TM 9-4310-397-14

(8)

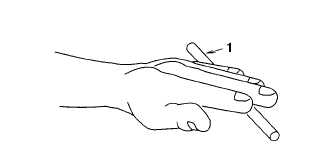

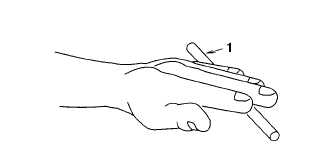

Check push rods (Figure 6-26, 1) for straightness by rolling on a flat surface.

Figure 6-26. Inspect Push Rods

(9)

Replace defective push rods.

(10)

Inspect valve springs.

(a). Inspect valve springs for alignment, wear and damage.

(b). Put springs on a flat surface to see that they are square and parallel.

(c). Check valve spring tension using spring compression tester (item 13, section III, appendix B) and the

specifications given for the valve spring.

NOTE

Free length of springs differ slightly, but compressed height must be the same.

Valve Spring Specifications

Compression

Height

54-62 lb force (240-276 N). ..............................................

1.81 in. (46 mm)

133-153 lb force (591-680N) ............................................

1.36 in. (34.5 mm)

(11)

Inspect and measure valves.

(a)

Visually inspect valves to determine if they can be restored to a serviceable condition. Replace valves

that are burned, cracked, eroded, or chipped.

6-27