b. Remove the shim (3), spring (4), guide (5), ball

(6), and seat (7) from the crankcase (14).

c. Unscrew the strainer retainer (8) and remove the

preformed packing (9) from the strainer retainer.

d. Remove the spring (10) and strainer (11) from

the crankcase (14).

e. Unscrew the cap (12) from the connector (13);

unscrew the connector from the crankcase.

38. Cleaning

a. Use a soft brush to clean apertures, slots, and

holes, paying particular attention to the crankcase and

crankshaft passages. Remove carbon deposits in the

heads and valves.

b. Clean all metallic parts except the crankcase

(13, fig. 15) in ultrasonic cleaner. Blow strainers dry with

clean, dry, compressed air.

c. Use an oil base ultrasonic cleaner to clean the

crankcase (14, fig. 16).

Caution

Under no condition should a water base

ultrasonic cleaner be utilized to clean any cast

iron component.

39. Inspection

a. Inspect all parts visually for obvious signs of

wear or damage.

b. Inspect all internal and external threads and

discard any part having more than two damaged threads

in any one location.

c. If the crankshaft has been disassembled,

measure the diameters of the shaft. The front bearing

seating surface should be between 1.2501 and 1.2505 in

O.D. The rear bearing seating surface should be

between 1.5749 and 1.5753 in O.D. The keystone

assembly seating surface should be between 0.8750 and

0.8753 in O.D.

d. If

the

keystone

assembly

has

been

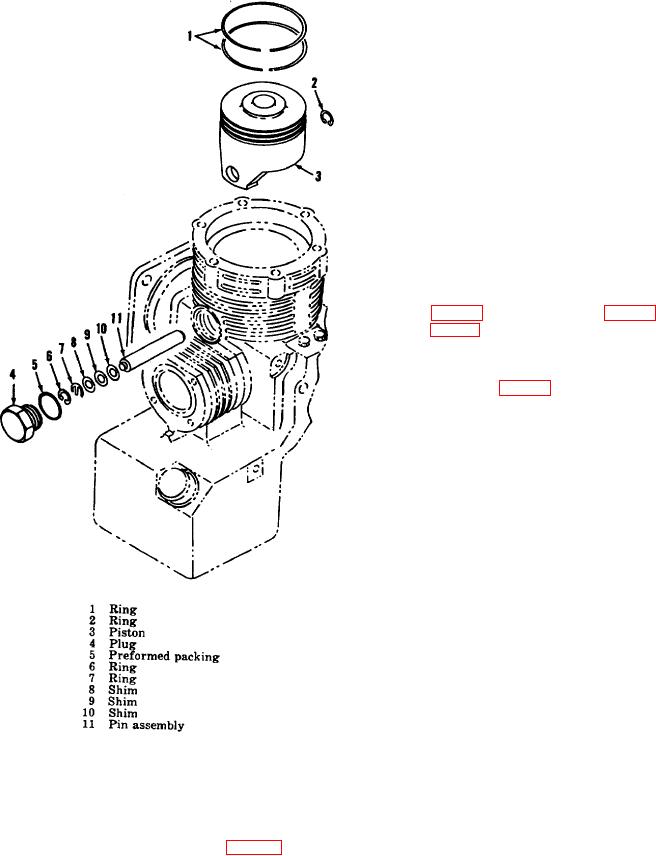

Figure 14. First stage piston, exploded view.

disassembled, measure the diameters of the keystone

bores. The crankshaft bore of the keystone assembly

bearing (7) from the crankshaft using a bearing puller or

should be between 0.8759 and 0.8763 in I.D. The first

brass drift and hammer.

stage piston pin bore of the keystone assembly should

be between 0.5008 and 0.5012 in I.D.

37. Crankcase Section Disassembly (fig. 16)

e. Inspect the valves and valve seats to see

a. Unscrew the spring retainer (1) and re 24 move

the preformed packing (2) from the spring retainer.

AGO 5548A

24