TM-5-4310-389-14

19.

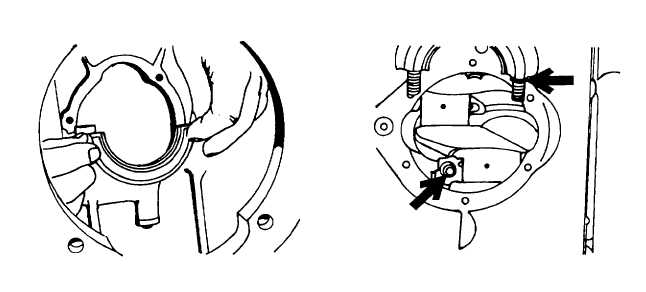

Turn the engine upside down. Install the halves of bearing shells of the middle crankshaft bearing in the

crankcase and bearing cap, respectively; check the identification marks. Fit the halve of thrust ring with the

smooth surfaces to the bearing cap and bearing web sides, respectively apply grease to retain them in position

(figure 5-24).

NOTE

A locating pin must be inserted on either side of the bearing cap. The thrust ring halves should locate

against these pins.

20.

Lubricate the middle crankshaft journal with clean engine oil. Install the crankshaft from the flywheel end of the

crankcase.

21.

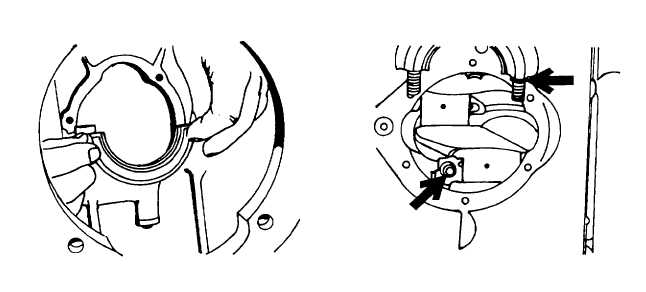

A centering sleeve must seat in each of the bolt holes in the bearing cap and bearing web (figure 5-25).

22.

Bearing cap must be fitted with its identification number corresponding to and in the same direction as that

stamped on the crankcase.

23.

Insert the bearing cap bolts. Torque in accordance with the instructions given in torque specifications (use

device No. 003-1102, figure 5-26).

24.

Oil the journal at the flywheel end of the crankshaft. Pay attention to the race of the rear crankshaft seal. If the

crankshaft exhibits a groove due to the rear crankshaft seal, the latter should be moved in the end shield on the

flywheel side (use thrust ring of press-in device No. 003-0670).

Figure 5-24. Fitting Thrust Ring

Figure 5-25. Inspect for Dowel

Centering Sleeves

5-19