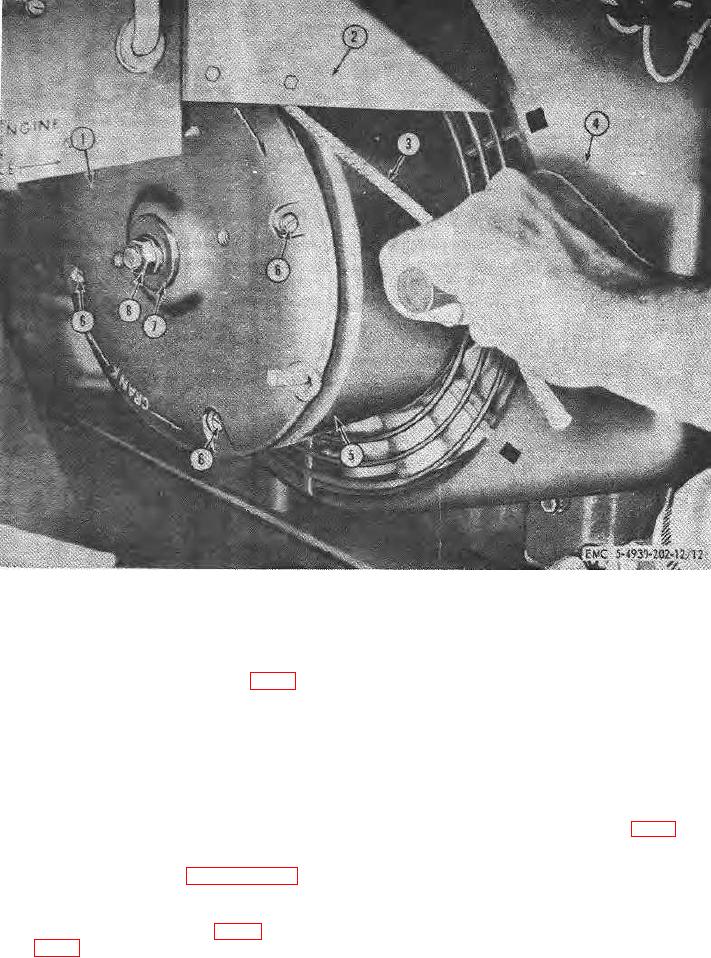

1

Rope sheave

3

Starting rope

5

Blower and hub

7

Flat washer, 7/16, in.

2

Heat deflector

4

Air shroud

6

Screw, 1/4-28 x 7/8, in. Ig (4 rqr)

8

Nut, 7/16-20

Figure 12. Hand starting the engine.

c. Engage the clutch lever (8) by moving it toward

c. Close the master air control valve (2, fig. 8) and

the hose reels.

open air line pressure relief cock (11) and the drain

valve (6) to release the air pressure in the hoses. to all

Note

three pumps and the air reel.

Engage the clutch slowly, allowing

sufficient time for the compressor to

51. Emergency Stopping of Engine

gain speed before fully engaging

In an emergency such as failure of the stop button,

clutch.

stop the engine by pulling the choke control knob out to

the limit of its travel.

d. Close the master air valve (2, fig. 8) and the air

pressure relief cock (11) at the air receiver.

52. Filling Lubricant Tanks

e. Air pressure in the tank will automatically build

a. Start the engine. Refer to paragraphs 48 and

up to 175 pounds. The pressure switch is pre-set to cut

49.

out at 175 pounds pressure, and cut in at 150 pounds

b. Allow the engine to reach proper temperature

pressure.

and check the oil pressure gage (16, fig. 7) and the

f. Allow pressure to build up, until the air

ammeter (1, fig. 6). Proper oil pressure is between 20

and 35 pounds.

24