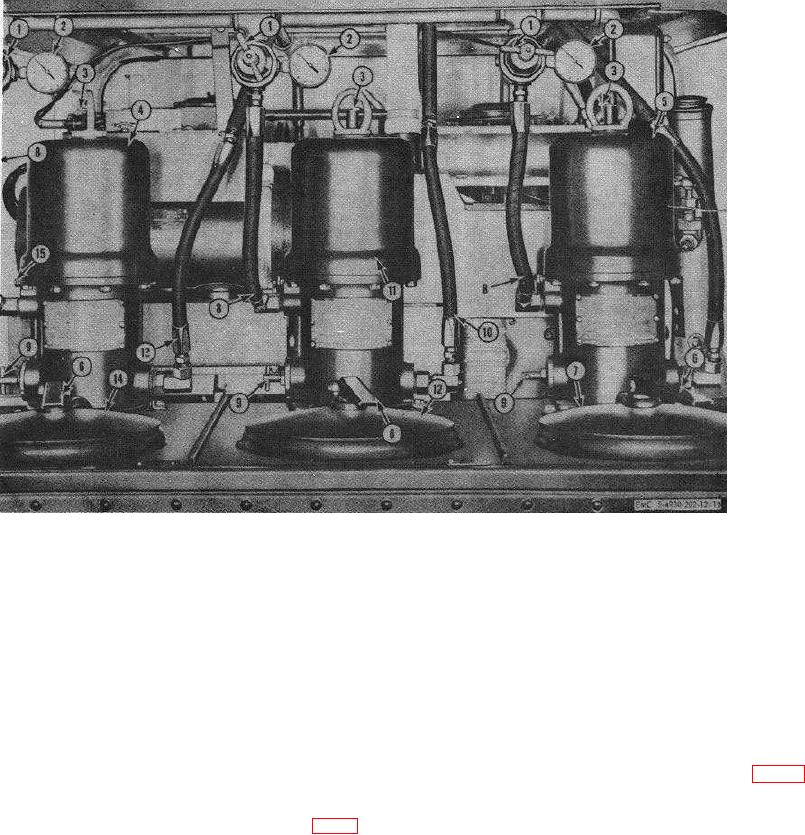

1

Compressor intake muffler

7

Heater slide tray

13

Air receiver safety valve

2

Safety valve

8

Heater control switch

14

Engine exhaust director handle

3

Fuel pump primer lever

9

Reset button

15

Cap screw, 5/16-18 x 1 in. Ig (2 rqr)

4

Thermostat

10

Press-to-test lamp

16

Bracket

5

Heater bleeder valve

11

Center toolbox

17

Quick coupling

6

Heater

12

Air receiver pressure gage

Figure 9. Lubricating unit controls and instruments, compressor side.

excess air pressure from the receiver at a

exhaust gases through a hose to atmosphere outside

predetermined setting of 200 pounds. If for any reason

the unit, when heating of grease and oil is not desired.

the pressure need be released before the excess

pressure point has been reached, grasp the ring located

38. Air Regulators

on the safety stem, and pull upward to open the safety

Air pressure and speed, to the three lubricating

valve and allow the air to escape.

pumps, are controlled by the air regulators (1, fig. 10)

mounted on the air line between the air receiver and the

37. Engine Exhaust Director Handle

lubricant pumps. The exact air pressure to operate the

The engine exhaust director handle (14, fig. 9) is

pumps must be determined by the operator, based upon

used either to direct heat from the engine exhaust into

volume or delivery rate required. To increase air

the lubricant compartment heat chamber, or direct

pressure to pumps turn regulator handle clockwise.

20