TM 5-4930-207-34

Section Il. HOSE REEL

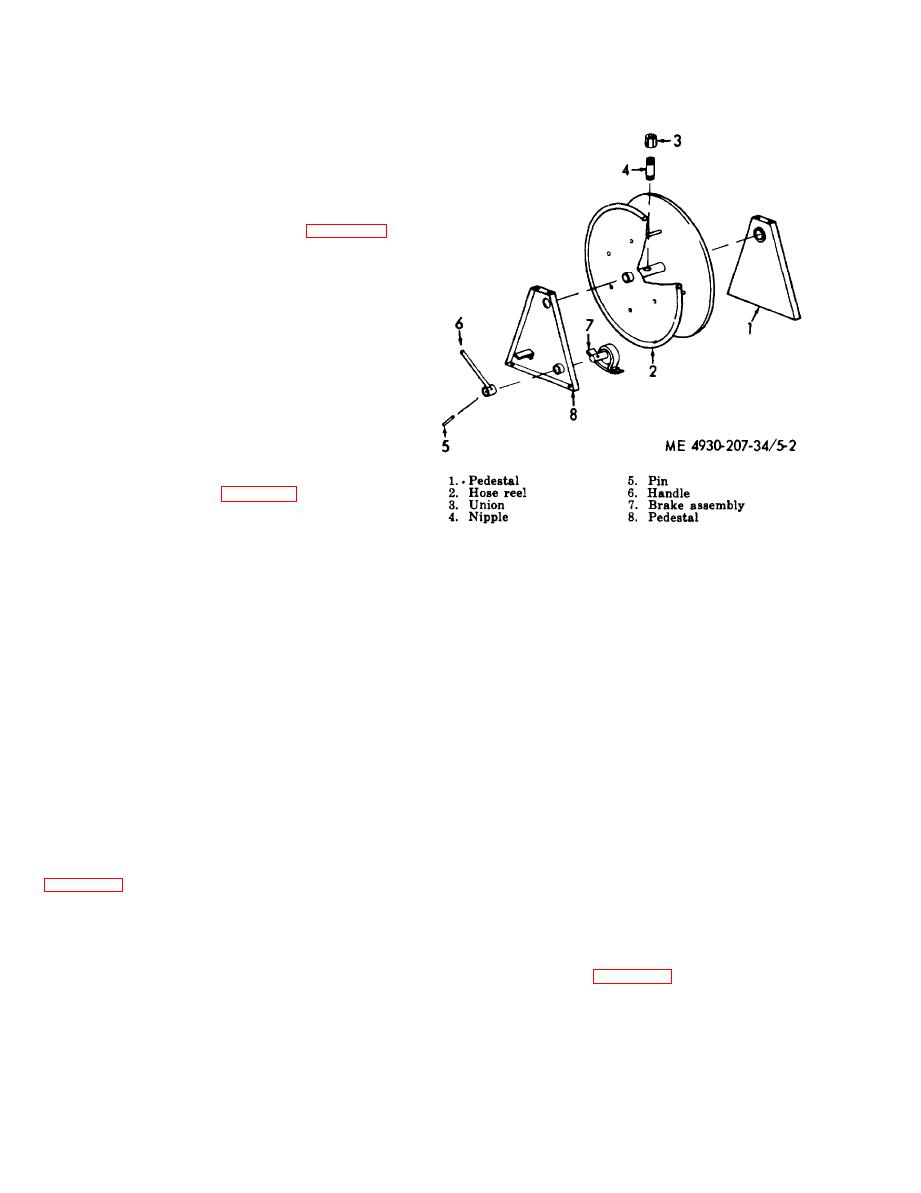

5 - 3 . Hose Reel Removal and

Disassembly

a. Removal. Remove the hose reel as instructed

in TM 5-4930-207-12.

b. Disassembly. Disassemble the hose reel as

illustrated in numerical sequence in figure 5-2.

5-4. Hose Reel Inspection and Repair

a. Inspection.

(1) Inspect pedestals and hose reel for bends,

cracks, or other defects.

(2) Inspect union and nipple for stripped

threads.

(3) Inspect brake assembly, handle, and pin

for excessive wear or other damage.

b. Repair. Repair all parts by replacement.

5-5. Hose Reel Reassembly and

Installation

a. Reassembly. Refer to figure 5-2 and reas-

semble in reverse order.

b. Installation. Install the hose reel as shown

Figure 5-2. Hose reel, disassembly and reassembly.

in TM 5-4930-207-12.

Section Ill.

METERS

b. Inspection and Repair.

5-6.

General

(1) Inspect all parts for wear or leakage.

The meters are designed for dispensing gear and

Replace defective parts.

motor oil, The gear hand meter indicates amount

(2) If lubricant leaks around the fitting body

dispensed in pints and the motor hand meter in

(7) replace O-rings (8, 9).

quarts.

(3) If lubricant leaks around the face dial

(2) replace flat packing (15) and leather washer

5-7. Meters Removal and Disassembly

(14).

a. Removal. Remove meters as instructed in

(4) If lubricant leaks around the lubricant

TM 5-4930-207-12.

inlet replace V-block packing (21) and gasket

(18).

b. Disassembly. A typical disassembly of both

(5) If lubricant leaks around the lever as-

meters is illustrated in numerical sequence in

sembly (25) replace O-rings (29, 30).

5-9. Meters Reassembly and

5 - 8 . Meters Cleaning, Inspection,

Installation

and Repair

a. Reassembly. Reassemble both meters in re-

a. Cleaning. Clean all parts with P-D-680 and

verse of removal, see figure 5-3.

dry with clean lint-free cloth.

b. Installation. Install meters as instructed in

TM 5-4930-207-12.

5-2