TM 5-4310-354-14

cracks, or other damage.

Replace any

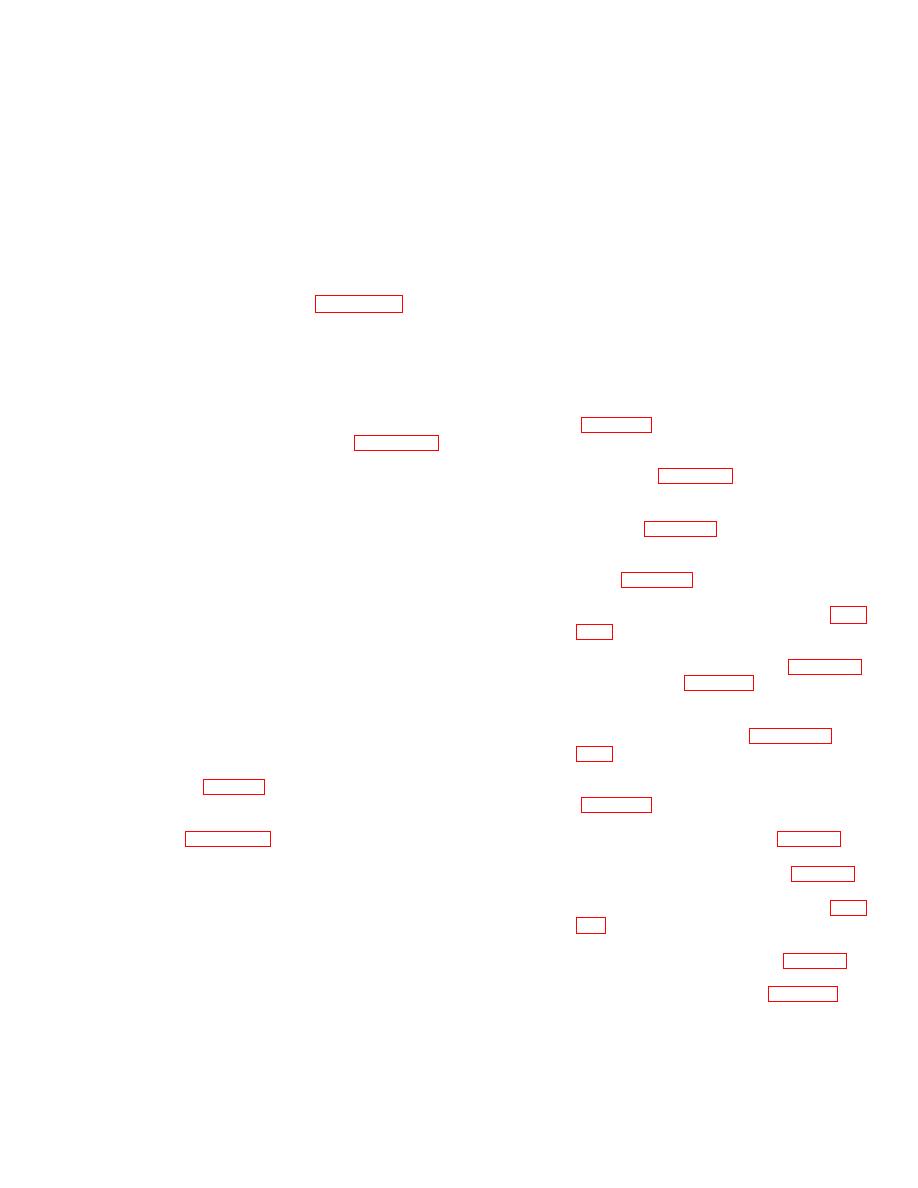

(e) Install main bearing caps (12, 10, 9,

damaged parts.

8) in their original positions to

maintain bearing alignment.

The

(15) Check all the threaded holes in the

caps are marked with the number of

cylinder block. Make sure they are clean

the cylinder in which they are used.

and the threads are in good condition.

Attach the caps to cylinder block

Clean up damaged threads in the tapped

with cap bolts (7, 11).

holes with a same-size tap or retap larger

and install helical thread inserts, if

(f) Install two gaskets (6) and side

necessary.

covers (5). Attach to cylinder block

(28) with lock washers (4) and cap

(16) Inspect the side covers (figure 7-63) and

screws (3).

bayonet gauge tube for cracks, dents,

distortion, and other damage. Replace

(g) If removed, press oil filler tube (2)

any damaged parts.

into cylinder block (28) and install

the oil level gauge (1).

c. Reassembly and Installation.

(2) Install the crankshaft and main bearings

(1) Reassemble the cylinder block in reverse

numerical sequence shown in figure 7-63

as follows:

(3) Install pistons and

connecting

rod

assemblies (para 7-24).

CAUTION

(4) Install the camshaft

and

camshaft (para 7-22).

Make certain that all open oil passage

pipe plugs are installed. Be sure the

(5) Install gear housing, timing gears, and

lower

camshaft

thrust

flange

cover (para 7-20).

mounting hole is plugged with

setscrew (20). This is the rear end

(6) Install the bellhousing and flywheel (para

opening of the oil passage for the

rocker arms and must be plugged to

prevent oil leakage.

(7) Install the oil pump assembly (para 7-16)

(a) Install a new identification plate (27)

and the oil pan (para 7-15).

onto cylinder block (28) using new

screws (26).

(8) Install the cylinder head assembly and

rocker arm assembly (para 7-13 and

(b) Install cylinder head studs (25 thru

21) on cylinder block (28) as shown

in table 7-3.

(9) Install the water pump and fan assembly

(c) Make certain that setscrew (20,

(10) Install the fuel injection pump (para 7-8).

pipe plugs (18, 17), and dowel pins

(16) are installed in cylinder block

(11) Install the fuel injection nozzles (para 7-6).

(28).

(12) Install the starting motor assembly (para

(d) Install oil pan adapter studs (15),

gear housing stud (14), and

bellhousing studs (13) into cylinder

(13) Install the alternator assembly (para 7-2).

block (28).

(14) Install the engine in the unit (para 5-12).

7-74