TM 5-4310-276-14

Table 4-2. Troubleshooting (cont)

Malfunction

Test or Inspection

Corrective Action

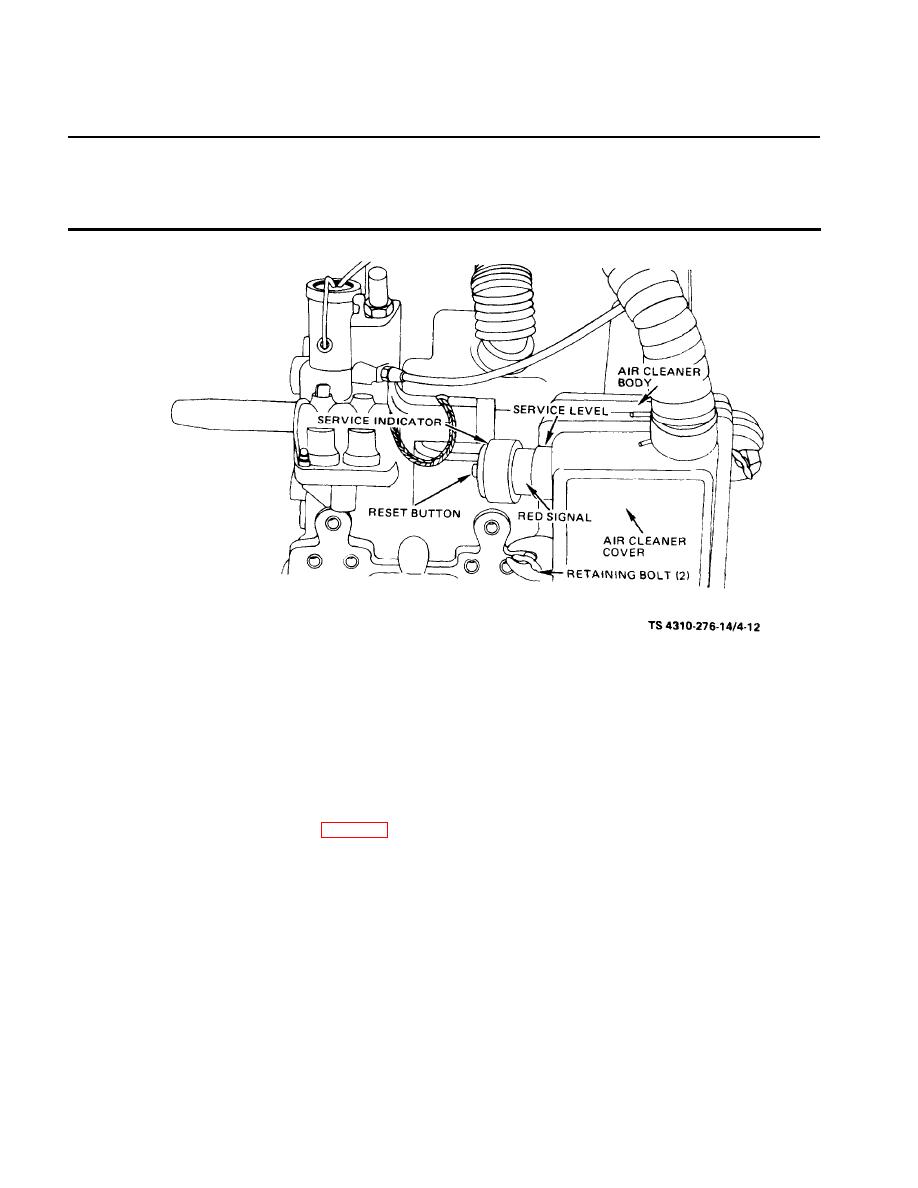

(2) Loosen retaining bolts.

(3) Wipe out inside of air cleaner cover and body.

(4) Remove element from air cleaner body and blow out with compressed air from clean side

to dirty side of element.

(5) Reinstall element, cover, and bolts.

Step 3. Inspect for defective plug.

Clean, regap or replace plug.

a. Removal.

(1) Using figure 4-8 as guide, loosen the connector nut on spark plug end of the cable.

(2) Remove the spark plug from the cylinder head.

h. Cleaning and Inspection.

(1) Clean spark plug in a compressed air spark plug cleaner. Remove abrasive material with

clean, dry compressed air.

(2) inspect for excessive burning, pits, cracks or broken ceramic insulation. Inspect threads

for burrs or evidence of having been stripped or crow-threaded.

(3) Test the firing power of the spark plug on a suitable spark plug tester.

(4) Measure the electrode gap; 0.028 inch (0.071 cm) to 0.033 inch (0.083 cm), using a leaf or

wire gage. Bend the outside electrode until the desired gap is attained.

(5) Replace plug if necessary

c. Installation.

(1) Install spark plug.

(2) When installing the spark plug, make certain the gasket is serviceable and properly in-

stalled. Torque spark plugs to 275 to 300 inch-pounds.

(3) Tighten cable connector nut on spark plug.

4-18