TM 9-4310-397-14

6-6. ROCKER ARMS, CYLINDER HEAD, AND VALVES REPLACEMENT. - Continued

NOTE

If the rocker arm has been damaged by a valve failure, replace it and push rod when replacing

valve.

(4)

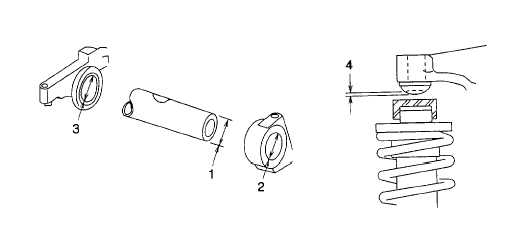

Inspect rocker arm shaft for severe scratching, scoring, or excessive wear at points of rocker arm contact.

Also check shaft for straightness. Rocker Arm Assembly Specifications are as follows.

Rocker Arm Shaft OD (Figure 6-25, 1) (New) .............. ..

0.787 - 0.788 in. (19.99 - 20.02 mm)

Wear Tolerance .............................................................

0.002 in. (0.05 mm)

Rocker Arm Shaft Support ID (2) (Max.)............................... 0.794 in. (20.17 mm)

Rocker Arm ID (3) (Max.) ............ ...................................

0.790 - 0.792 in. (20.07 - 20.12 mm)

Wear Tolerance ....................... ......................................

0.002 in. (0.005 mm)

Figure 6-25. Rocker Arm Specifications

(5)

Check rocker arm and adjusting screw (Figure 6-23, 2) for damage. Visually inspect rocker arm for hairline

cracks. Replace if necessary.

NOTE

Be sure all oil holes in rocker arm shaft are clean and open.

(6)

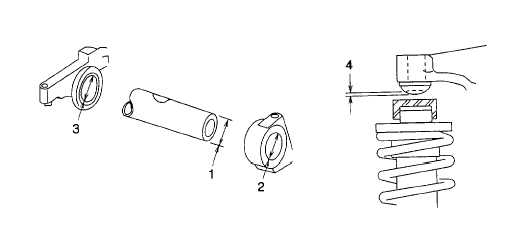

Check for cups or concave wear (Figure 6-25, 4) on ends of rocker arms where they contact wear caps. If

wear exists, replace rocker arm.

(7)

Inspect push rods for wear and damage.

6-26