until the compressor unloads before

wise the heater air does not pass into the

engaging the pumps.

air cleaner.

(2) The contaminated air from the heater is

d. Setting of Dampers. Shift the hot air duct

exhausted by a heater exhaust tube (6,

dampers to direct heat output to heat the lubricant in

fig. 5) to the atmosphere through the roof

lubricant containers. By swinging the tube container hot

of the inclosure.

air damper up to the open position, and engine hot air

damper to the right into the closed position, heater

(3) The engine exhaust director handle (14,

output will be directed to the lubricant containers. A

fig. 9) directs exhaust gases through a

portion of the heat is also directed to the battery

hose to the atmosphere outside the unit,

compartment. There is no need to delay operation until

when heating of grease or oil is not

lubricants become warm since low-temperature

desired.

When the handle is in the

lubricants can be pumped.

vertical position it conducts exhaust gases

into the reservoir under the lubricant

Note

containers for heating of grease and oil.

The heat for the battery box is

automatically controlled by a control

c. Operation of Special Equipment.

switch and butterfly valve, located in

(1) Prior to cold weather operation (minus 25

the temperature control heating tube.

F. to minus 65 F.) shift the engine hot air

A sending unit, located in the rear of

damper (17, fig. 6) to open position by

the battery drawer, is connected to

swinging the control handle up, to direct

the switch by a capillary tube. The

heated air to the lubricant containers. A

portion of the heat is also directed to the

switch automatically opens the

battery compartment.

butterfly valve and admits heat to the

batteries when the air temperature in

(2) Start the heater (par. 62) and direct heat

the box drops to 30. The switch

to the engine air intake for 45 minutes, by

moving the engine hot air damper (17, fig.

closes

the

valve

when

air

6) into open position as described in

temperature in the box reaches 100.

64. Alcohol Dispenser

(3) Close all lubricating unit doors (15, fig. 1)

Use the alcohol dispenser (9, fig. 6) during cold

and louvers (14).

weather operation. The dispenser is used to inject

(4) After the end of the 45-minute warmup

alcohol into the air lines leading to the pumps to prevent

period start the engine (par. 48 or 49) and

condensate freezeup. It is equipped with an 8-ounce

allow the engine to operate for

capacity metal bowl and a handle needle valve which

approximately 10 minutes.

controls the flow of alcohol.

(5) After the engine has operated for 10

minutes, start the compressor and wait

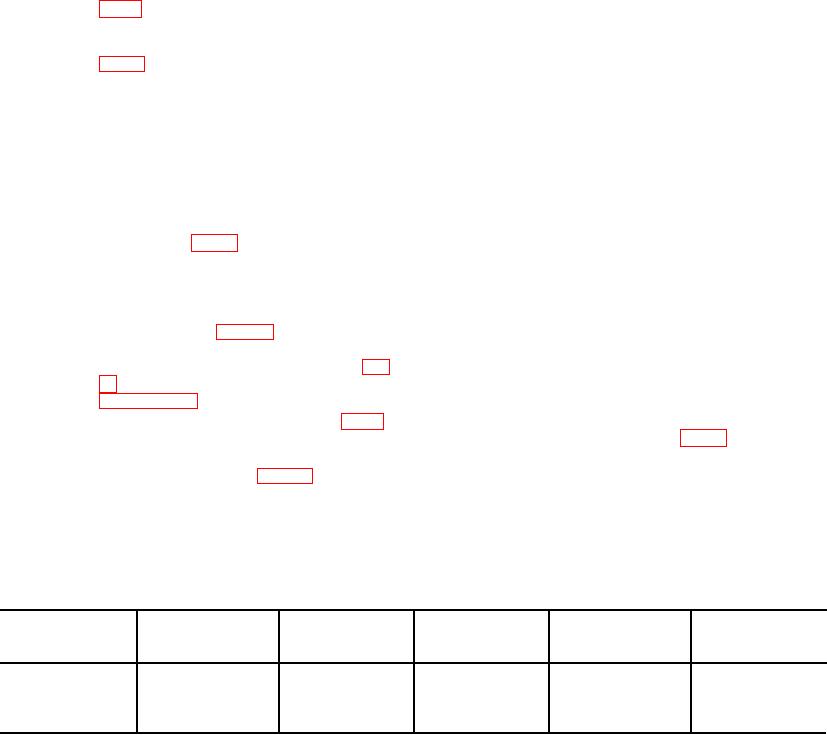

Table IIl. Alcohol Dispenser Valve Setting

40 PSI

Valve

80 PSI

Valve

120 PSI

Valve

to

must be

to

must be

to

must be

pumps

opened

pumps

opened

pumps

opened

1 Pump

2 Turns

1 Pump

11/2 Turns

1 Pump

1 Turn

2 Pumps

11/2 Turns

2 Pumps

11/8 Turns

2 Pumps

3/4 Turn

3 Pumps

1 Turn

3 Pumps

3/4 Turn

3 Pumps

1/2 Turn

Note

For dispensing approximately 9-ounces per hour, operating one, two or three pumps. (With

pumps operating at 24 cycles per minute).

Note

Higher pump operating air pressure and faster cycling will automatically increase the amount of

alcohol dispensed, so that needle valve must be proportionately closed to maintain the desired

flow.

32