ENGINE

Section VI.

(3) Inspect all metal parts for breaks,

bends, nicks, groves, cracks, dents,

(fuel injection side)

obstructions, broken welds, damaged

a. Removal and Disassembly. Remove the ex-

or worn threads, and corrosion. Use

ternal parts on the fuel injection side of the

a fine stone to remove small nicks or

engine as shown in figure 39.

burrs. Replace all damaged parts.

(1) Disconnect the fuel injection lines (6)

c. Reassembly and Installation. Reassemble

from the injection pump (22), and noz-

and install external parts on the fuel injection

zle holders (9).

side as shown in figure 39.

Note. Clean the side of the engine before

(1) Clean carbon and dirt from counter-

disconnecting the injection lines. Use clean

bore and gasket seat in the cylinder

fuel to flush the fittings, so that dirt cannot

head before installing nozzle holder

enter the injection system. As each line is

assembly, as small carbon particles on

removed, plug the pump openings and cap

the nozzles with clean (preferably plastic)

seating surfaces will clog assembly

plugs and caps. Tape the ends of all lines.

and permit blow-up. A reaming tool

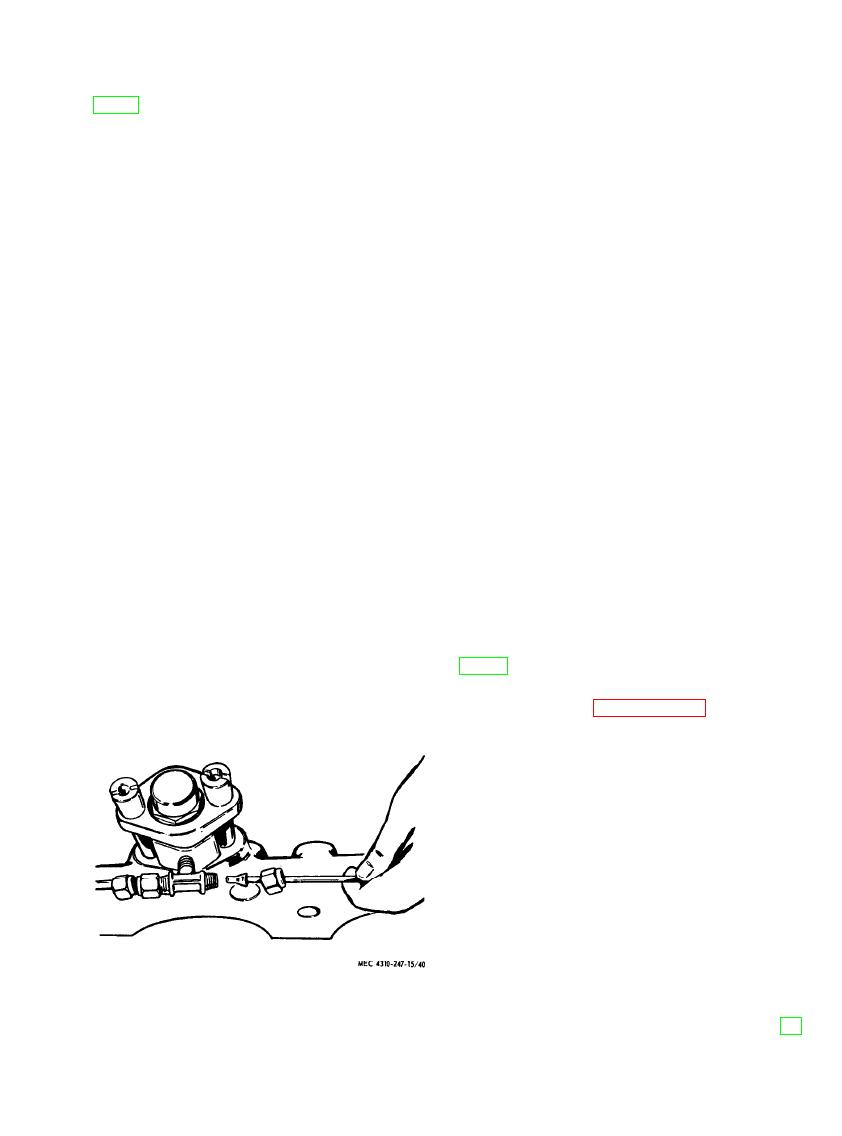

(2) Remove nozzle holders (9) and leak-

or round piece of wood or brass, prop-

off tube assembly (12, 14 and 15). Be-

erly shaped, may be used.

gin with the No. 1 nozzle holder (fig.

(2) Install nozzle holders and leak-off tube

40).

assembly, starting with nozzle holder

Caution: Do not strike nozzle tips

No. 4. When tightening leak-off con-

against hard surface or damage will

nections, always hold the fittings with

result. Nozzle holders should not be

a wrench to keep them from turning

disassembled unless cleaning or other

while tightening the nuts.

service is needed.

screws to 14-16 ft-lb. Pull down evenly in

b. Cleaning, Inspection, and Repair.

three stages, at 5, 10, and 16 ft-lb, respec-

(1) Clean all metal parts in an approved

tively.

cleaning solvent and dry thoroughly.

(3) Remove all caps, plugs and protective

Wipe nonmetallic parts with a clean,

tape, and connect the fuel injection

dry cloth. Clean hose with soap and

lines between the pump and nozzle

water.

holders.

(2) Check line, tube, and hose assemblies

for continuity. Inspect hose for cuts,

worn or weak spots, and deterioration.

a. Removal and Disassembly.

Replace if unserviceable.

(1) Refer to paragraph 115 and remove

t h e engine.

(2) Remove all oil lines which connect

balancer housing to crankcase at both

housing and crankcase ends.

(3) Loosen screws (84 and 85, fig. 41) and

pry the balancer loose from the dowels

(59). Remove screws and balancer.

(4) Remove the nut (51) and washer (52)

from idler gear stud (58) and press

o u t stud.

(5) Remove oil pump wire (9), oil screen

(10), frame (14), screws (25), and

oil relief shield (27).

(6) Remove screws (28 and 30) and re

move oil pump body (36).

Figure 40. Disconnecting nozzle leak-off line.

AGO 8166A