FIELD AND DEPOT MAINTENANCE INSTRUCTION

Section I. OVERHAUL AND REPLACEMENT STANDARDS

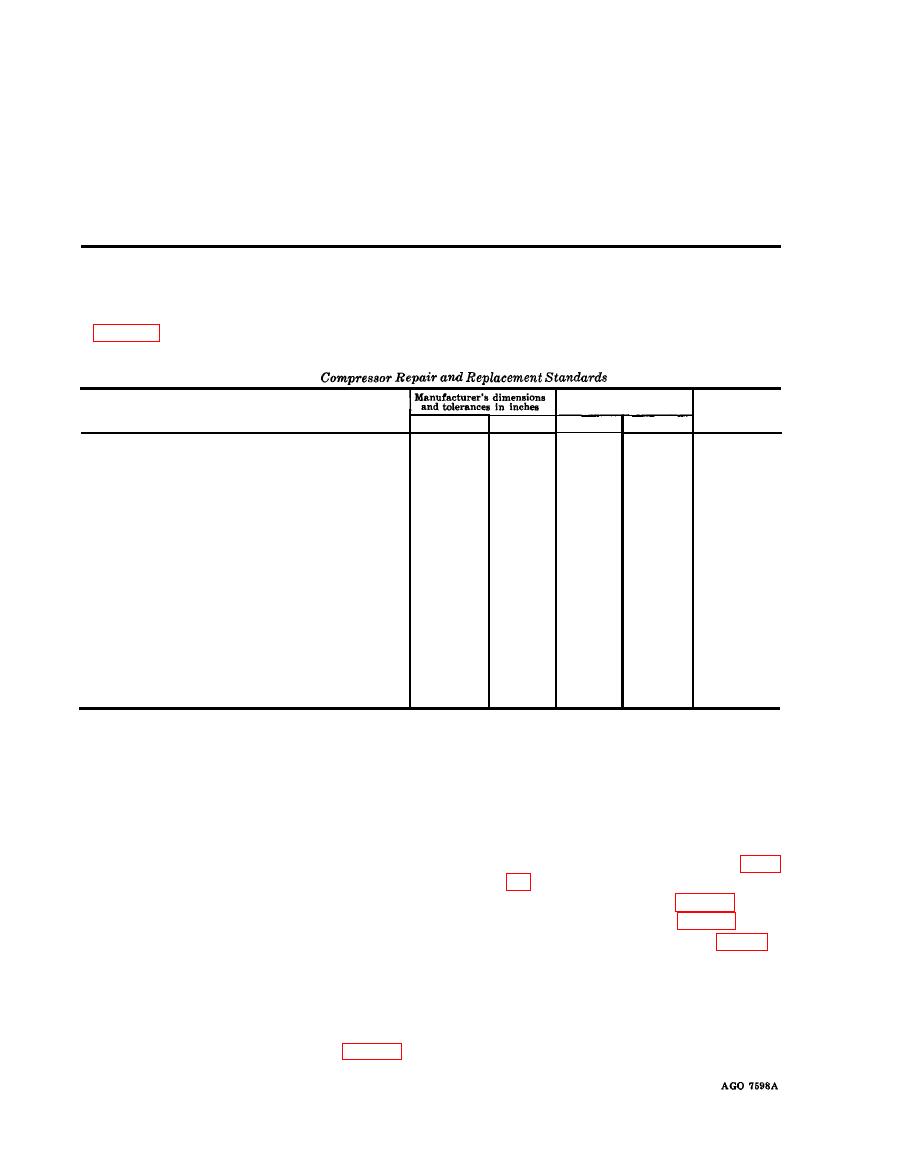

and clearance for the air compressor.

Maximum

Desired clearance

allowable wear

and clearance

Min.

Max.

Min.

Max.

Cylinders

Bore,

low-pressure

-----------------------------------------

------

3.2495

0.004

------

3.2505

Bore,

High-pressure

---------------------------------------

------

------

1.7505

1.7495

0.002

------

------

------

Out-of-round

------------------------------------------------

0.001

------

Taper

------

------

0.001

------

------

-------------------------------------------------

Crankshaft

1.376

Journal

(rod)

size

------------------------------------------

1.375

Taper

----------------------------------------------------------

------

______

------

0.001

------

Out-of-round

------------------------------------------------

------

------

------

------

0.0005

End

play

-----------------------------------------------------

0.000

------

------

0.002

and

Pins

Piston,

Low-pressure

-------------------------------------

0.005

0.003

3.2465

3.2455

0.005

Piston,

High-pressure

------------------------------------

0.0035

0.0015

1.748

1.747

0.003

Pin,

low-pressure

-------------------------------------------

0.0005

0.0001

0.9377

0.9375

Pin,

high-pressure

----------------------------------------

0.0005

0.0001

0.7505

0.750

Connecting

Rod

Bearing,

id

--------------------------------------------------

0.007

0.0001

1.357

1.353

Bearing,

side

clearance

----------------------------------

------

0.010

------

0.017

No special tools are needed to perform field and depot maintenance on these air compressors.

No special equipment is needed to perform the field and depot maintenance on these air compressors.

Section Il. AIR COMPRESSOR ASSEMBLY

(2) Disconnect the intercooler and the

109. General

aftercooler from the manifolds (pars.

The compressor assembly on Model OEH-

34-60-ENG-1 and Model LP-512-ENG is a

(3) Remove the side plates (par. 98).

two-stage, two-cylinder, air cooled unit. There

(4) Remove the air cleaner (par. 85).

is one low-and one high-pressure piston operat-

(5) Revolve the crankshaft (13, fig. 24)

ing off the crankshaft. The crankshafts sup-

until the connecting rod nuts (8) are

ported at either end by ball bearings.

accessible through the side of the com-

pressor crankcase.

Rods and Cylinder Block

(6) Remove the 4 nuts (8) lockwashers

a. Removal and Disassembly.

(7) 1 oil scoop (11),2 lower half bear-

(1) Remove the tube assemblies (par. 97).

ings (10), and the 4 brass shims (5)