TM 5-4310-376-14

OPERATING PROCEDURE - Continued

2-5.

c. Operational Checks

In case of malfunction, immediately shut

off compressor by stopping gasoline engine

and notify organizational maintenance per-

sonnel.

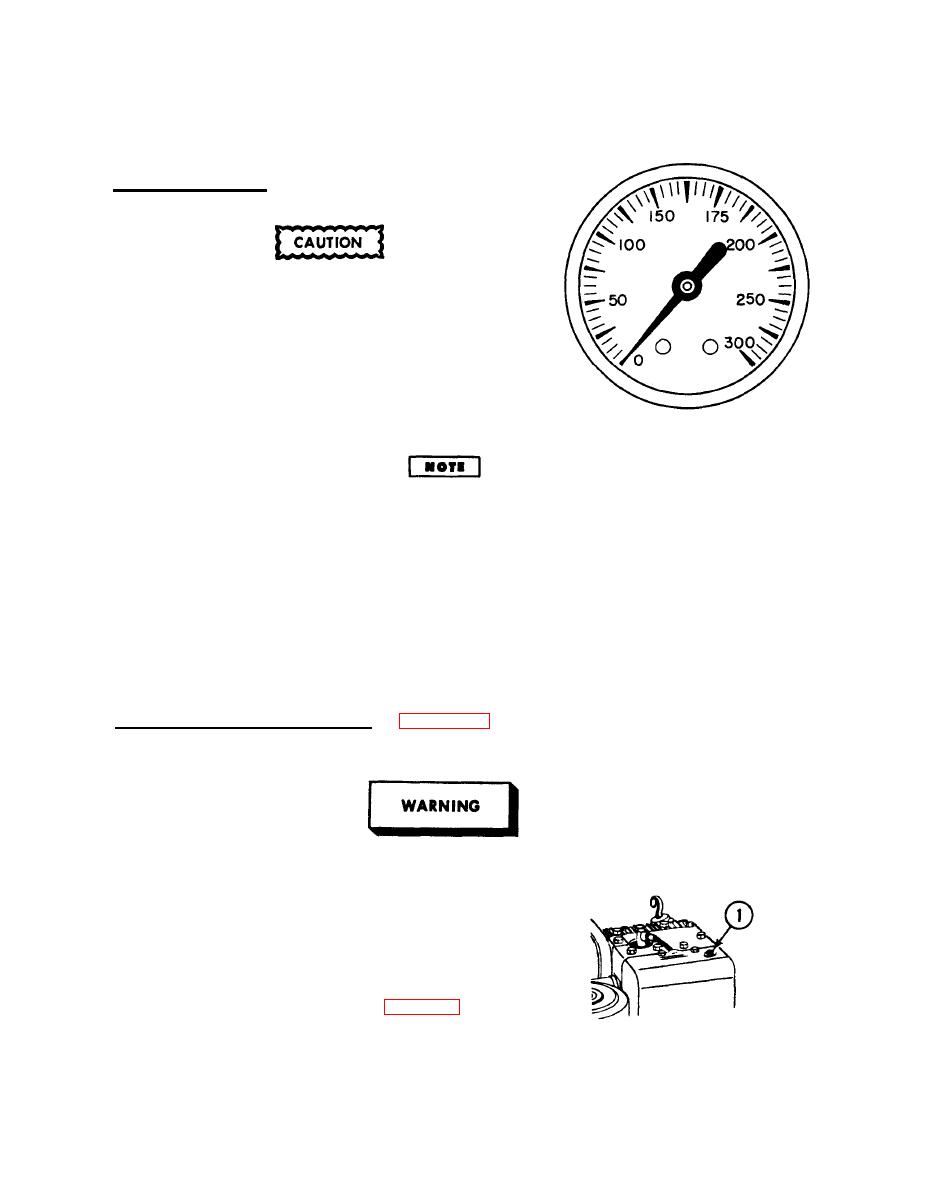

(1) As compressor operates, air pressure gage will indicate

amount of air in the receiver tank. Check gage frequent-

ly.

When air pressure reaches 200 psi, the unloading control

valve opens and remains open until pressure in the air

tank falls below 175 psi.

(2) As air pressure increases, check for air leaks. Air leaks can be found by listening for

hissing sound which is the air escaping from a loose connection.

(3) Engine will operate normally for about four hours on a full tank of gasoline. Stop engine

and add fuel after about four hours of operation.

d. Operating Instructions on Decals (See figure 2-2).

2-6. STOPPING OPERATION

DO NOT TOUCH hot muffler, cylinders or fins as contact

may cause burns.

(1) Operate ON-OFF switch (1) to OFF position.

(2) Release air pressure from receiver.

(3) Perform AFTER PMCS listed in table 2-1.

2-10