TM 5-4310-354-14

(4) Install the oil pan (para 7-15. c, as applicable).

(8) Install the fuel injection pump (figure 7-15),

assembling the pump gear (24, figure 7-49),

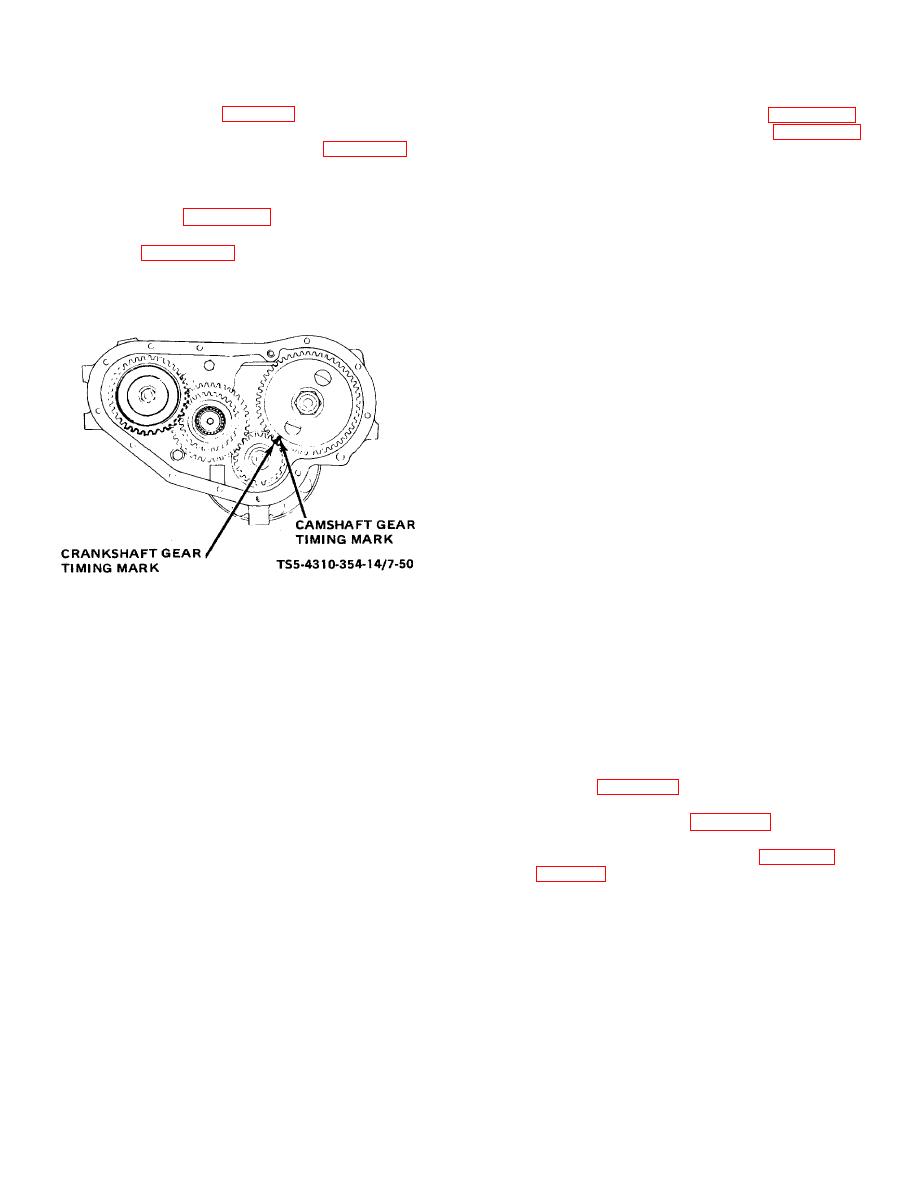

(5) Install camshaft gear key (21, figure 7-49) in,

washer (23), and nut (22) on pump shaft.

keyway on camshaft. Install camshaft gear (20)

on camshaft with timing mark on the camshaft

(9) Use a small amount of sealing compound in the

gear aligned with crankshaft gear timing mark as

seal (18) bore of the gear housing cover (12)

shown in figure 7-50.

Insert a brass bar

and press seal (18) into cover (12). If new seal

between the two gears to keep camshaft gear

is precoated, sealing compound is not required.

(20, figure 7-49) from turning and install

Cement a new gasket (13) to gear housing

camshaft nut (19). Torque the nut to 125 to 135

cover (12).

foot-pounds (17.2875 to 18.6705 kg-m).

Remove brass bar.

(10) Clean and polish the oil seal surface of the

crankshaft to remove any nicks and scratches

which could damage the seal (18). Use an oil

stone or very fine emery cloth to remove nicks

and burrs and polish with crocus cloth. Cover

the crankshaft keyway with a thin feeler gauge

to protect seal (18) when installing gear housing

cover (12).

(11) Apply a thin coating of oil soap to the seal (18)

bore and the seal surface on the crankshaft. If

new seal (18) is oil treated, additional lubrication

is not required. Take care to keep the seal

surface clean during reassembly. Install the

gear housing cover (12) and attach to gear

TS 5-4310-354-14/7-50

housing (34) with lock washers (8, 9, 11), cap

screws (5, 6, 7), and nut (10).

Figure 7-50. Aligning drive gear timing marks.

(12) Install gasket (17), thrust plate (16), and attach

to gear housing cover (12) with lock washers

(6) If removed, install idler shaft (29). If removed,

(15) and cap screws (14).

press bearing (28) into idler gear (27).

Assemble idler gear and bearing assembly onto

(13) Place pulley key (4) in crankshaft keyway and

shaft (29).

Use Loctite, or equivalent, on

install pulley assembly (3). Install lock washer

threads of cap screw (25) and attach idler gear

(2) and nut (1). Torque the nut (1) to 125 foot-

(27) to shaft (29) with washer (26) and cap

pounds (17.2875 kg-m).

screw (25). Torque cap screw (25) to 25 foot-

pounds (3.4575 kg-m).

(14) Install the alternator bracket, screws, and lock

washers (figure 4-25).

(7) Turn the crankshaft so that flywheel timing

marks indicate 20 BTDC for the number 1

(15) Install the fan and belt (figure 7-33).

cylinder.

(16) Install the engine on the unit (para 5-12 and

7-57