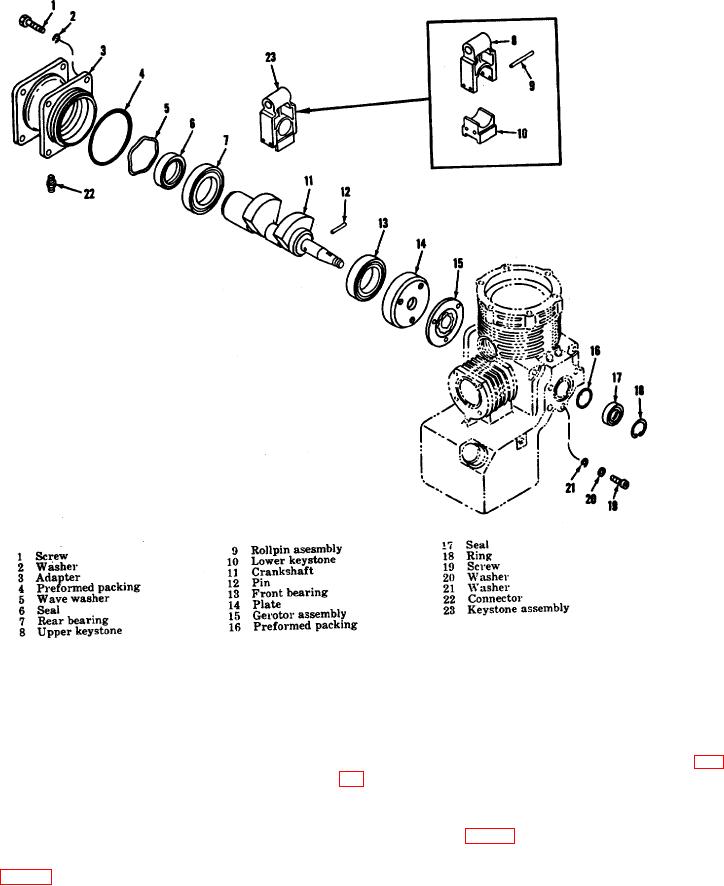

Figure 15. Keystone-crankshaft, exploded view.

that they are free of nicks, scratches, or burrs.

or burrs. Measure the O.D. and check that it is between

0.5001 and 0.4998 inch.

f. Inspect all cylinder bores to determine that the

internal surfaces are free of nicks, scratches, chipping,

i. Inspect the oil sump of the crankcase (14, fig.

carbon. deposits, or any unusual wear patterns.

16) and determine that the sump is free of dents or

g. Inspect all plungers and pistons to determine

abrasions that might develop into leaks.

that the outside wear surfaces are free of nicks,

j. Inspect ports, bores and pressure relief holes in

scratches, burrs, or carbon deposits. Check that the

the crankcase (14, fig. 16) for cleanliness and clogging.

piston ring grooves are free of carbon.

h. Inspect the outside surface of the piston pin

k. Replace all defective components, preformed

assembly (11, fig. 14) to determine that the pin is round

packings, springs, and parts furnished in the repair kit

and free of nicks, scratches,

allocated to fourth echelon maintenance personnel.

AGO 5548A

25