on crankshaft gear must be in the

lowest position. Mount the complete

balancer assembly to the crankcase

with the capscrews (84 and 85) only

finger tight.

(19) Reconnect all oil lines from balancer

to engine.

(20) Line up the marked teeth on the

crankshaft gear with the marked tooth

on top of the counterweight idler gear.

Tighten screws holding balancer hous-

ing to engine crankcase to 125 to 130

foot-pounds. Check timing for lineup

after balancer is tightened to be sure

that you are not one tooth off. Check

backlash between crankcase and idler

gear all the way around by rotating

one complete revolution. Crank and

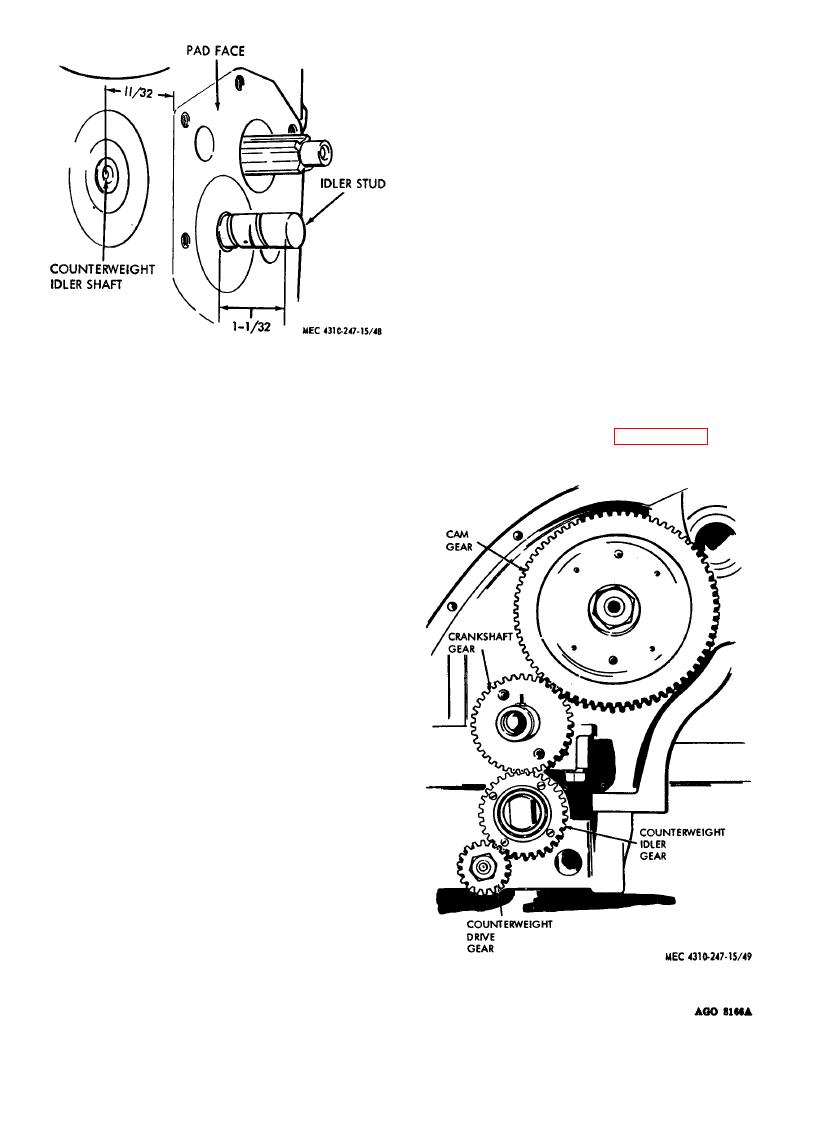

Figure 48. Shaft location dimensions.

balancer idler gear must have .004 to

capscrew and lockwasher assemblies

.0075 inch backlash.

(12). Torque screws to 10 foot-pounds.

(21) Tighten capscrews (84 and 85) to

Assemble oil pump strainer screen

torque as given in paragraph 5.

(10).

(16) Assemble idler gear (64), idler gear

stud (58), spacer (63), and idler gear

bearing (55). Assemble retainer

plate (56) to idler gear with screws

(57). Tighten screws securely and

stake two places in each screw so

metal from gear is driven into screw

slots.

(17) Assemble idler gear assembly (step

15) into housing. Secure with washer

(52) and nut (61). Line up marked

tooth space on idler gear (47) with

marked tooth on counterweight drive

gear (62). Rotate balancer idler gear

to bring marked tooth space on idler

gear and marked tooth on counter-

weight drive shaft gear in line. Due to

the gear ratio of the two gears, the

markings line up only once every 31

turns, so it maybe necessary to rotate

the gears several revolutions. Check

backlash of gears for .004 to .007

clearance in four places. Assemble

lockwasher (61) and nut (61). Torque

nut to 75 foot-pounds (fig. 49).

(18) Turn engine crankshaft until the

marked tooth space on the crankshaft

gear lines up with the marked teeth

on the cam gear. The marked teeth

Figure 49.

Gear alignment.

80