TM 3-1040-263-34

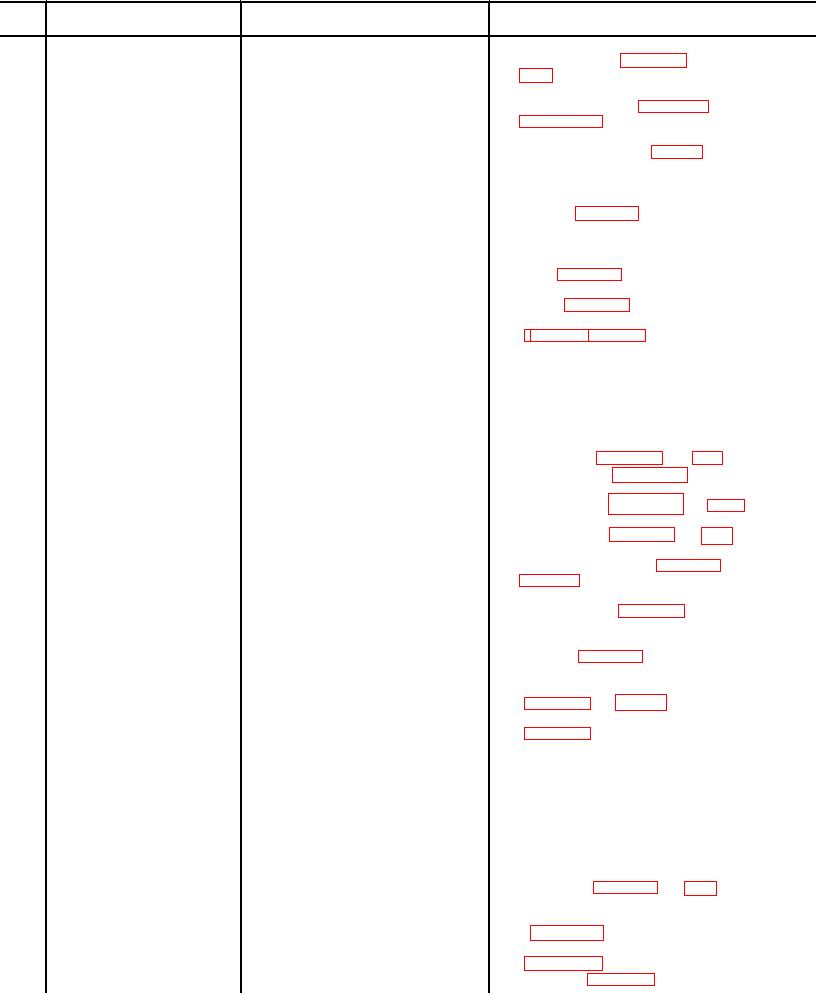

Table 4-4. Troubleshooting--Continued

Item

No.

Malfunction

Probable cause

Corrective action

9

Low air flow-Continued

h. Scored cylinder, plunger, or piston

Replace faulty cylinder, plunger, or

assembly.

piston assembly (para 4-27 through

i. Incorrect head clearance ---------

Check head clearance(para 4-27

2

Popping or leaking second-

a. Incorrect positioning of heads

Check position of heads (fig. 4-9).

stage relief valve.

b. Foreign matter between intake

Clean

valve and seating surface.

c. Seized 3rd-stage plunger and cy-

Replace faulty third-stage plunger an d

linder,

cylinder (para 4-29).

d. Sticking 3rd-stage intake and dis-

Clean

charge valve.

e. 3rd-stage intake or discharge

Replace 3rd-stage valves and valve

valves defective.

plate (para 4-29).

f. 3rd-stage intake or discharge

Replace distorted 3rd-stage valve or

valves or sprints distorted.

spring (para 4-29).

g. Clogged 3rd-stage heat exchanger

Clean or replace faulty component

or aftercooler.

3

Low oil pressure .---------

a. Loose connections on oil supply

Tighten connections

tube.

b. Low oil level in oil sump.

Fill oil sump (TM 3-1040-26 -12)

c. Clogged oil strainer -----------

Clean screen of oil strainer (TM 3-

1040-263--12).

d. Excessively worn keystone or

Measure clearances and replace worn

crankshaft journal.

components (para 4-33 and 4-34).

e. Faulty oil pump-------------

Replace oil pump (para 4--19)

4

High oil pressure----

a. Faulty oil pump - ----------

Replace oil pump (para 4 --19 and 4-21)

5

Oil Leakage---------

a. Oil pump seal damaged -------

Replace oil pump (para 4-19 and 4-21)

b. High blowby or through pump-------

Refer to items 6 and 7 below

c. Leaky preformed packing --------

Place preformed packing (para 4-19

d. Loose connections or fittings

Tighten all connections and fittings

e. Drain plug

Replace drain plug (para 4-23b)

6

High blowby

a. Compression rings worn, scored

Check and, if necessary, replace rings

cracked, or incorrectly

properly (para 4-27b).

Assembled.

b. Plunger or cylinder worn or

Replace worn or scored component

scored.

(para 4-28b and 4-29b).

c. Piston assembly or cylinder worn

Replace worn or scored component

or scored.

NOTE

High oil through put occurs

when there is excessive oil

flow between the keystone

and crankshaft journal-as

detected by oil leakage from

blowby port.

7

High oil through put

a.

Excessive keystone or crankshaft

Determine worn component, and replace

journal clearance.

as required (para 4-33 and 4-34).

b.

High oil pressure

Refer to item 4 above

8

Pumping oil through compres-

a.

Poor fit of 1st-stage piston

Replace 1st-stage piston or cylinder

sor

assembly and cylinder.

b.

Poor fit of 2nd-stage plunger and

Replace 2nd stage plunger or cylinder

cylinder.

c.

Damaged or worn rings

Replace rings (para 4-27b)

4-30