TM 5-4930-207-34

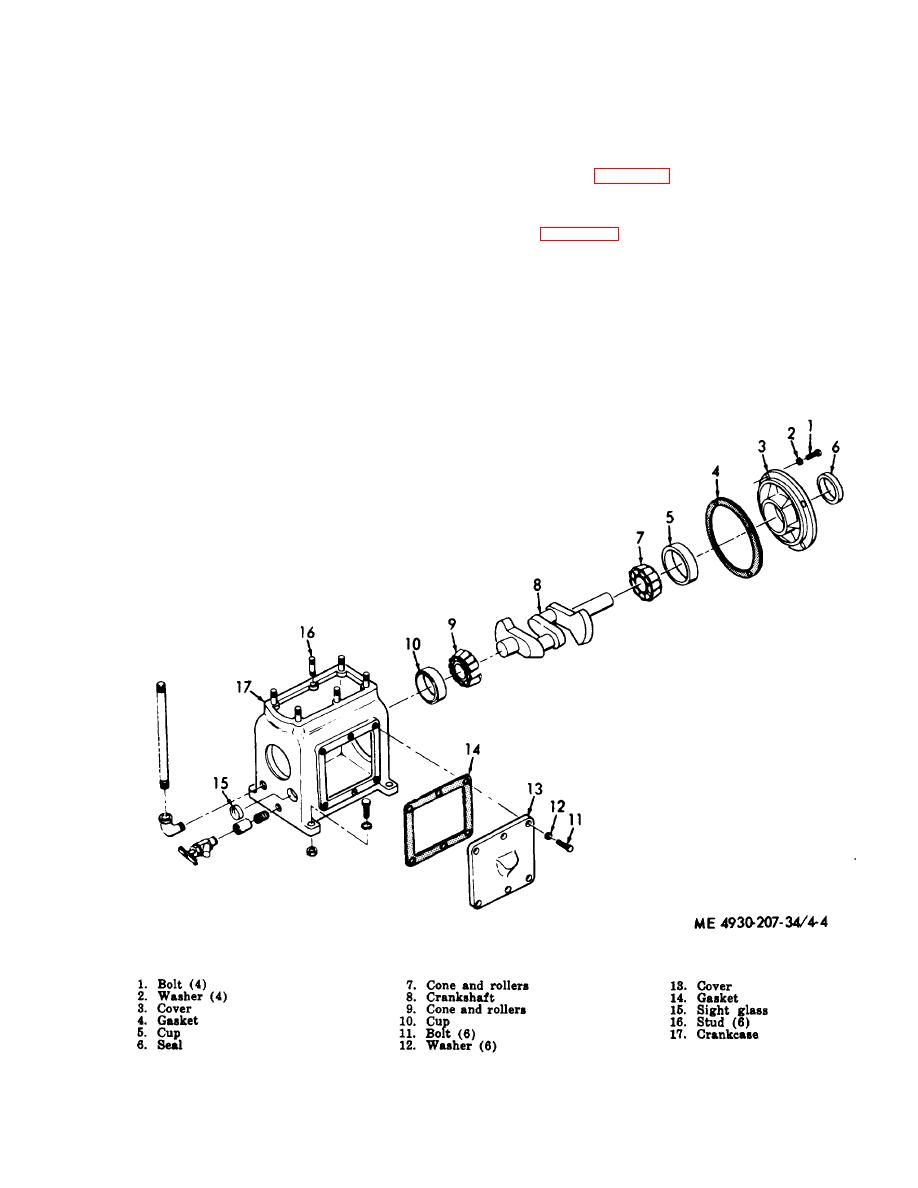

Section IV. CRANKCASE AND CRANKSHAFT

(3) Remove cylinder a n d pistons as in-

4-13. General

strutted in section II. (para 4-6a (1) and (2).

The crankcase is equipped with a sight glass

(4) Remove centrifugal unloader per sec-

which provides maximum protection against dam-

tion III. (para 4-10).

age due to insufficient oil; however the splash-type

b. Disassembly. Disassemble crankcase and

lubrication system provides adequate lubrication,

crankshaft in numerical sequence as illustrated

even if the oil level in the reservoir is low.

in figure 4-4.

4-14. Crankcase and Crankshaft

4-15.

Crankcase

and

Crankshaft

R e m o v a l and Disassembly

Cleaning

a. Removal

a . Crankcase. Swab out the lubricating oil

passages in the crankcase with P-D-680 solvent.

(1) Refer to TM 5-4930-207-12 and remove

the compressor assembly.

the vacuum air method. Lubricate bearings im-

(2) Remove flywheel as instructed i n T M

mediately after cleaning.

5-4930-207-12.

Figure 4-4. Crankcase and crankshaft, disassembly and reassembly.

4-5