air receiver tank for any dents, rusting, or other physical

Air receiver tank

8.

damage. Refer to para 4-26. If replacement is necessary, notify

Direct Support.

When notified by operator/crew of defective inflator gauge or

Inflator gauge and

9.

globe valve, replace. Also, at interval indicated, check for leaks

globe valve

and operation as directed in para 4-27 and 4-29.

At interval indicated, check air service hose for cuts, fraying of

Air service hose

10.

hose cover, and damaged hose end fittings. Replace a damaged

service hose. Refer to para 4-28.

4-6