221. Flywheel and Rear Engine Support

a. Removal.

(1) Remove the engine-compressor (par. 214) and the housing (par. 128).

(2) Remove the shutter air filter (par. 82a), starting motor (par. 93a), and aftercooler (par. 117a).

(3) Remove the two hex head bolts (14, fig. 94), hex nuts (12) and lockwashers (13) to detach the braces (15)

from the rear engine support (4, fig. 102).

(4) Support the engine-compressor with a cable hooked on the lifting bail (1, fig. 97) to take the weight off the

rear engine support (4, fig. 102).

(5) Remove the nuts (14, fig. 96), spacers (15 and 16), and cap screws (17) holding the rear engine support to

the frame (18).

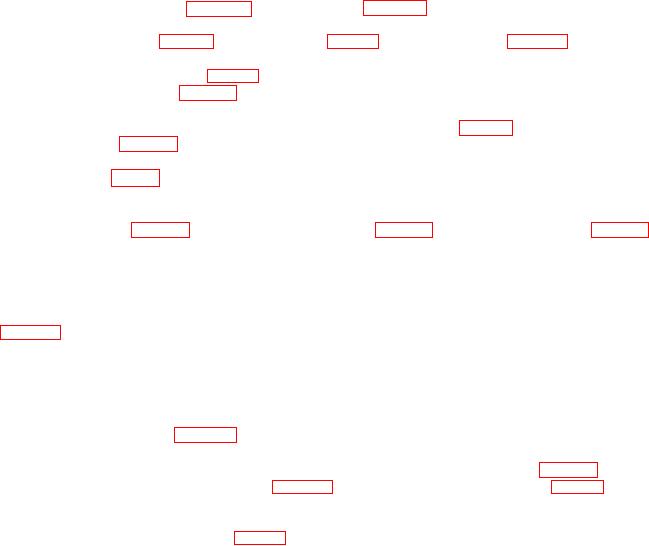

(6) Unscrew the locknuts (1, fig. 102) from the flywheel bolts (10, fig. 103) through the flywheel (2, fig. 102). Lift

off the flywheel and ring gear (3). Remove the six cap screws (5) and lockwashers (6) that fasten the rear

engine support to the crankcase and upper oil pan. Pull the taper pins (7) and lift out the rear engine

support. The hex head bolts (8), hex nuts (11), and lockwashers (10) need not be removed if the timing

indicator (9) is undamaged. The ring gear is integral with flywheel and is not serviced separately.

b. Inspection (fig. 102). Replace the taper pins (7). Replace the timing indicator (9) if bent or cracked. Examine the

ring gear (3) for cracked or broken teeth. Replace both the flywheel and ring gear as an assembly if the ring gear is

damaged.

c. Installation.

(1) Install the timing indicator (9, fig. 102) if it was replaced. Place the rear engine support (4) against the

crankcase and drive in the two taper pins (7). Install the cap screws (5) and lockwashers (6) that fasten the

rear support. Position the flywheel (2) and ring gear (3) over the flywheel bolts (10, fig. 103) through the

crankshaft flange and install the locknuts (1, fig. 102). Install the spacers (15 and 16, fig. 96), cap screws

(17), and nuts (14) that fasten the rear engine support to the frame.

(2) Remove the cable from the lifting bail (1, fig. 97).

231