TM 5-4310-354-14

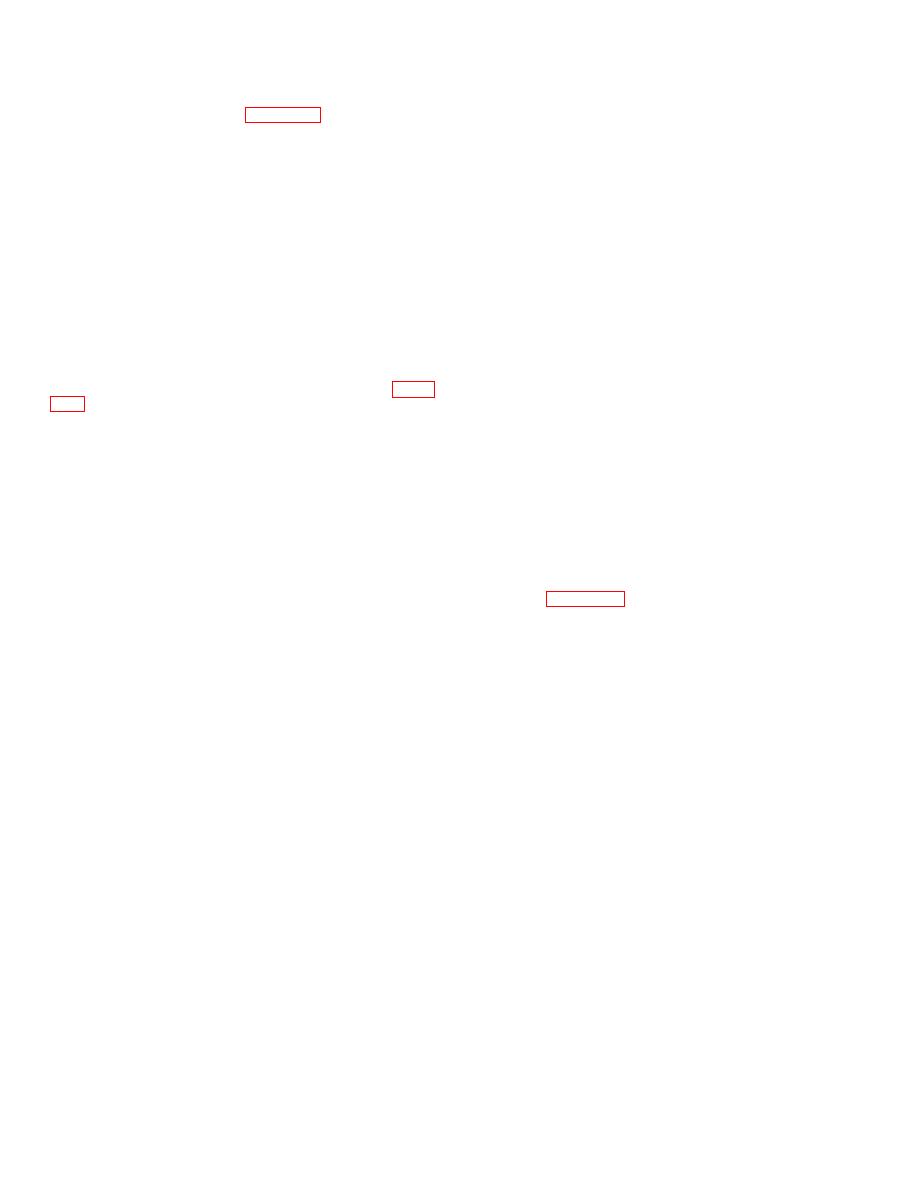

KEY to figure 4-11:

1.

Hose end

13.

Disc holder

24.

Nipple

2.

Street elbow, 90

14.

Nut

25.

Brake knob

3.

Street elbow, 45

15.

Disc

26.

Brake block

4.

Angle valve

16.

Stem

27.

Cap screw (2)

5.

Nut

17.

Valve body

28.

Lock washer (2)

6.

Ident plate

18.

Nut (6)

29.

Retainer

7.

Handwheel

19.

Lock washer (6)

30.

Spindle

8.

Packing nut

20.

Reel end

31.

O-ring (2)

9.

Packing gland

21.

Spacer (6)

32.

Lube fitting

10.

Packing

22.

Tie rod (6)

33.

Pipe plug

11.

Union nut

23.

Reel end

34.

Body

12.

Bonnet

b. Disassembly.

Disassemble the hose reel

c. Cleaning and Inspection. Clean all metal parts

assembly in the numerical sequence shown in figure

with solvent, Federal Specification P-D-680, Type II.

4-11 as follows:

Wipe air service hose clean with cloth moistened with

the solvent.

Inspect all parts for cracks, breaks,

(1) Unscrew and remove hose end (1), street

damaged threads, and distortion. Check shutoff valve

elbows (2, 3), and angle valve (4). When

for proper operation and seating of valve. Inspect hose

disassembly of angle valve (4) is

assembly for any cuts and breaks.

necessary, unscrew and remove nut (5),

identification plate (6), and handwheel (7).

d. Repair. Straighten any distortion of hose reel

Remove packing nut (8), packing gland

ends. Remove any nicks and burrs from spindle with a

(9), and packing (10). Remove union nut

fine crocus cloth. Replace o-rings at each disassembly.

(11) and bonnet (12) from valve body (17).

Replace all defective parts.

Remove stem (16) from valve body (17)

and remove disc holder (13) from stem

e. Reassembly.

Reassemble the hose reel

(16). Remove nut (14) and disc (15) from

assembly in the reverse sequence of index numbers

disc holder (13).

shown in figure 4-11 as follows:

(2) Remove the six nuts (18) and lock

(1) Install pipe plug (33) and lube fitting (32)

washers (19). Remove reel end (20), six

in body (34). Apply a light coating of clean

spacers (21) and tie rods (22), and reel

lubricating oil or petroleum jelly on the two

end (23).

o-rings (31) and assemble in body (34).

Using a twisting motion, assemble spindle

(3) Unscrew and remove nipple (24).

(30) into body (34) being careful not to

Remove brake knob (25) and brake block

damage o-rings (31).

(26).

Unscrew and remove two cap

screws (27) and lock washers (28) ;

(2) Assemble retainer (29) on the end of

remove retainer (29).

spindle (30) with two lock washers (28)

and cap screws (27). Assemble brake

(4) Withdraw spindle (30) from body (34)

block (26) onto body (34) with brake knob

using a twisting motion. Remove two o-

(25). Assemble brake block (26) in one of

rings (31), lube fitting (32), and pipe plug

the slots of retainer (29). Install nipple

(33) from body (34).

(24) in body (34).

(3) Assemble reel end (23) on body (34) with

WARNING

six tie rods (22). Slide six spacers (21)

onto tie rods (22), assemble reel end (20)

Dry cleaning solvent, P-D-680, used

on tie rods (22) with clearance cutout in

to

clean

parts

is

potentially

center bore of reel end over nipple (24).

dangerous

to

personnel

and

Secure reel end (20) on tie rods (22) with

property.

Avoid repeated and

six lock washers (19) and nuts (18).

prolonged skin contact. Do not use

near open flame or excessive heat.

Flash point of solvent is 100 F-130 F

(4) Assemble disc (15) on threaded stem of

(38 C - 59 C).

disc holder (13) and secure with nut (14).

As-

4-29