over-pressurizing the unit should the other

3-8) by removing the six attaching screws

devices fail.

(76), the ground lead and disconnecting the

electrical leads. Remove the unit from the fuel

b. Installation. Installation is the reverse of

tank (74, fig. 3-8). Tag electrical leads.

removal.

(2) Disconnect the electrical leads from

3-69. Battery

the oil pressure transmitter (44, fig. 3-7) and

unscrew the unit from tee (45). Tag electrical

a. Removal. Remove the two batteries (21,

leads.

and disconnecting the batteries from the bat-

b. Repair. Do not attempt to repair the

tery box (19).

sender units. If they are malfunctioning, re-

place them.

b. Testing. A battery test may be performed

by checking the battery generator indicator on

c. Installation. Installation is the reverse of

the front of control panel for proper charge of

removal.

the battery.

3-68. Safety Devices

c. Installation. Install the batteries in reverse

of removal.

a. Removal.

(1) The low oil pressure switch (43, fig.

cle

trical leads and unscrewing from its mating

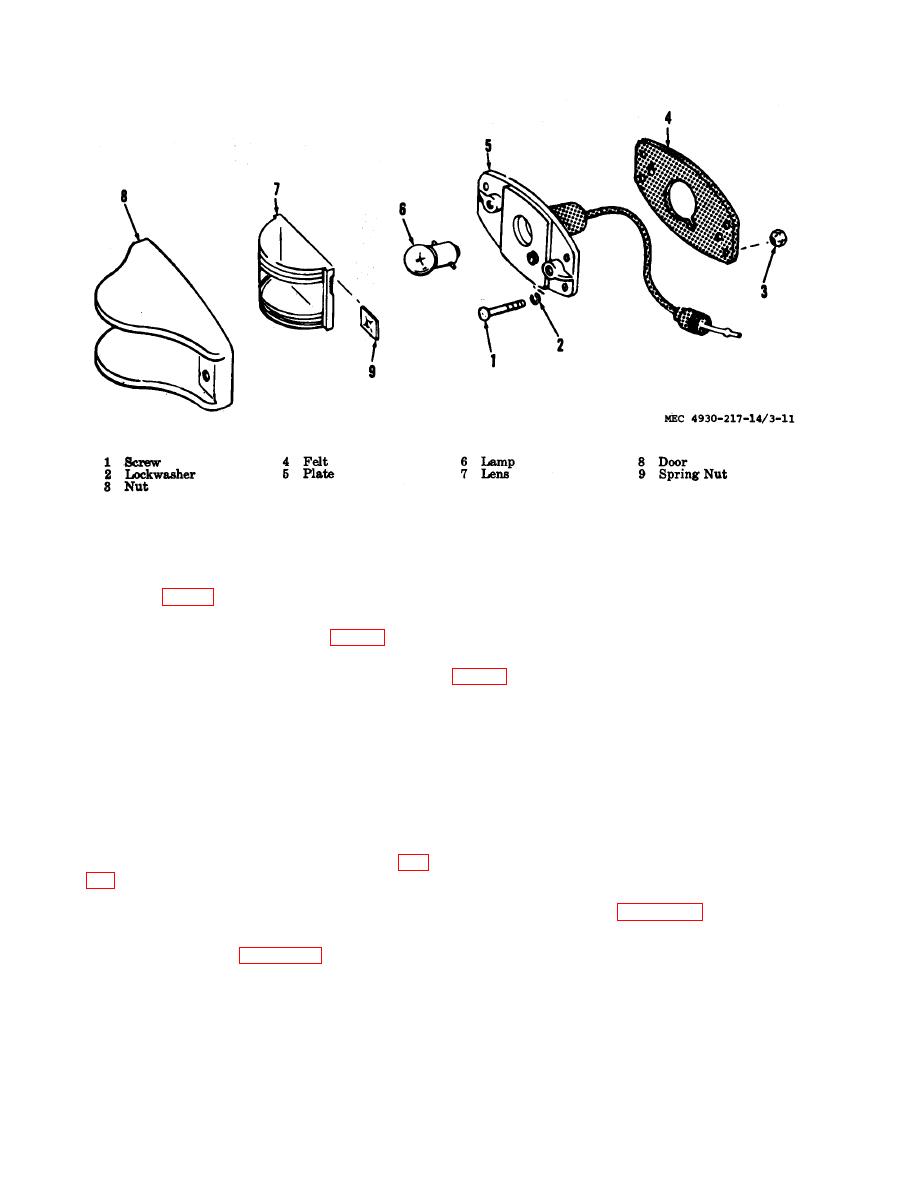

a. Removal. Refer to figure 3-12 for removal

part. Tag all electrical leads.

of the chassis wiring harness and receptacle.

(2) The throttling device (13) can be re-

moved as shown in figure 37. This cylinder

b. Installation. Installation is the reverse of

removal.

assembly is an added safety device to prevent

2-20