(22) Refer to paragraph 115 and install

t h e engine.

(23) Lubricate the engine in accordance

with the current lubrication order.

Note. After assembly and on initial run

at 1,800 rpm, oil pressure should be 30 to

40 psi. If it is below this figure, install

washers in cavity of oil relief plunger. Re-

assemble oil relief plunger spring, oil relief

spring retainer and cotter pin.

(manifold side)

a. Removal and Disassembly. Remove the

external parts on the manifold side of the en-

gine as shown in figure 60.

Note. Provide a clean place to work, and clean the

engine exterior before you start disassembling.

(1) Drain water from engine and discon-

nect radiator outlet hose.

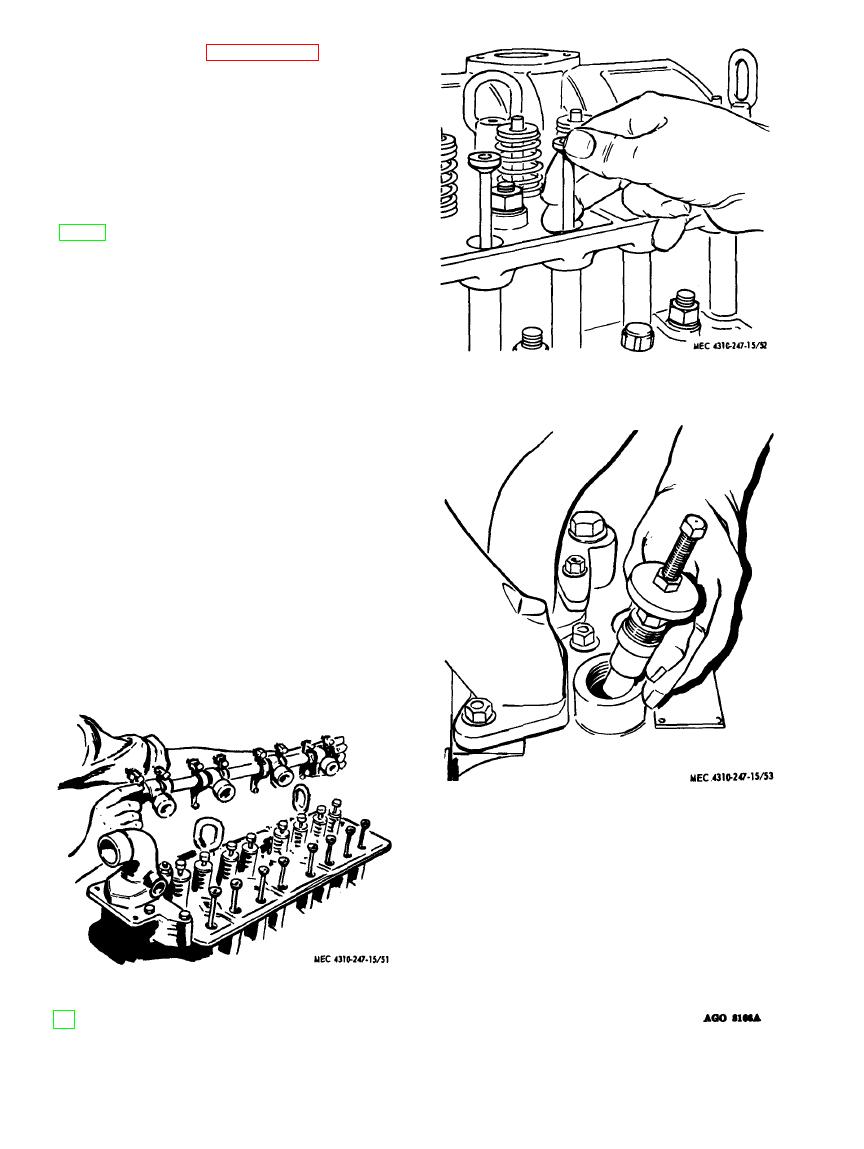

Push rod disassembly.

Figure 52.

(2) Remove cylinder cover (18) by taking

out the screws holding it to the rocker

arm supports. Remove gasket (19).

(3) Remove rocker arm shaft assembly

and push rods (fig. 51). Grip the push

rods and snap them sideways out of

the tappet sockets (fig. 52). This

breaks the hydraulic connection, and

permits lifting the push rods out with-

out disturbing the tappets. (If tap-

pets are lifted out of the guides, they

will have to be reassembled through

the opening in the block when only the

cylinder head is removed for servic-

ing.)

(4) Disconnect the injection and leak-off

lines at both the nozzle and pump con-

Figure 53. Energy cell body removal.

nections and immediately cap the fit-

tinge to prevent dirt from entering.

(5) Loosen and remove the nuts holding

the cylinder head (36, fig. 50) to the

block (69) .

(6) Lift the cylinder head off the engine

and carry it to a clean bench for fur-

ther disassembly. Remove and discard

old gasket (37).

Figure 51. Rocker arm shaft removal.