(3) Replace connection fittings if threads are

(4) Disconnect the oil line at the oil line elbow

damaged.

(10).

c. Installation.

(5) Remove the oil pressure gage (13) and

bracket (12) from the air shroud (4, fig.

(1) Install the oil pressure gage (13, fig. 31)

on the air shroud (4, fig. 12).

b. Cleaning, Inspection, and Repair.

(2) Connect the oil line (8, fig. 31) to the oil

line elbow (10).

(1) Clean all parts using an approved

cleaning solvent.

(3) Connect the air shroud to its proper

position (par. 122).

(2) Replace the oil pressure gage if the glass

is cracked or broken, and the gage does

(4) Install the right-side engine air shroud

not register properly.

Section IX. COMPRESSING UNIT

130. Description

The compressor on the lubricating unit is a two-stage,

16 cfm unit, with a disk-type valve system. The twin-

cylinder construction gives a higher discharge pressure

with less consumption of power.

A splash-type

lubrication system provides adequate lubrication, even if

the oil level in the reservoir is low. The compressor is

equipped with an automatic pressure control which

unloads the compressor through the auxiliary unloader,

when the tank pressure has reached 175 psi, and allows

compression to resume when the pressure has dropped

to 145 psi. A centrifugal unloader, operating from the

crankshaft automatically opens a valve releasing the

head pressure, when the compressor stops, and closes

when compression is resumed. A trouble control,

connected to the automatic pressure switch unloader

provides automatic reduction of engine speed during the

compressor unload periods.

A manually operated

shutoff cock connected to the inlet of the throttle control

provides manual elimination of this automatic speed

reduction during cold weather operation.

131. Intake Muffler

a. Removal and Disassembly.

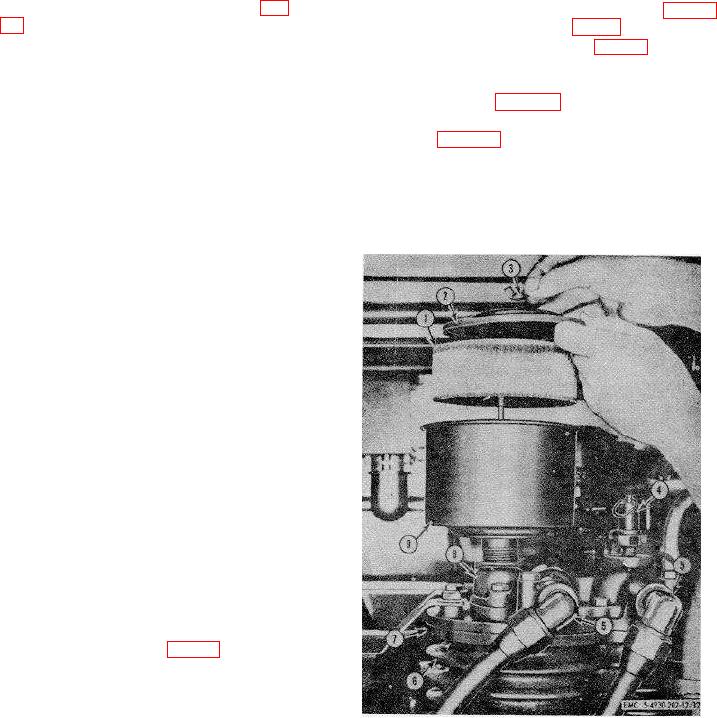

(1) Unscrew the wingnut (3, fig. 32) from top

of the intake muffler.

(2) Remove the cover (2) and the filter

element (1) from the reservoir bowl (9).

(3) Unscrew the reservoir bowl (9) at the

1

Filter element

6

Cylinder

2

Cover

7

Cylinder head

muffler adapter (8).

3

Wingnut

8

Muffler adapter

b. Cleaning, Inspection, and Repair.

4

Safety valve

9

Reservoir bowl

(1) Clean all parts, using an approved

5

Elbow, 3/4 in.

cleaning solvent. Make sure all dirt,

Figure 32. Servicing compressor intake muffler.

grime, and sediment are removed from

the bowl.

70