TM-5-4310-389-14

9.

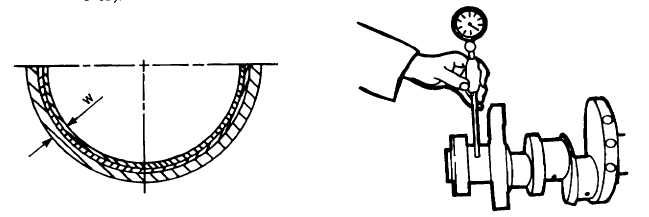

Measure width of locating bearing journal of the crankshaft (figure 5-63).

10.

Assemble the thrust rings on the locating main bearing and calliper the overall width.

11.

Measure end clearance. Compare with the values given in the specifications (table 4-5). If necessary, install

new stop rings.

12.

Remove the radial seal ring from the back-end shield.

13.

If the main bearing journal has not been reground and the bearing bushing shows no sign of damage or wear,

gauge the bearing bore at two diagonal points.

14.

Compare measure values with the specifications in table 4-5. If necessary, fit new bearing bushing.

15.

Draw the bearing bushing in flush, align with oil holes in the housing.

16.

Install a new radial sealing ring in the back-end shield with the sealing lip facing the bearing bushing; press in

so that the back face is flush.

REPAIR

REPLACE

e.

Reworking Cylinder Seating on Crankcase.

1.

Clean the seating area and remove paint residues. Place supporting brackets in position (figure 5-64).

2.

Mount refacing device No. 003-0505 and retaining bolts to such an extent that the refacing device is still

movable (figure 5-64).

3.

Center refacing device by means of the centering fingers (arrows) and fasten (figure 5-65).

Figure 5-62. Standard and Oversize Wall

Figure 5-63. Measuring Width of Locating

Thickness

Bearing Journal of Crankshaft

5-37